Multicolor infrared low-emissivity environmental protection coating

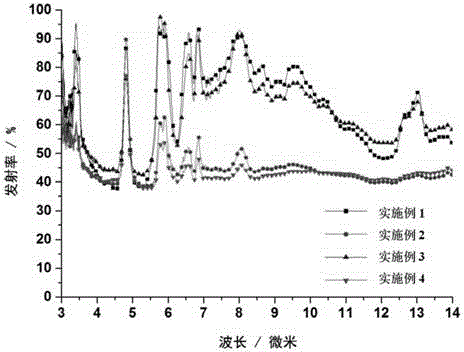

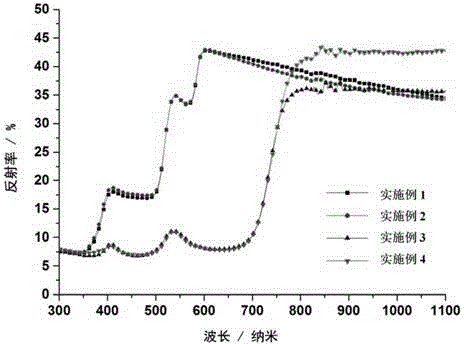

A low-emissivity, colorful technology, applied in camouflage paint, polyurea/polyurethane paint, coating, etc., can solve the problems of unfavorable visible light concealment, strong visible light reflection, and large environmental pollution, and achieve good multi-band compatible camouflage Performance, excellent physical and chemical properties, good film adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1 prepares the environment-friendly coating A of khaki infrared low emissivity

[0023] (1) Preparation of component B

[0024] ①Part B formula

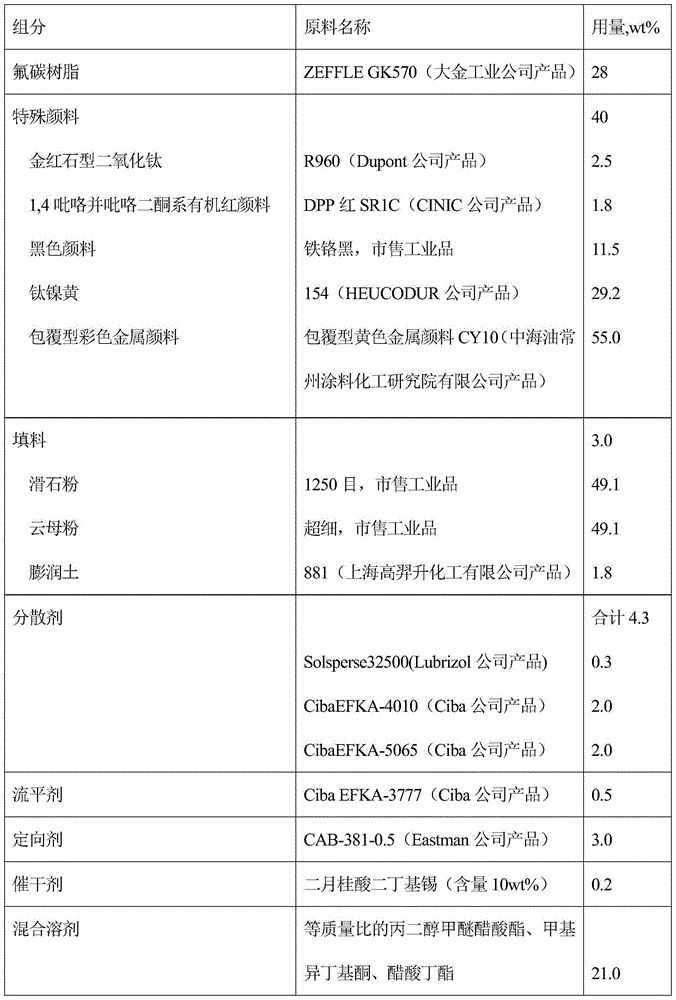

[0025] Component B of Example 1 consists of 28% fluorocarbon resin, 40% special pigment, 3% filler, 4.3% dispersant, 0.5% leveling agent, 3% orientation agent, 0.2% drier, mixed The solvent is composed of 21%, and the special pigment is composed of the following pigments by mass fraction: rutile titanium dioxide 2.5%, 1,4 pyrrolopyrrole diketopyrrole organic red pigment 1.8%, chromium oxide green 0%, titanium nickel yellow 29.2%, black pigment (iron chrome black) 11.5%, coated colored metallic pigment (coated yellow metallic pigment) 55.0%, specific raw materials and their consumption are shown in Table 1.

[0026] Table 1

[0027]

[0028] Note 1: The amount of rutile titanium dioxide, 1,4-diketopyrrolopyrrole organic red pigment, yellow pigment, black pigment, and coated yellow metallic pigment refers to the...

Embodiment 2

[0036] Embodiment 2 prepares the environment-friendly coating B of khaki infrared low emissivity

[0037] (1) Preparation of component B

[0038] ①Part B formula

[0039] Component B of Example 2 consists of 24% fluorocarbon resin, 46% special pigment, 0% filler, 4.1% dispersant, 0.5% leveling agent, 5.2% orientation agent, 0.2% drier, mixed The solvent is composed of 20%, and the special pigment is composed of the following pigments by mass fraction: rutile titanium dioxide 4.8%, 1,4 pyrrolopyrrole diketopyrrole organic red pigment 1.0%, chromium oxide green 0%, titanium nickel yellow 1.0%, black pigment 0%, coated colored metallic pigment (coated yellow metallic pigment) 93.2.%, the specific raw materials and their consumption are shown in Table 2.

[0040] Table 2

[0041]

[0042] Note 1: The amount of rutile titanium dioxide, 1,4 diketopyrrolopyrrole organic red pigment, titanium nickel yellow, and coated colored metallic pigment refers to the percentage of the pigm...

Embodiment 3

[0049] Embodiment 3 prepares the environment-friendly coating A of green infrared low emissivity

[0050] (1) Preparation of component B

[0051] ①Part B formula

[0052] Component B of Example 3 consists of 28% fluorocarbon resin, 40% special pigment, 3% filler, 4.4% dispersant, 0.5% leveling agent, 2.7% orientation agent, 0.2% drier, mixed The solvent is composed of 21.2%, and the special pigment is composed of the following pigments by mass fraction: rutile titanium dioxide 10%, 1,4 pyrrolopyrrole diketopyrrole organic red pigment 2.2%, chromium oxide green 22.5%, titanium nickel yellow 6.2%, black pigment (perylene black) 1.6%, coated colored metallic pigment (coated yellow metallic pigment 45.0%) 57.5%, specific raw materials and their consumption are shown in Table 3.

[0053] table 3

[0054]

[0055]

[0056] Note 1: Rutile titanium dioxide, 1,4 diketopyrrolopyrrole organic red pigments, titanium nickel yellow, chromium oxide green, black pigments, and coated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com