MgO/ ZnO composite dielectric protection film and preparation method thereof

A composite dielectric and protective film technology, which is applied in the manufacture of discharge tubes/lamps, cold cathodes, electrode systems, etc., can solve the problems of not meeting the performance requirements of the dielectric protective film, and achieve the improvement and reduction of the secondary electron emission coefficient Effects of ignition voltage, power consumption and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings.

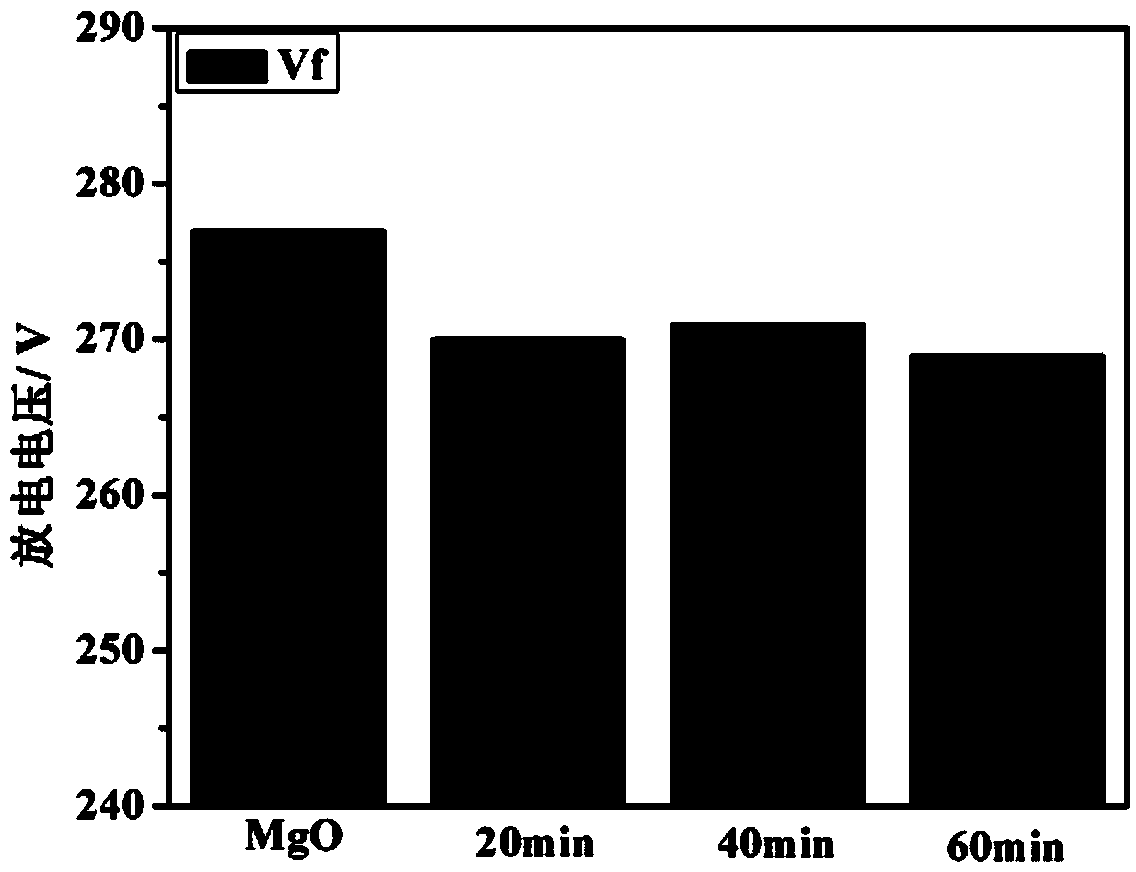

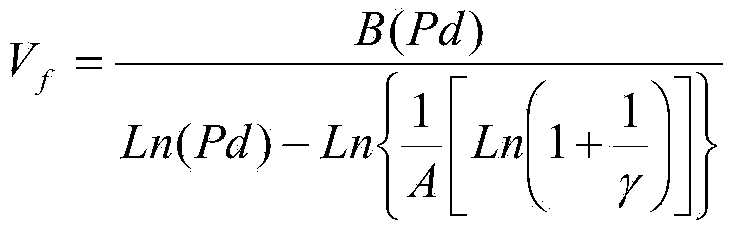

[0032] Such as figure 1 As shown, the present invention provides a kind of MgO / ZnO composite dielectric protection film, and described composite dielectric protection film comprises ZnO nanowire, and the surface of described ZnO nanowire is provided with one deck MgO thin film, and wherein, the length of ZnO nanowire is 50 ~200nm, the thickness of the MgO thin film is 100~500nm. In the present invention, ZnO nanowires are grown on the surface of the substrate on which the ZnO seed layer is prepared by the water bath method, and the ZnO seed layer is obtained by magnetron sputtering, coating and spin coating or pulsed laser deposition; the MgO thin film is obtained by The reactive magnetron sputtering method is sputtered on the surface of ZnO nanowires.

[0033] The present invention also provides a method for preparing a MgO / ZnO composite dielectric protective film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com