Coating method of cold-rolled silicon steel chromium-free insulating coatings, coating rubber roll and coating liquid

An insulating coating, cold-rolled silicon steel technology, applied in the coating, the device for coating liquid on the surface, the surface pretreatment, etc., can solve the problems of few coating methods, difficult to achieve the expected effect, etc., and achieve excellent punching and shearing performance. , good anti-rust performance, uniform color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

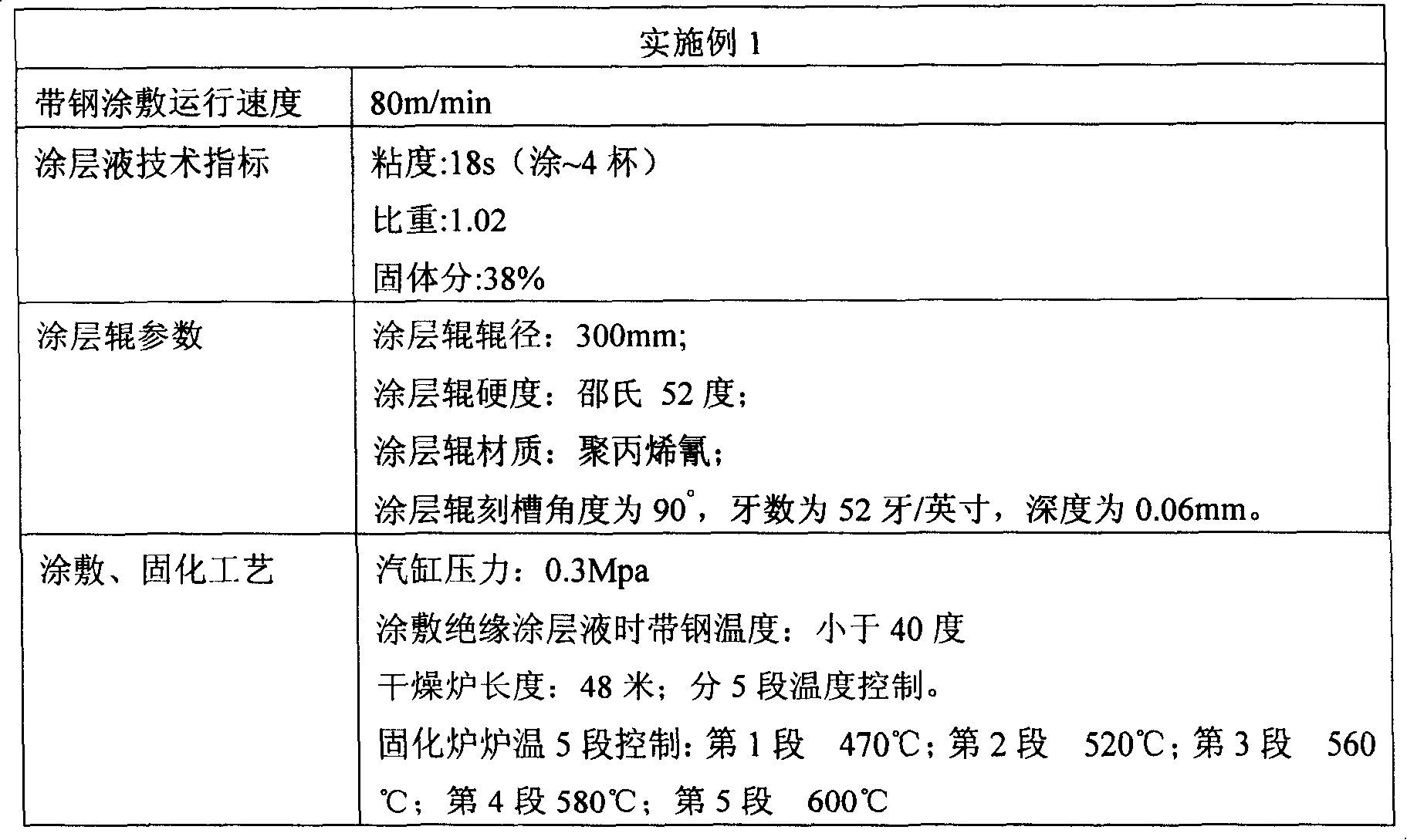

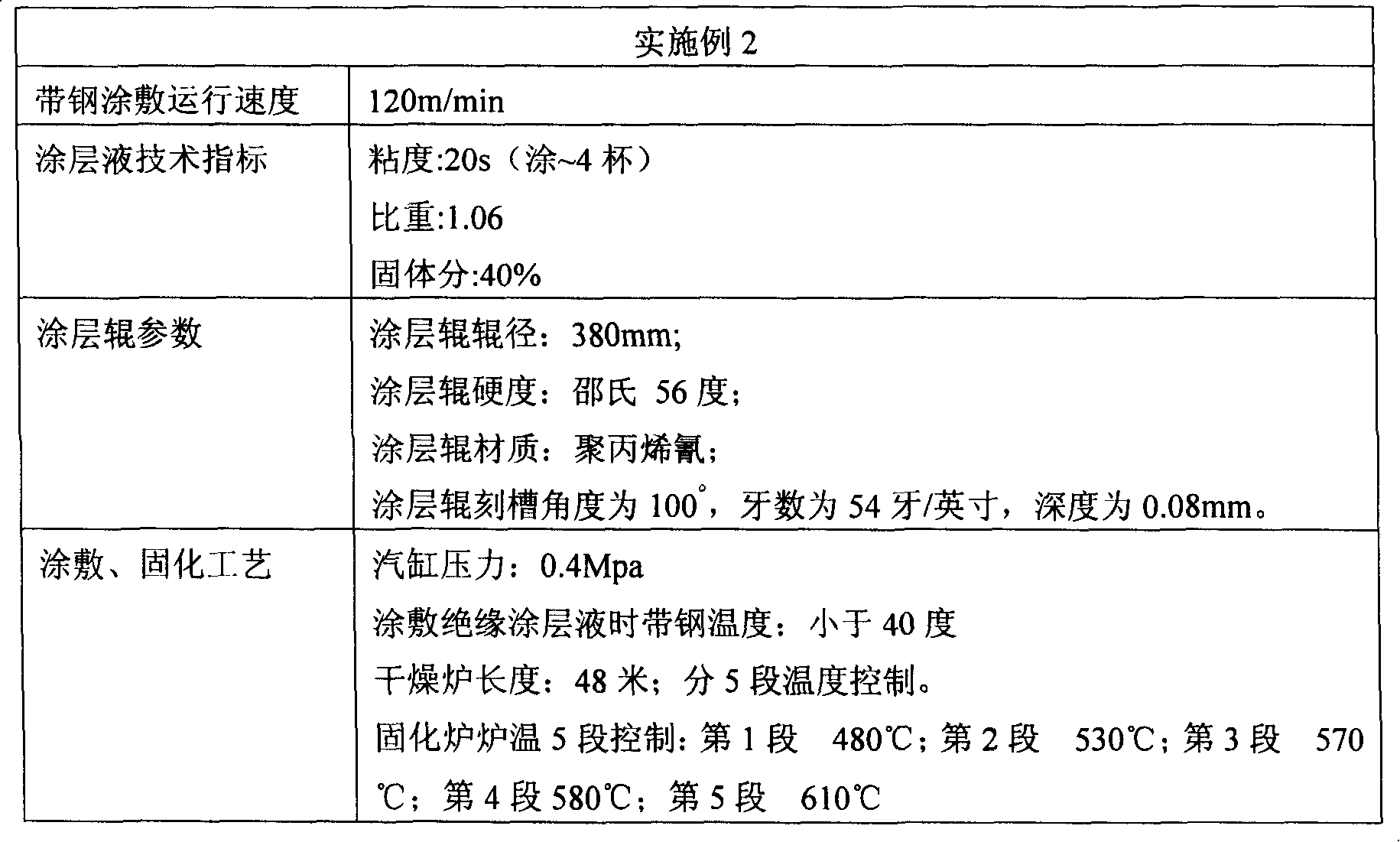

[0019] The present invention at first prepares coating raw material, buys the water-dispersed chrome-free one-component insulating coating liquid that sells in the market according to the following requirements, and its component content is acrylic resin 30%~75%; Curing agent 15%~35%; Inorganic Pigment 8% to 60%; additives account for 0% to 2% of the ingredients, add water-dispersed acrylic resin, inorganic pigment, curing agent, water to the paint preparation container at a uniform speed according to the formula amount, disperse evenly, and then add disinfectant as needed Foaming agent, preservative, leveling agent and rheology regulator, after mixing evenly, filter with 180 mesh screen, choose high etherified amino resin or other curing agent as curing agent. The physical and chemical indicators of the insulating coating liquid must be guaranteed: viscosity 18-30s (coating ~ 4 cups); solid content 38% ~ 42%; PH: 5 ~ 7; specific gravity 1.01 ~ 1.15.

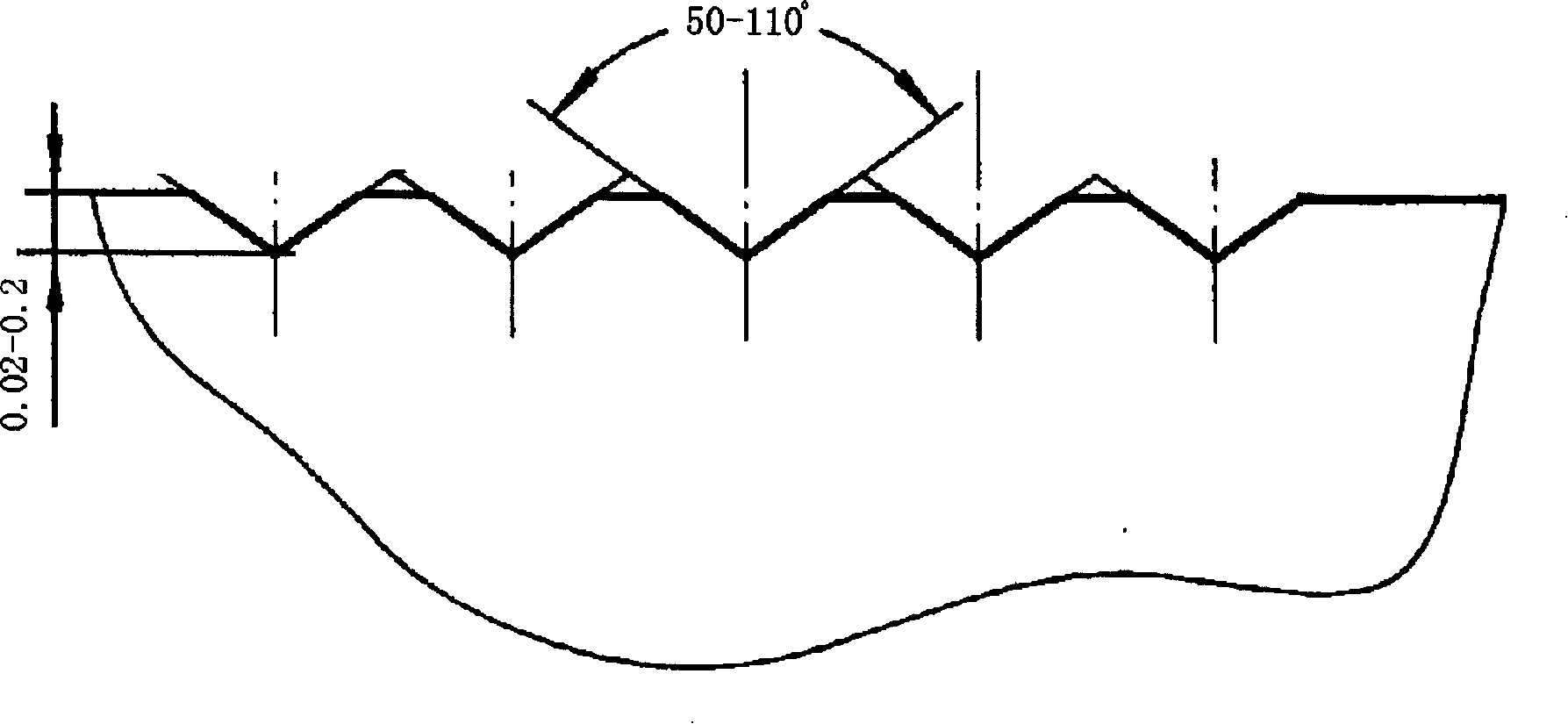

[0020] The coating solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com