Environment-friendly vegetable oil-based polyurethane binder resin, corrugated board ink and preparation method of environment-friendly vegetable oil-based polyurethane binder resin

A binder resin and vegetable oil-based technology, applied in the field of corrugated cardboard printing ink, can solve problems such as difficult to decompose, ink pollution, and difficult to recycle and detach printing ink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Embodiment 1 Preparation of environment-friendly vegetable oil-based polyurethane corrugated cardboard ink

[0077] The preparation process is as follows:

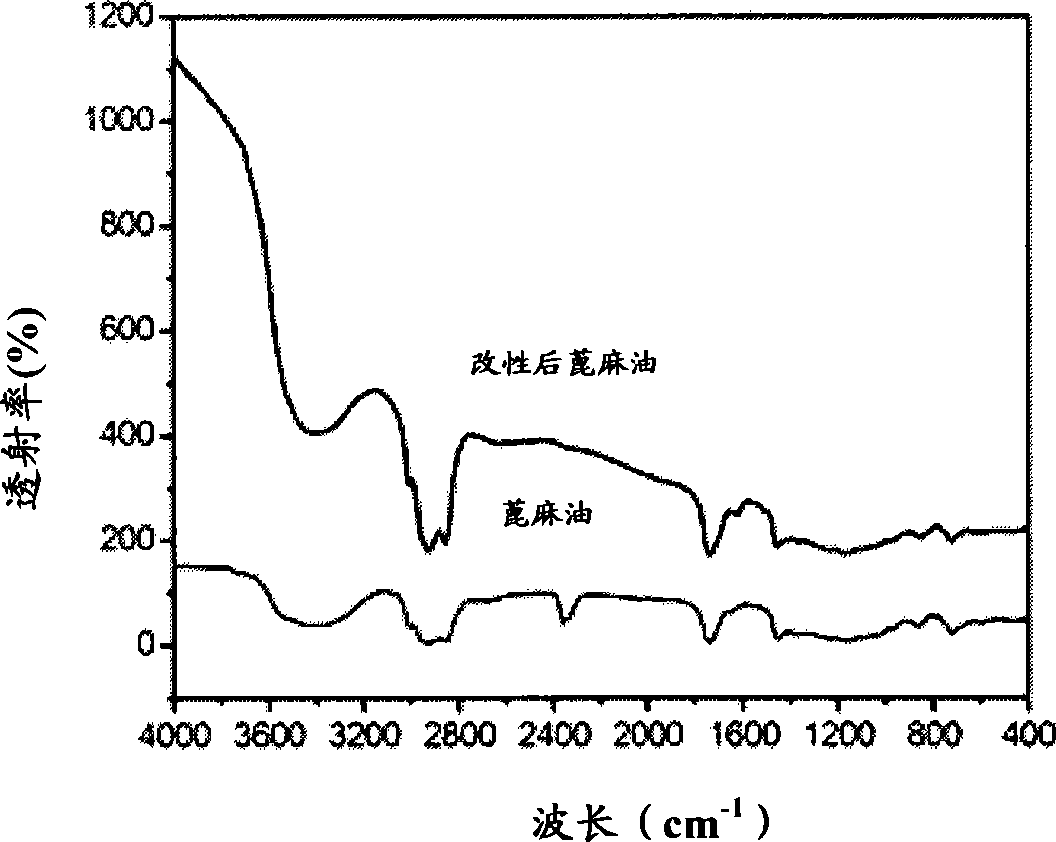

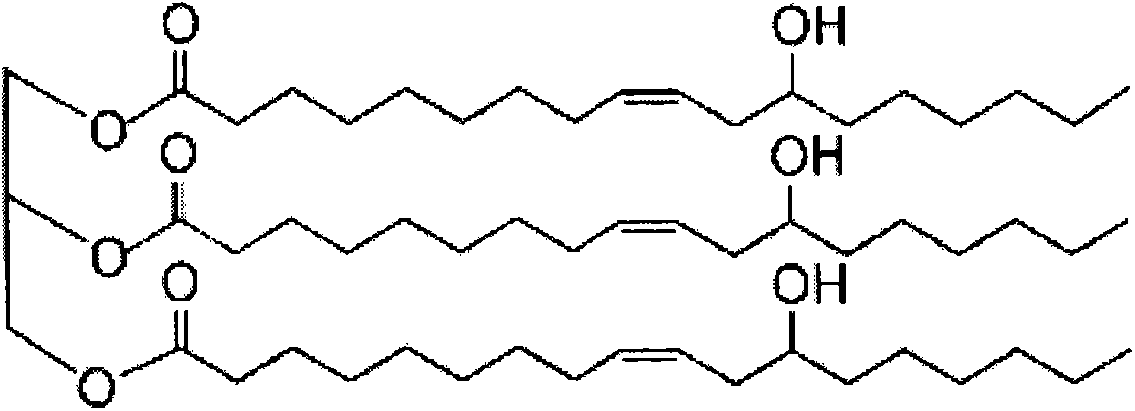

[0078] a. Add 30g of castor oil into a clean beaker with a stirring device, put the beaker into an ultrasonic cleaner, set the temperature at 70°C, and the ultrasonic power at 600W, add 1g of OP-10 to the flask, and stir Mix well; at the same time, take 4g of BMA, 6g of AA and 0.3g of AIBN into a clean empty beaker and use a glass rod to mix and stir to obtain a mixture. Then, when the ultrasonic cleaner started ultrasonic vibration, the mixture was added to the reaction system of castor oil and OP-10. The addition process adopted the method of starvation feeding, and the mixture was added within 2 hours. Obtain the castor oil after polyacrylate monomer modification;

[0079] b. Dry 46.4g of PNA and the modified castor oil in a at 120°C in a drying oven with a vacuum degree of 0.05Mpa for 2 hours, after the drying...

Embodiment 2

[0087] Embodiment 2 Preparation of environment-friendly vegetable oil-based polyurethane corrugated cardboard ink

[0088] The preparation process is as follows:

[0089] a. Add 25g of castor oil into a clean beaker with a stirring device, put the beaker into an ultrasonic cleaner, set the temperature at 65°C, and the ultrasonic power at 600W, add 0.8g of OP-10 to the flask, Stir and mix evenly; at the same time, take 2g of BMA, 3g of AA and 0.1g of AIBN into a clean empty beaker and use a glass rod to mix and stir to obtain a mixture. Then, when the ultrasonic cleaner starts ultrasonic vibration, the mixture is added to the reaction system of castor oil and OP-10, the addition process adopts the method of starvation feeding, and the mixture is added within 1.5 hours. Obtain the castor oil after polyacrylate monomer modification;

[0090] b. Dry 43g of PNA and the modified castor oil in a at 120°C in a drying oven with a vacuum degree of 0.05Mpa for 2 hours, after the drying...

Embodiment 3

[0097] Embodiment 3 Preparation of environment-friendly vegetable oil-based polyurethane corrugated cardboard ink

[0098] The preparation process is as follows:

[0099] b. Add 35g of castor oil into a clean beaker with a stirring device, put the beaker into an ultrasonic cleaner, set the temperature at 80°C, and the ultrasonic power at 600W, add 1.2g of OP-10 to the flask, Stir and mix evenly; at the same time, take 6g of BMA, 8g of AA and 0.5g of AIBN into a clean empty beaker and use a glass rod to mix and stir to obtain a mixture. Then, when the ultrasonic cleaner starts ultrasonic vibration, the mixture is added to the reaction system of castor oil and OP-10, the addition process adopts the method of starvation feeding, and the mixture is added within 2.5 hours. Obtain the castor oil after polyacrylate monomer modification;

[0100] b. Dry 50 g of PNA and the modified castor oil in a at 120° C. in a drying oven with a vacuum degree of 0.05 Mpa for 2 hours, after the dr...

PUM

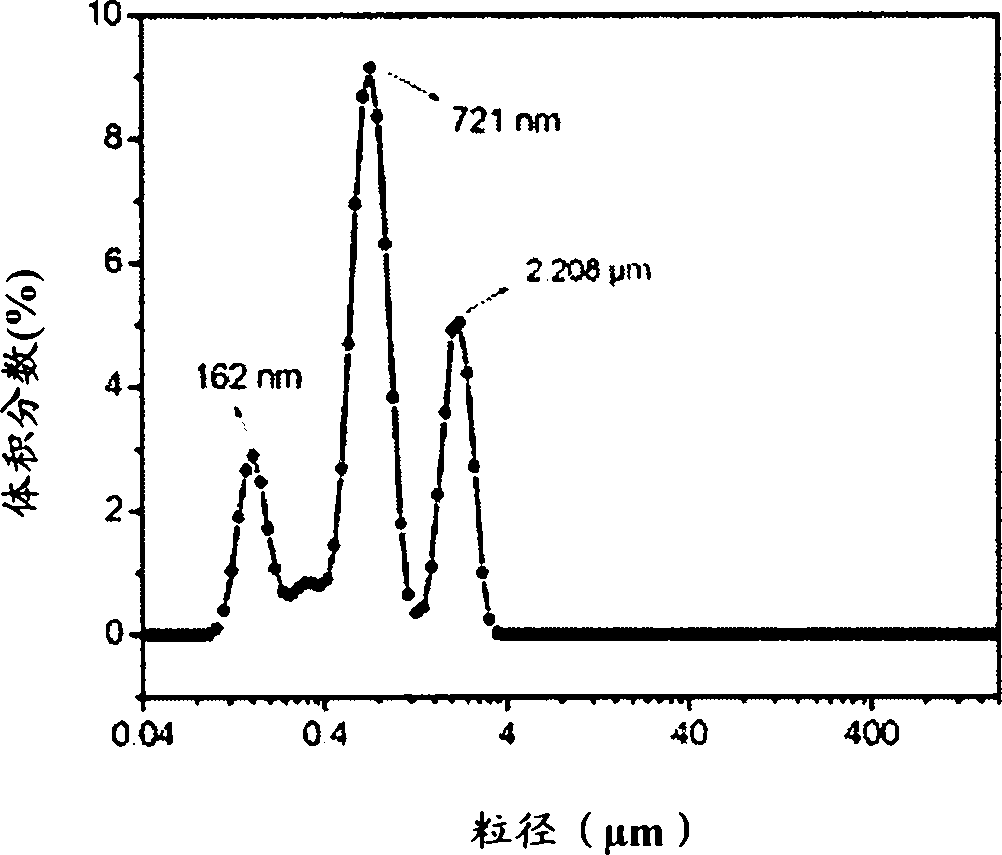

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com