Lithium ion battery waterborne positive electrode composite collector, positive plate, manufacturing methods for lithium ion battery waterborne positive electrode composite collector and positive plate, and lithium ion battery

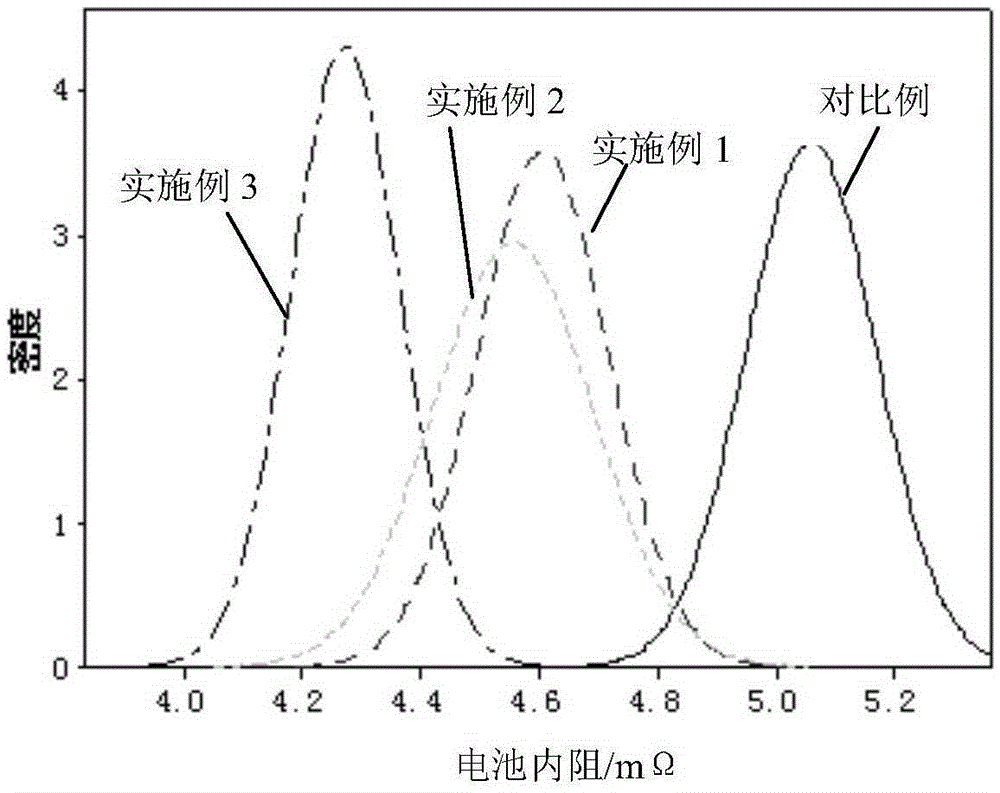

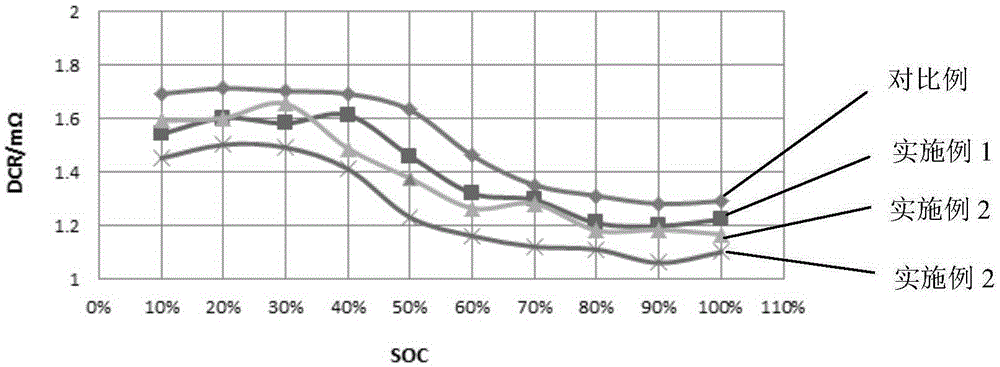

A lithium-ion battery and current collector technology, which is applied in the direction of electrode collector coating, electrode carrier/current collector, electrode manufacturing, etc., can solve the problems of poor flexibility of the positive electrode sheet, cracks on the surface of the electrode sheet, etc., and reduce the internal resistance of the battery , small internal resistance, good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The lithium-ion battery aqueous cathode composite current collector of this embodiment is prepared by a preparation method comprising the following steps:

[0042] 1) Add 1 kg of binder polyvinylidene fluoride (PVDF) into 20 kg of solvent N-methylpyrrolidone, and mix evenly to obtain a binder solution;

[0043] 2) Add 9kg of conductive agent SuperP to the binder solution prepared in step 1), mix well, grind and emulsify at a speed of 1000rpm with a grinding ball of 0.4mm particle size for 2h, remove foam for 8h, and pass through a 200-mesh sieve Net, get conductive paste;

[0044] 3) Use a gravure printing machine to evenly coat the conductive paste prepared in step 2) on both surfaces of the positive electrode current collector aluminum foil, the thickness of the aluminum foil is 20 μm, and the coating surface density is 2g / m 2 , dried at 120 ° C, that is, too.

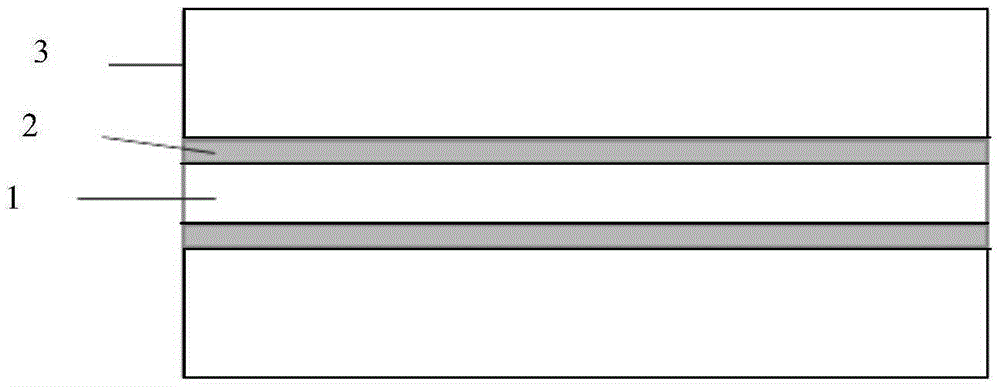

[0045] Such as figure 1 As shown, the positive electrode sheet of this embodiment includes the above-men...

Embodiment 2

[0050] The lithium-ion battery aqueous cathode composite current collector of this embodiment is prepared by a preparation method comprising the following steps:

[0051] 1) Add 200g of binder carboxymethylcellulose sodium (CMC) into 15kg of solvent deionized water, mix evenly, then add 1.4kg of polyvinyl alcohol, mix evenly, and obtain a binder solution;

[0052] 2) Add 2.4kg of conductive agent SuperP to the binder solution prepared in step 1), mix well, grind and emulsify at a speed of 1000rpm with 0.6mm grinding balls for 2h, defoam for 8h, pass through 200 mesh screen to obtain conductive paste;

[0053] 3) Use a gravure printing machine to evenly coat the conductive paste prepared in step 2) on both surfaces of the positive electrode current collector aluminum foil, the thickness of the aluminum foil is 10 μm, and the coating surface density is 1 g / m 2 , dried at 70 ° C, that is, too.

[0054] The positive electrode sheet of this embodiment includes the above-mentioned...

Embodiment 3

[0059] The lithium-ion battery aqueous cathode composite current collector of this embodiment is prepared by a preparation method comprising the following steps:

[0060] 1) Add 200g of binder sodium carboxymethylcellulose (CMC) into 15kg of solvent deionized water, mix evenly, then add 1.4kg of styrene-butadiene rubber (SBR), mix evenly, and obtain a binder solution;

[0061] 2) Add a mixed conductive agent mixed with 800g SuperP and 1600g graphene to the binder solution prepared in step 1), mix evenly, and grind and emulsify for 2h at a speed of 1000rpm with a grinding ball with a particle size of 0.3mm, except Soak for 8 hours, pass through a 200-mesh sieve to obtain conductive paste;

[0062] 3) Apply the conductive paste prepared in step 2) evenly on both surfaces of the positive electrode current collector aluminum foil with a gravure printing machine, the thickness of the aluminum foil is 25 μm, and the coating surface density is 1 g / m 2 , dried at 70 ° C, that is, too...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com