Temperature-sensitive colour-changeable artistic coating and preparation method thereof

An art paint, temperature-sensitive color change technology, applied in the direction of coating, etc., can solve the problems of instability, light resistance, heat resistance, and aging resistance of reversible thermotropic pigments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

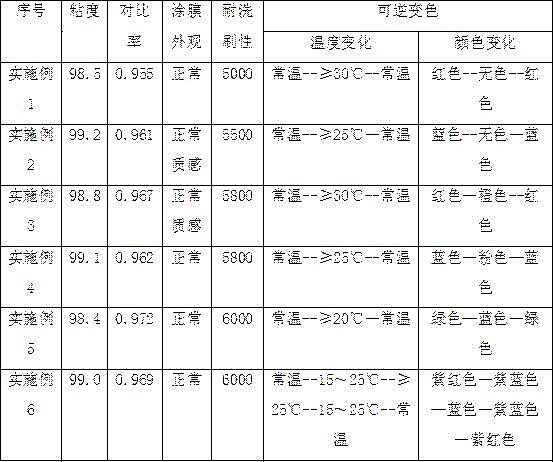

Examples

Embodiment 1

[0064] A temperature-sensitive color-changing art paint, the preparation method of which is as follows:

[0065] (1) Mix and dissolve 26.5 grams of deionized water, 0.7 grams of MP-300 thickener, and 0.2 grams of BS-168 additive, and stir at a speed of 300 r / min for 3 minutes until the MP-300 thickener is completely swollen. Prepare a mixed solution;

[0066] (2) Add 0.6 g of GAST399 dispersant, 0.5 g of X-405 wetting agent, and 0.3 g of 318 defoamer to the mixture obtained in step (1), and stir at a speed of 500 r / min for 3 min to obtain a well-stirred mixed solution;

[0067] (3) Slowly add 15 grams of R-902 titanium dioxide and 10 grams of HS-801A kaolin to the mixed solution obtained in step (2), and stir at a speed of 1500 r / min for 15 minutes to obtain a mixed solution with a fineness ≤ 60 μm;

[0068] (4) Slowly add 0.5 g of EG-CF fungicide, 0.2 g of Troy PP678 antifungal agent, 1.3 g of COASOL film-forming aid and 1.0 g of propylene glycol to the mixture obtained in ...

Embodiment 2

[0074] A temperature-sensitive color-changing art paint, the preparation method of which is as follows:

[0075] (1) Mix and dissolve 22 grams of deionized water, 0.2 grams of MP-300 thickener, and 0.3 grams of BS-168 additive, and stir at a speed of 300r / min for 3 minutes until the MP-300 thickener is completely swollen. Prepare a mixed solution;

[0076] (2) Add 0.5 g of GAST399 dispersant, 0.4 g of X-405 wetting agent, and 0.5 g of 318 defoamer to the mixture obtained in step (1), and stir at a speed of 500 r / min for 3 min to obtain a well-stirred mixed solution;

[0077] (3) Slowly add 20 grams of R-902 titanium dioxide and 8 grams of HS-801A kaolin to the mixed solution obtained in step (2), and stir at a speed of 1500 r / min for 15 minutes to obtain a mixed solution with a fineness ≤ 60 μm;

[0078] (4) Slowly add 0.4 g of EG-CF fungicide, 0.3 g of Troy PP678 fungicide, 1.0 g of COASOL film-forming aid and 0.8 g of propylene glycol to the mixture obtained in step (3), a...

Embodiment 3

[0084] A temperature-sensitive color-changing art paint, the preparation method of which is as follows:

[0085] (1) Mix and dissolve 20.4 g of deionized water, 0.3 g of HS30000YP2 thickener, and 0.1 g of AMP-95 additive, and stir for 3 minutes at a speed of 300 r / min until the HS30000YP2 thickener is completely swollen to obtain a mixed solution ;

[0086] (2) Add 0.5 g of quick-easy dispersant, 0.2 g of DOWEH-9 wetting agent, and 0.2 g of CF439 defoamer to the mixture obtained in step (1), and stir at a speed of 500 r / min for 3 min to obtain a well-stirred the mixture;

[0087] (3) Slowly add 11 grams of 9008 titanium dioxide, 8 grams of Jersey 80L kaolin, and 5 grams of CMS-666 talc to the mixture obtained in step (2), and stir for 15 minutes at a speed of 1500 r / min to obtain a fineness ≤60μm mixed solution;

[0088] (4) Slowly add 0.2 g of K9N fungicide, 0.3 g of Troy PP678 antifungal agent, 1.0 g of alcohol ester-12 film-forming aid and 0.8 g of ethylene glycol to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com