Small-sized bearing continuous roll-over spraying cleaning device

A technology of spray cleaning device and bearing, which is applied in transportation and packaging, rotary conveyor, cleaning method and utensils, etc., can solve the problems of low turnover efficiency, poor cleaning effect and high cost, so as to reduce cleaning cost and low cost , The effect of reducing equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

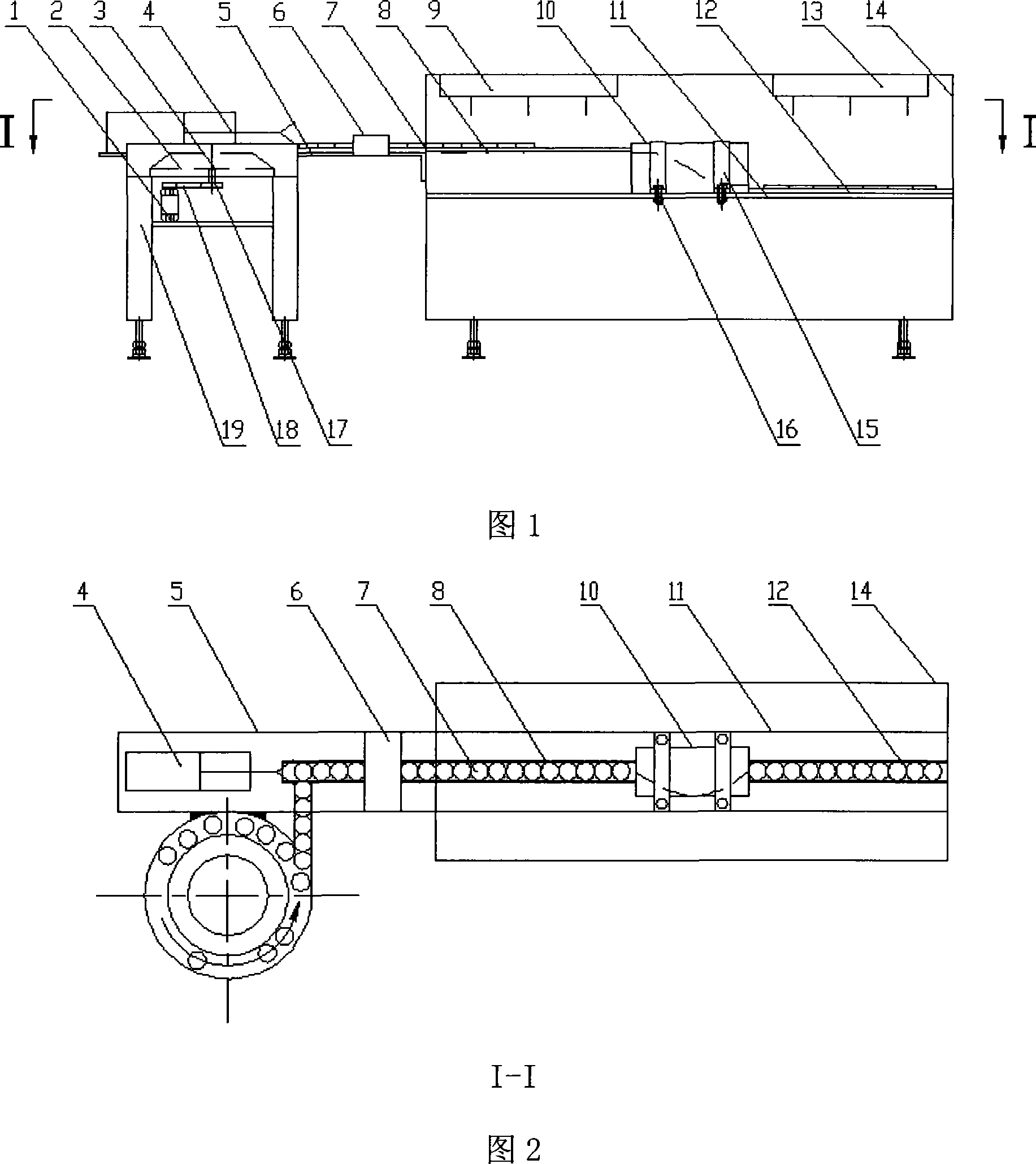

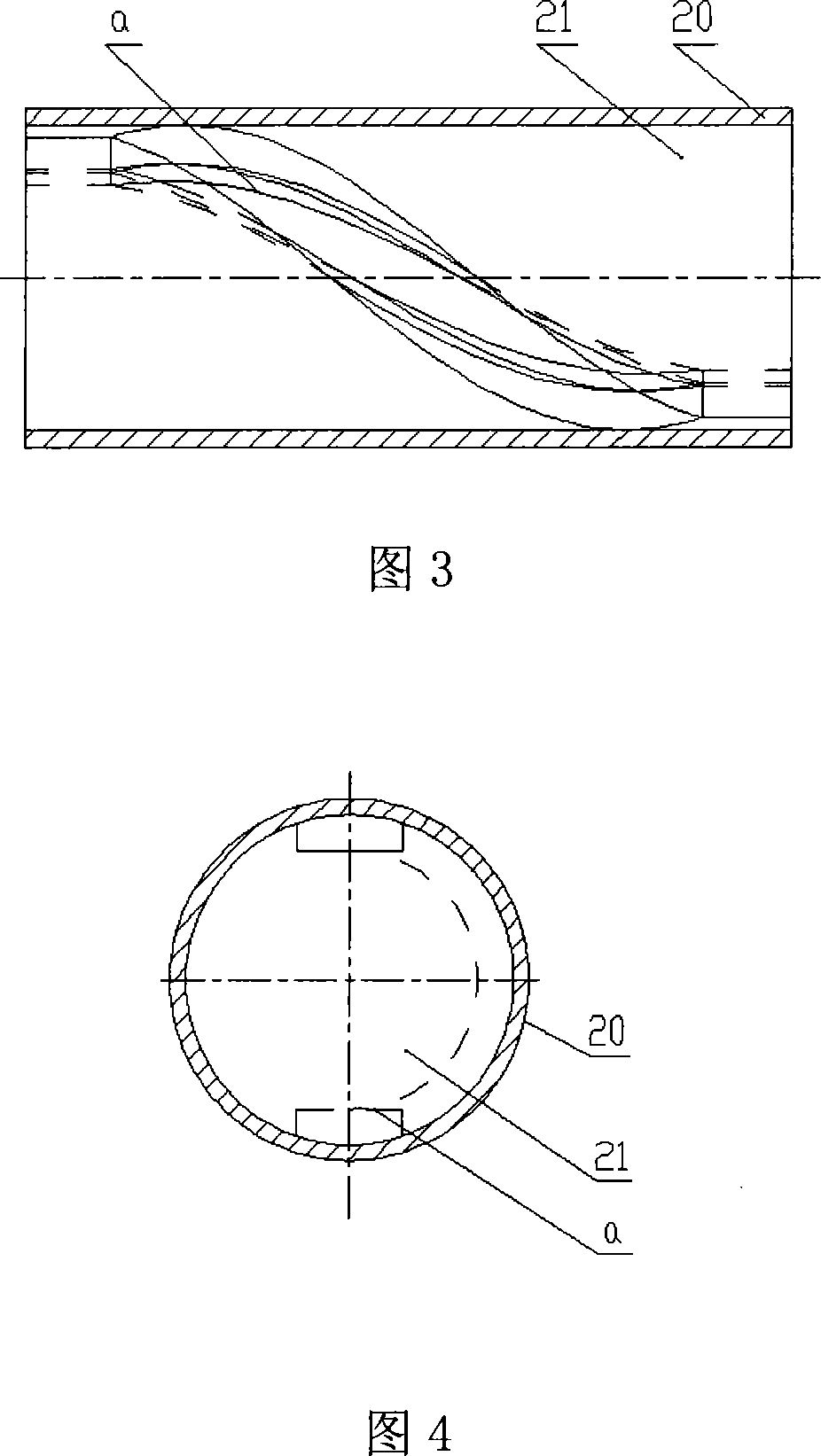

[0010] The specific embodiment of the present invention will be described in detail in conjunction with the accompanying drawings, and the structure of the turner and the entire process will be described. The equipment is composed of two parts: feeding and cleaning. The outer diameter of the cleaned bearing 7 ranges from 5 to 90 mm. The spiral groove size, aspect ratio, cylinder diameter and groove width ratio of the turner 10 are determined according to the outer diameter of the bearing; the groove width of the spiral groove is determined according to the outer diameter of the bearing 7. Depending on the diameter, the width of the groove is slightly greater than the outer diameter of the bearing 7, and the depth of the groove is slightly greater than the height of the bearing 7. Taking the cleaning of a bearing with an outer diameter of 22mm as an example, the structure and size of the turner 10 are determined as follows: the diameter of the turner 10 cylinder is 60.0mm, the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com