Plasma display panel without transparent electrode structure and methods for manufacturing upper substrate thereof

A plasma display and transparent electrode technology, applied in the direction of AC plasma display panels, electrode system manufacturing, discharge tube/lamp manufacturing, etc., can solve problems such as glass yellowing, affecting visual effects, silver electrode design difficulties, etc., to achieve structural Fine, anti-yellowing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described below with reference to the drawings and various embodiments, wherein, in each embodiment, the reference numerals of the same components are different.

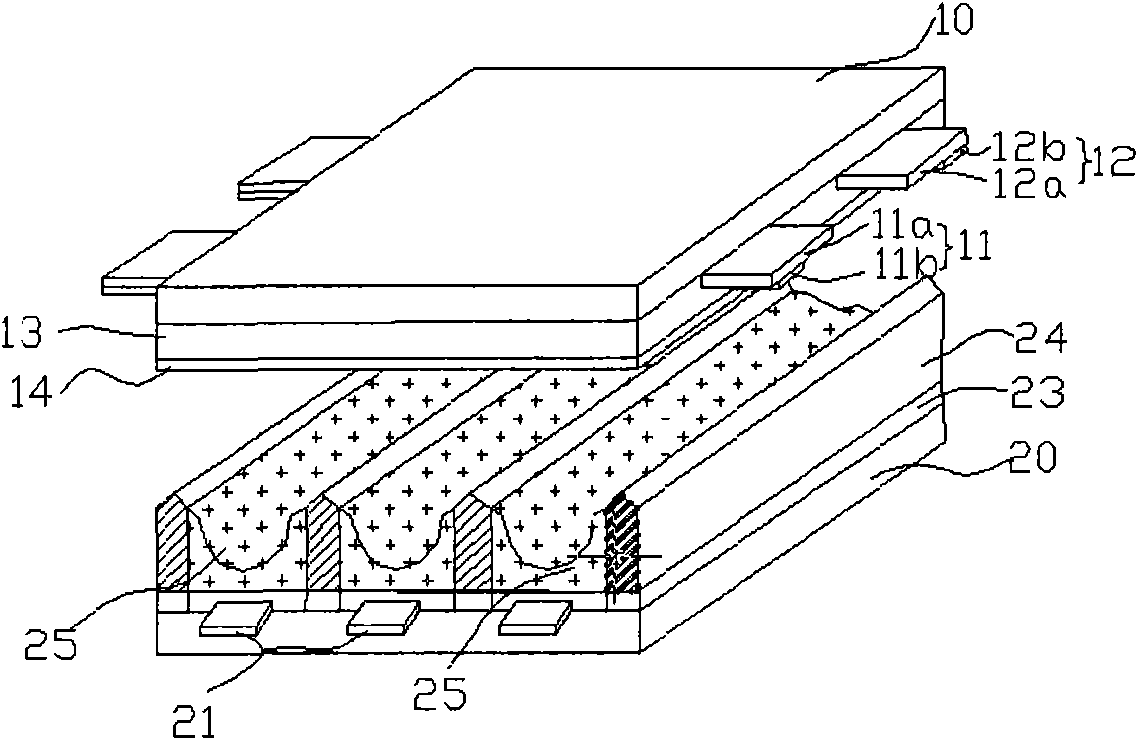

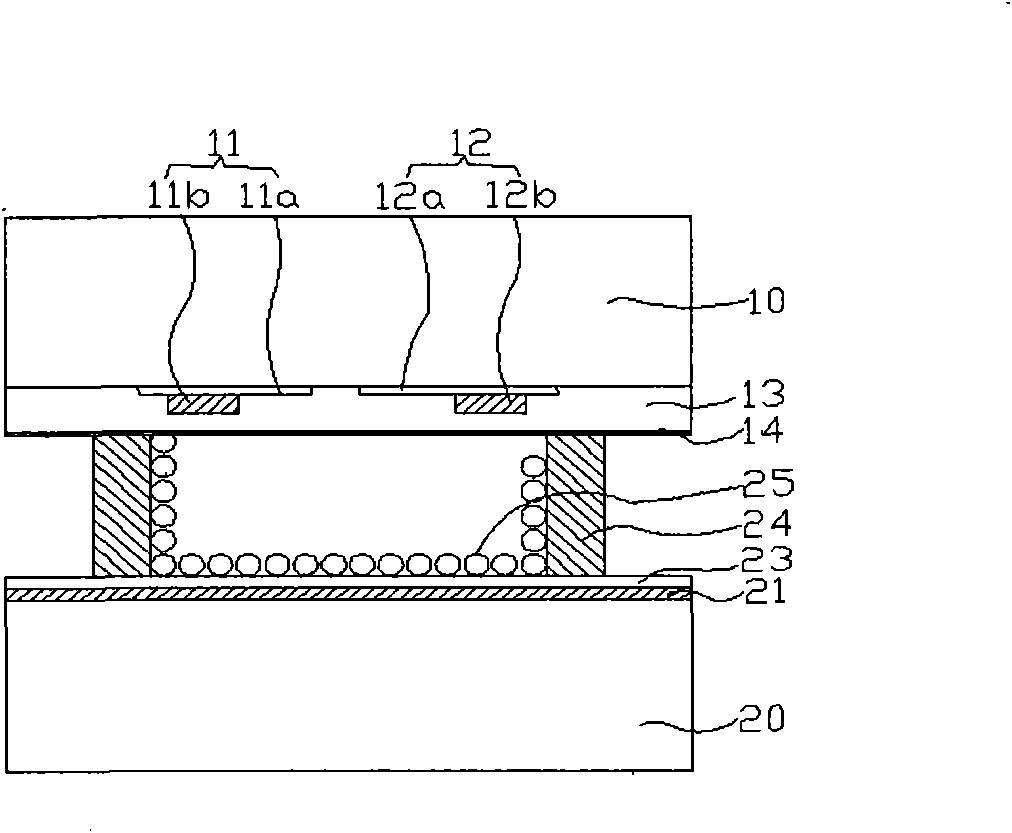

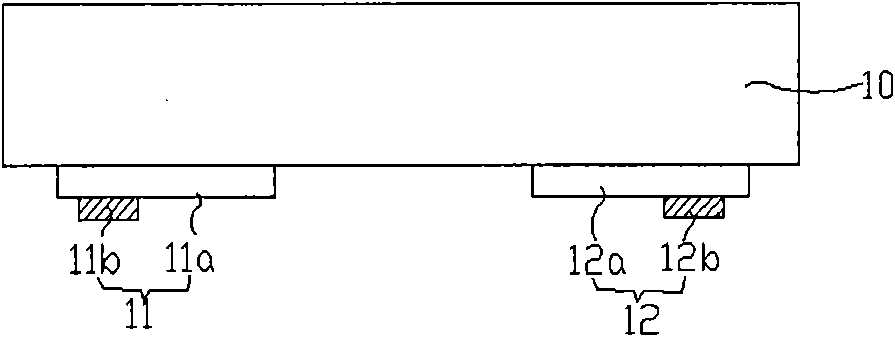

[0032] Figure 4 A schematic plan view showing an ITO-free electrode of a substrate on a plasma display panel according to the present invention. As shown in the figure, there is a first layer of magnesium oxide layer 15 on the upper substrate 10, a silver electrode 11 (silver electrode X) and a silver electrode 12 (silver electrode Y) positioned on the surface of the magnesium oxide layer, formed on the silver electrode 11 and A dielectric layer 13 on the surface of the silver electrode 12 and a second magnesium oxide layer 14 on the surface of the dielectric layer 13 . Wherein, the thickness of the first magnesium oxide layer is 1500 angstroms to 2000 angstroms.

[0033] Figure 5 A schematic plan view showing an ITO-free electrode of a substrate on a plasma display panel ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com