Preparation method of multi-dimensional gradient coating layer on surface of cutter

A gradient coating, multi-dimensional technology, applied in coating, metal material coating process, ion implantation plating, etc., can solve the problems of weakening and not considering the interface coating performance, so as to reduce coating failure, raw materials and Low equipment requirements and the effect of solving stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments, wherein the methods are conventional methods unless otherwise specified, and the raw materials can be obtained from open commercial channels unless otherwise specified.

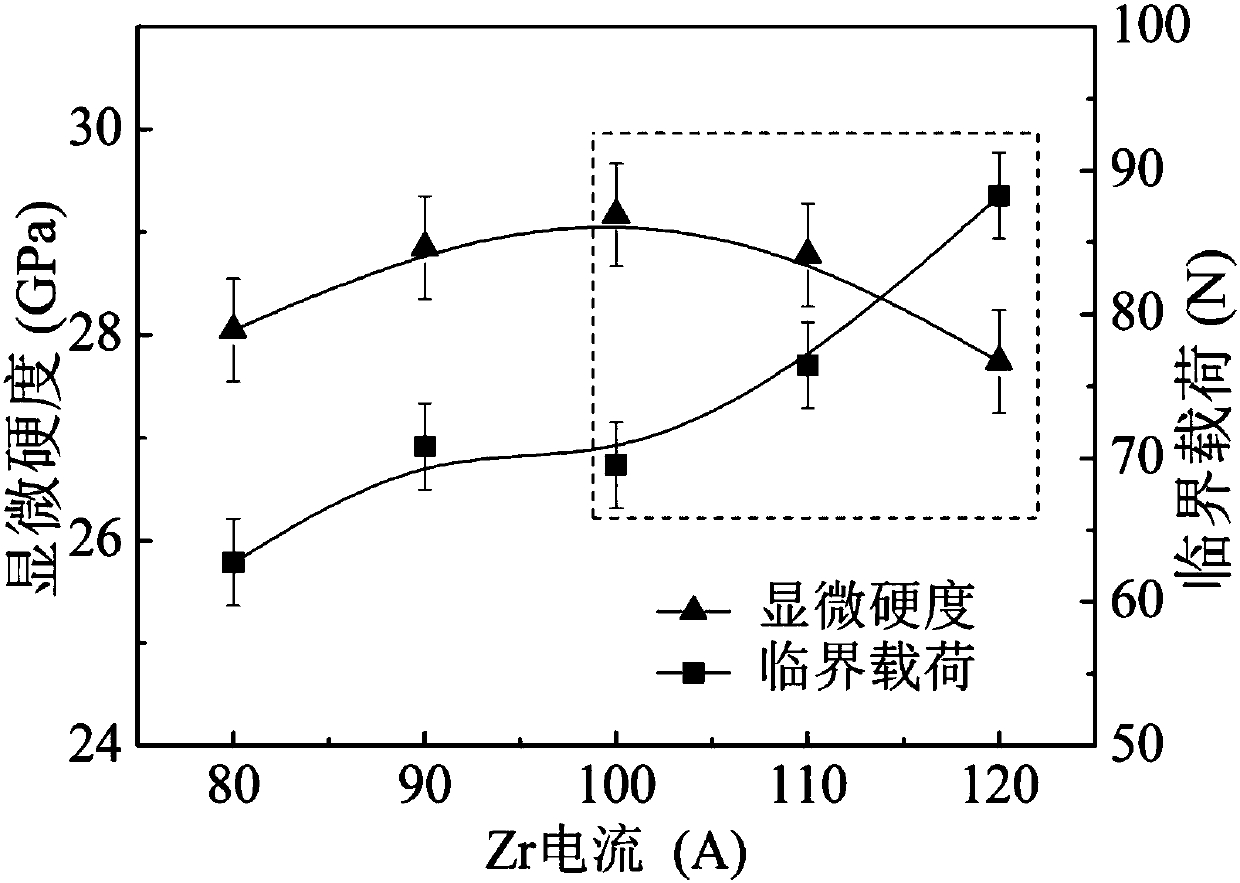

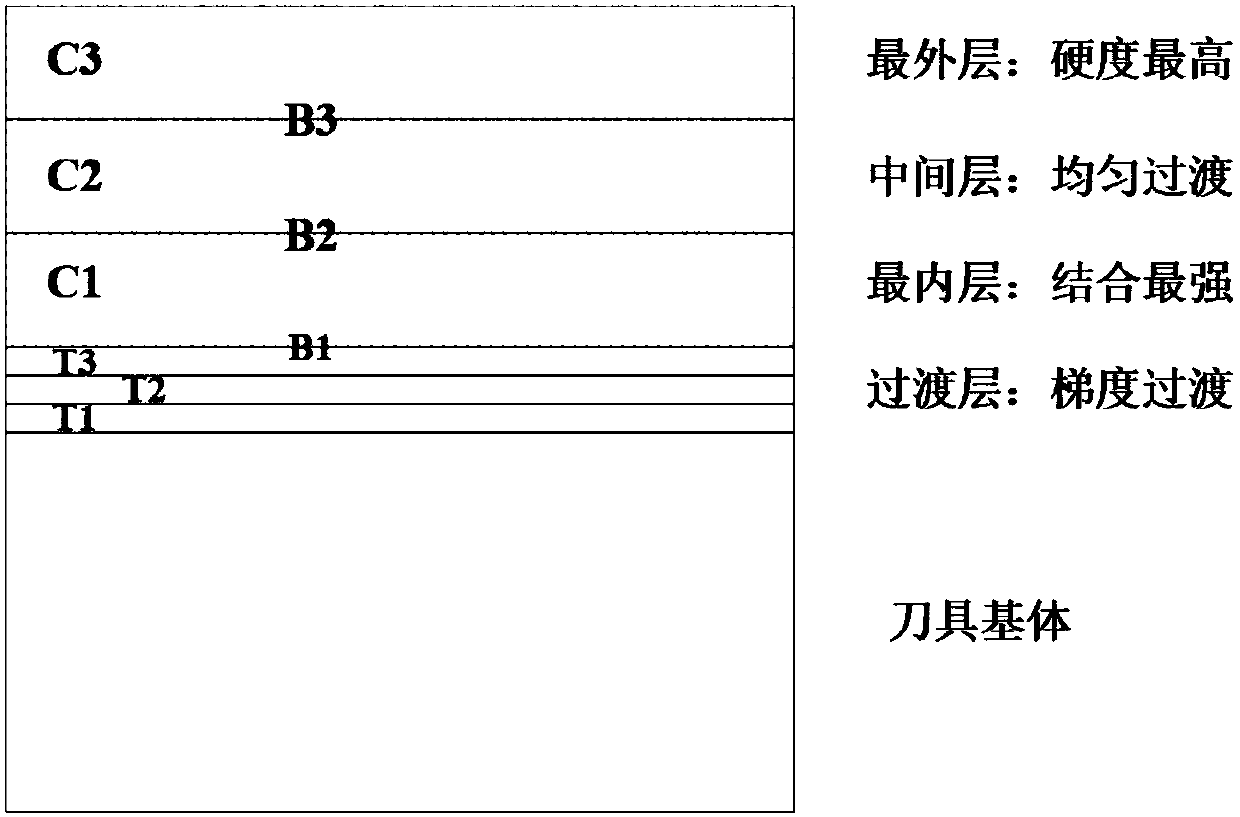

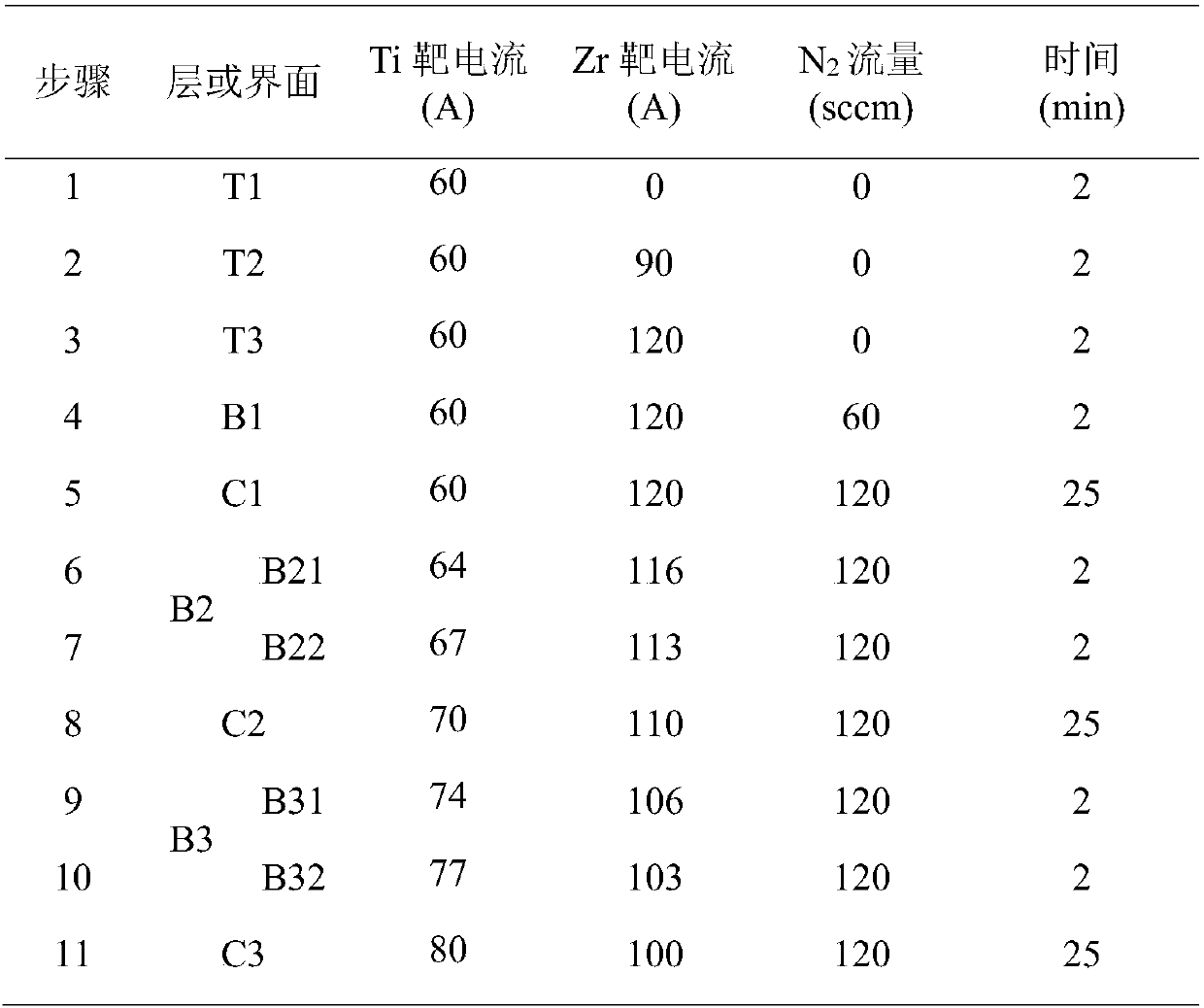

[0039] When multi-arc ion plating technology is used to prepare multi-dimensional gradient coatings on WC-TiC-Co hard alloy tools, the multi-dimensional gradient coatings are divided into Ti-Zr-N coatings, Ti-Zr transition layers and interface Three parts of the transition layer; among them, the Ti-Zr-N coating includes inner, middle and outer layers, and the Ti-Zr transition layer includes inner, middle and outer layers. The distribution of different deposition layers on the tool substrate is detailed in figure 2 ;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com