Vegetable fiber environmental protection material product and preparation method thereof

A plant fiber and environmental protection material technology, applied in the field of plant fiber environmental protection material products, can solve the problems of poor toughness of plant fiber environmental protection material products, reduce the yield of plant fiber environmental protection material products, difficulty in preparation of plant fiber environmental protection material products, etc., and achieve the color of the finished product Smooth and well-proportioned, good toughness, and the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

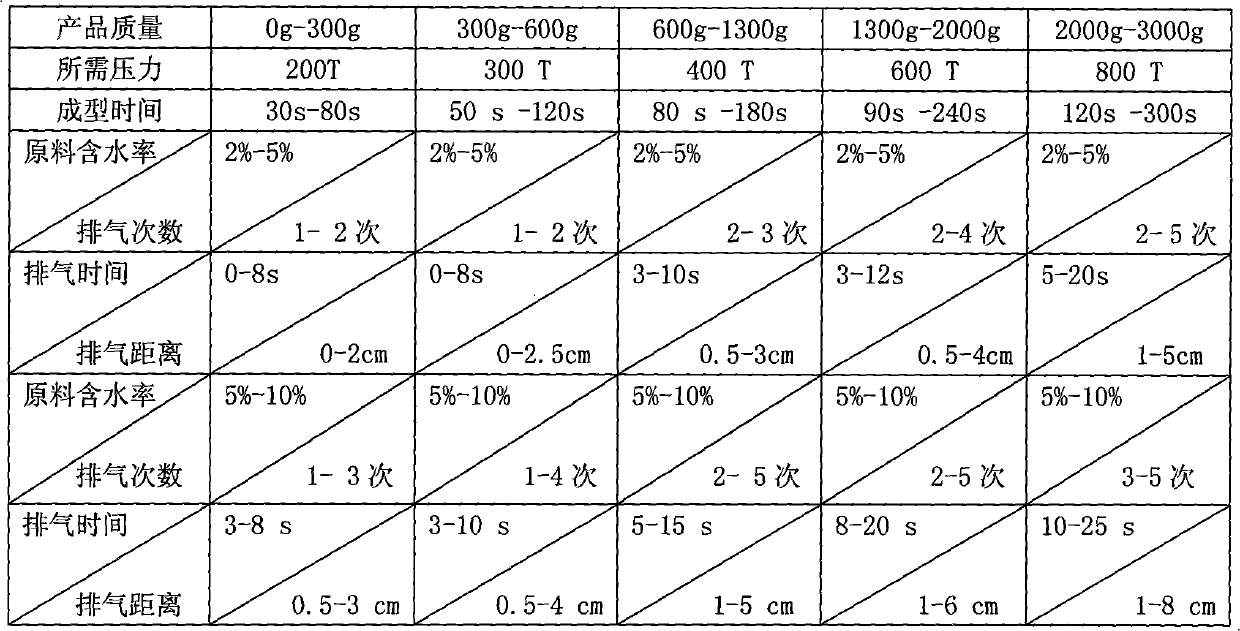

Embodiment 1

[0019] Plant fiber environmental protection material products are prepared from the following raw materials in parts by mass: 51 parts of plant fiber, 21 parts of electric jade powder, 10 parts of tapioca starch, 1 part of paraffin, 0.5 parts of sodium benzoate, 1.5 parts of zinc stearate, 1 part of antibacterial Oxygen agent 1010, 2 parts of organic pigments, 1 part of maltose, 4 parts of dextrin, 5 parts of light calcium carbonate, 2 parts of titanium dioxide, 0 parts of edible oil.

[0020] The preparation method of the above-mentioned plant fiber environmental protection material product comprises the following steps:

[0021] a. Grinding the plant fiber to 80 meshes to obtain plant fiber powder, at room temperature, place the plant fiber powder in a high-speed mixer and stir for 20 minutes to make it evenly mixed, wherein the water content of the plant fiber powder is 2%;

[0022] b. After adding binder, starch dextrin, maltose, release agent, waterproofing agent, organic...

Embodiment 2

[0025] Plant fiber environmental protection material products are prepared from the following raw materials in parts by mass: 20 parts of plant fiber, 40 parts of electric jade powder, 10 parts of tapioca starch, 1.5 parts of paraffin, 0.5 parts of sodium benzoate, 1 part of zinc stearate, 1 part of antibacterial Oxygen agent 1010, organic pigment 5 parts, titanium dioxide 1 part, dextrin 10 parts, maltose 10 parts, light calcium carbonate 0 parts, edible oil 0 parts.

[0026] The preparation method of the above-mentioned plant fiber environmental protection material product comprises the following steps:

[0027] a. Grinding the plant fiber to 30 meshes to obtain plant fiber powder, at normal temperature, place the plant fiber powder in a high-speed mixer and stir for 30 minutes to make it evenly mixed, wherein the water content of the plant fiber powder is 5%;

[0028] b. After adding binder, starch dextrin, maltose, release agent, water repellant, organic pigment or food co...

Embodiment 3

[0031] Plant fiber environmental protection material products are prepared from the following raw materials in parts by mass: 40 parts of plant fiber, 25 parts of electric jade powder, 5 parts of melamine, 15 parts of tapioca starch, 1 part of paraffin, 0.5 parts of sodium benzoate, 1.5 parts of zinc stearate 1 part, 1 part antioxidant 1010, 1 part organic pigment, 1 part maltose, 8 parts light calcium carbonate, 1 part edible oil, 0 part titanium dioxide.

[0032] The preparation method of the above-mentioned plant fiber environmental protection material product comprises the following steps:

[0033] a. Grinding the plant fiber to 120 meshes to obtain plant fiber powder, at room temperature, place the plant fiber powder in a high-speed mixer and stir for 40 minutes to make it evenly mixed, wherein the water content of the plant fiber powder is 7%;

[0034] b. After adding binder, starch dextrin, maltose, release agent, waterproofing agent, organic pigment or food coloring, p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com