Solar heat absorbing paint and manufacturing method thereof

A technology of solar energy absorption and production method, applied in the field of coatings, can solve problems such as high cost and complex solar collector technology, and achieve the effects of strong coating adhesion, high stability and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

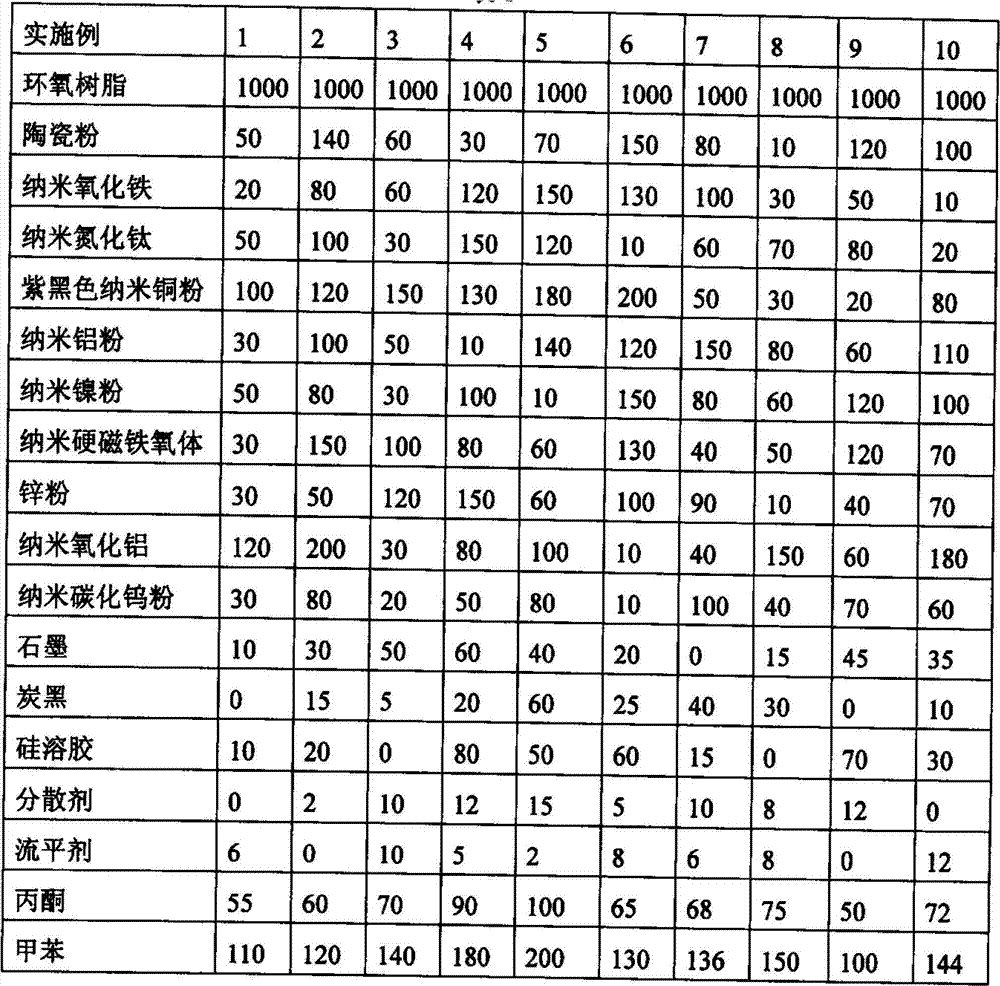

[0029] The formula (weight unit is gram) of 10 embodiments has been listed in table 1, and its preparation method is all: at normal temperature, the solid powder of batching quantity is mixed with epoxy resin, dispersant, leveling agent, organic The liquid components in the solvent and other formulas are mixed, fully dispersed and stirred evenly; then filtered, sealed in a can.

[0030] Table 1

[0031]

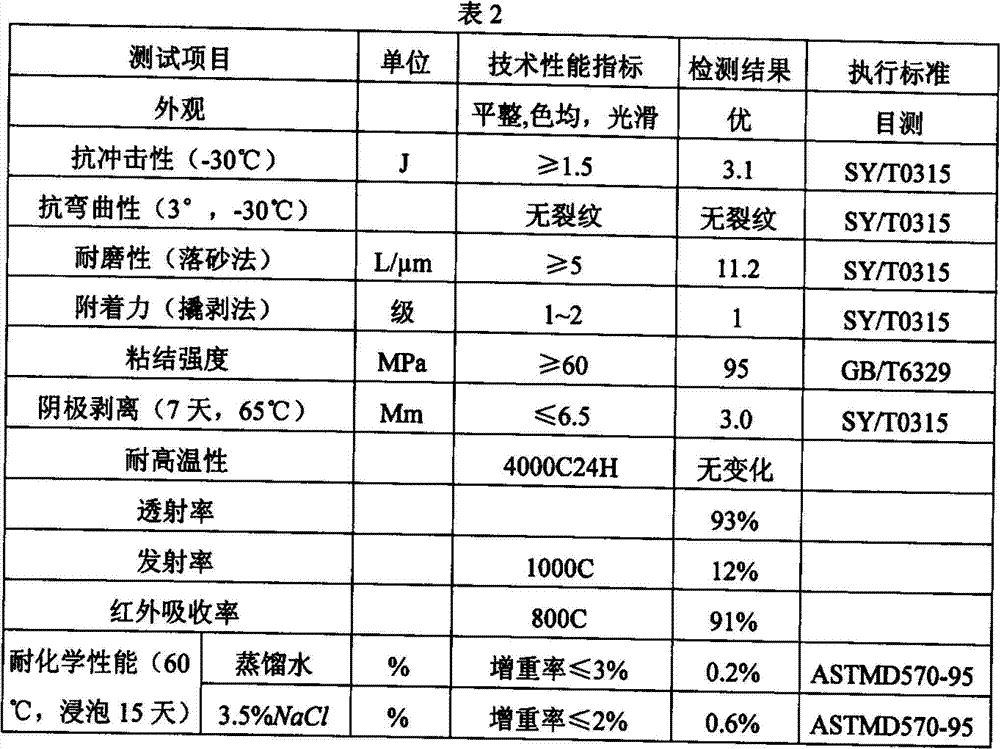

[0032] The coating of the present invention is a special coating for absorbing solar energy. It is used alone and directly sprayed or brushed on the inner surface of the heat-absorbing vacuum glass tube or the surface of the heat-absorbing metal layer of the flat solar heat collector at normal temperature. Before spraying the coating, it needs Clean the glass or metal surface, make the metal surface reach the natural color of the metal, and stir the paint evenly, and then paint the paint with a thickness of 40-160μm or thicker according to the type of collector.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com