Preparation method of ultrapure magnesium oxide powder

A technology of magnesium oxide powder and sodium hydroxide, applied in magnesium oxide, magnesium hydroxide and other directions, can solve the problems of low economic and technical competitiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

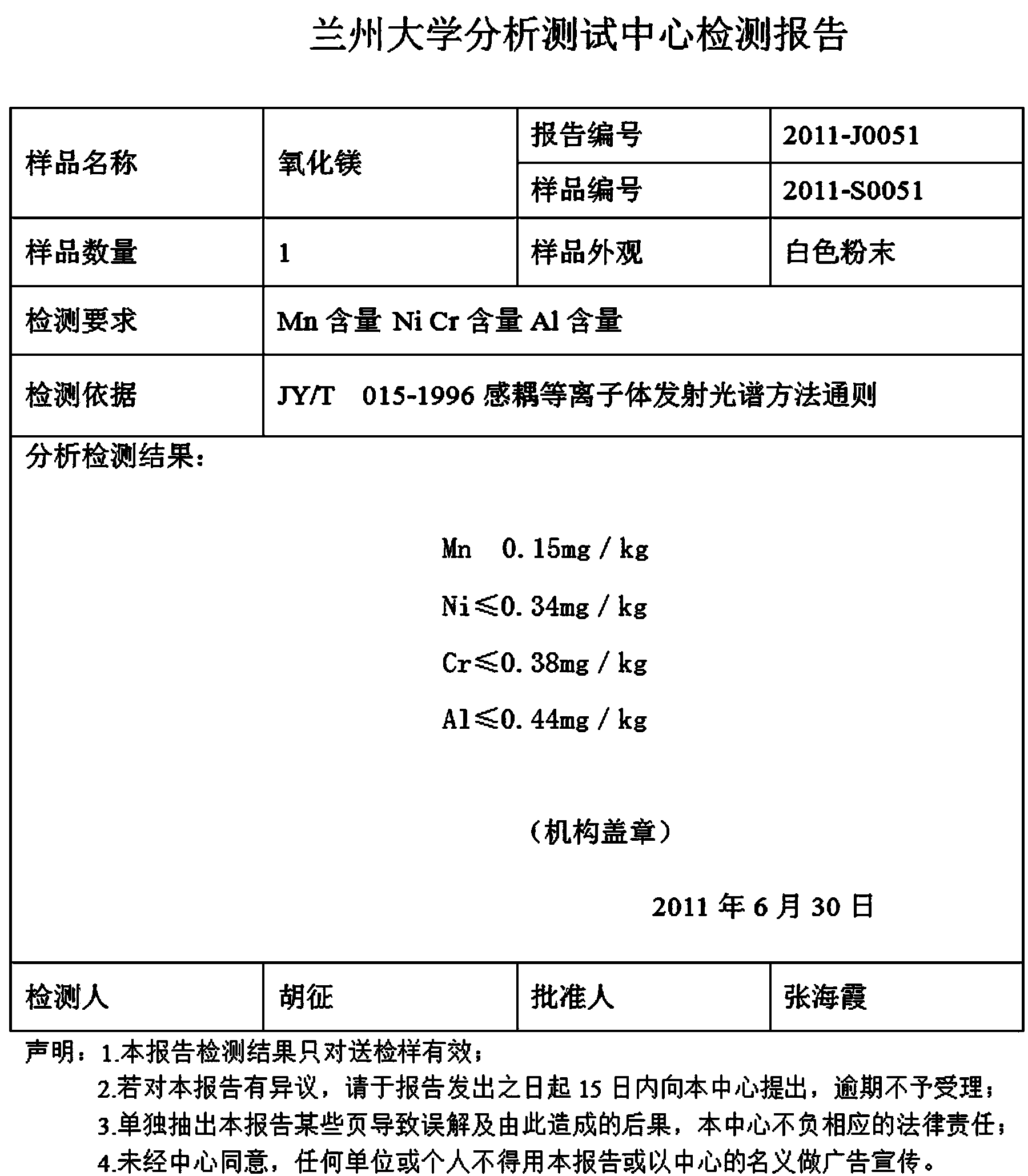

Embodiment 1

[0025] Add magnesium sulfate heptahydrate into pure water with a conductivity of 1.0 μs / cm to completely dissolve, and prepare a 1.5 mol / L magnesium sulfate solution, filter to remove mechanical impurities and insoluble substances; add 0.0000675 mol / L oxalic acid and keep stirring until complete After the reaction produces calcium oxalate precipitate, let it stand and separate until the upper layer becomes a clear liquid, then filter; add 0.00006mol / L hydrogen peroxide dropwise while stirring continuously, and finish adding dropwise within 0.5h, then continue to react for 1h, and stir fully at the same time And acidify, control pH = 4; add 2mol / L sodium hydroxide and keep stirring, after complete reaction, let it stand for 24 hours, extract the supernatant, add it to the polytetrafluoroethylene reactor, keep stirring and heat up After reaching 68°C, add 3.0 mol / L ammonia water dropwise and keep stirring, and the dropwise addition is completed within 4 hours to obtain a magnesiu...

Embodiment 2

[0027] Add magnesium sulfate heptahydrate into pure water with a conductivity of 1.0μs / cm to dissolve completely, and prepare a 2.0mol / L magnesium sulfate solution, filter to remove mechanical impurities and insoluble substances; add 0.0009mol / L oxalic acid and keep stirring until completely After the reaction produces calcium oxalate precipitate, let it stand and separate until the upper layer becomes clear liquid, then filter; add 0.00008mol / L hydrogen peroxide dropwise under constant stirring, finish adding dropwise within 0.8h, then continue to react for 1.5h, and fully Stir and acidify, control pH = 4; add 2.5mol / L sodium hydroxide and keep stirring, let stand for 48 hours after complete reaction, extract the supernatant, add to the polytetrafluoroethylene reactor, keep stirring and After heating up to 70°C, add 4.0 mol / L ammonia water dropwise and keep stirring, and the dropwise addition is completed within 4 hours to obtain a magnesium hydroxide suspension; after the pro...

Embodiment 3

[0029] Add magnesium sulfate heptahydrate into pure water with a conductivity of 1.0 μs / cm to dissolve completely, and prepare a 2.5mol / L magnesium sulfate solution, filter to remove mechanical impurities and insoluble substances; add 0.0001125mol / L oxalic acid and keep stirring until completely After the reaction produces calcium oxalate precipitate, let it stand and separate until the upper layer becomes clear liquid, then filter; add 0.0001 mol / L hydrogen peroxide dropwise under constant stirring, and finish adding dropwise within 1 hour, then continue to react for 2 hours, at the same time fully stir and Acidification, control pH = 4; add 3mol / L sodium hydroxide and keep stirring, after complete reaction, let it stand for 36 hours, extract the supernatant, add it to the polytetrafluoroethylene reactor, keep stirring and heat up to After 72°C, add 5.0 mol / L ammonia water dropwise and keep stirring, and the dropwise addition is completed within 4 hours to obtain a magnesium h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com