Acrylic amide modified polymer micro-crosslinking gel and preparation thereof

A technology of micro-crosslinked gel and acrylamide, which is applied in the fields of polymer materials and oil field chemistry, and can solve problems such as poor salt resistance, short validity period, and low system elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

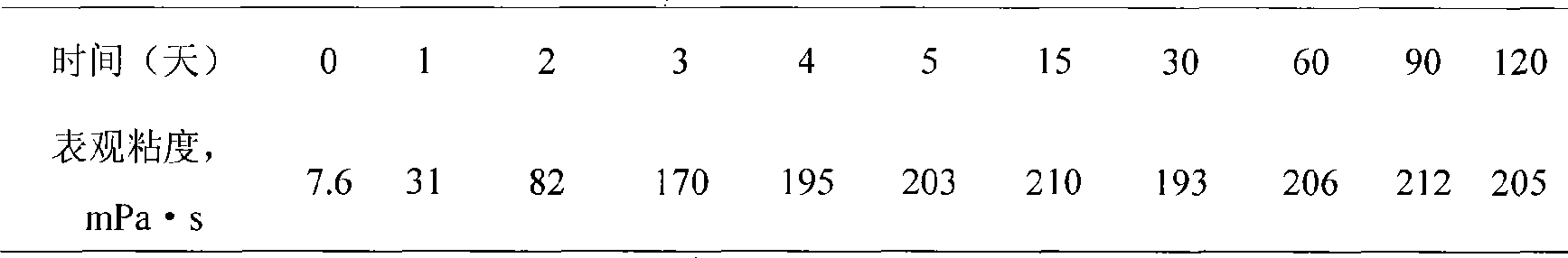

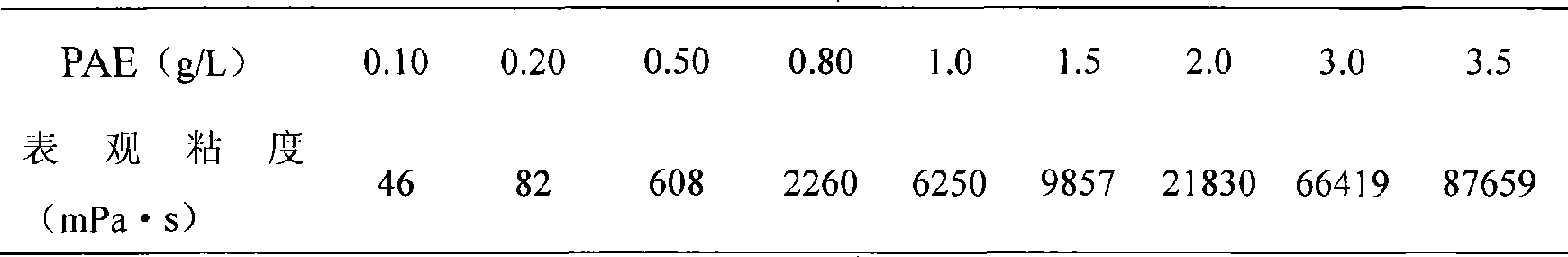

Embodiment 1

[0028] Dissolve 20.000 g of acrylamide, 8.042 g of acrylic acid, and 1.800 g of 4-vinylbenzyl octylphenol polyoxyethylene ether (the adduct of polyoxyethylene ether is 40) in 380 mL of distilled water, add it to a three-necked reaction flask, and use The pH of the solution was adjusted to 8 with NaOH, the reaction temperature was 65 °C, and N was passed through. 2 30min, add 6.50mL of 0.05mol / L potassium persulfate initiator solution, react for 32h, dilute the polymer with water to obtain a concentrated PAE solution. A certain amount of polymer PAE was taken to prepare a sample of oil-displacing agent aqueous solution, and the sample was colorless and transparent. The polymer concentration was 0.5g / L, the aluminum citrate concentration was 0.15g / L, the sodium dodecylbenzenesulfonate concentration was 0.3mmol / L, and the sodium sulfite concentration was 0.03g / L. The aqueous solution was added with a stirring device. In the mixing container of , the solution is stirred evenly at...

Embodiment 2

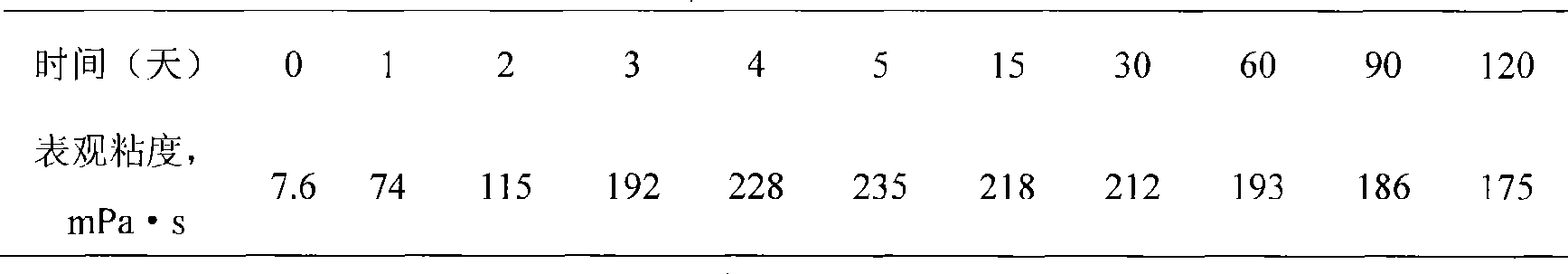

[0030] Acrylamide 20.000 g, 2-acrylamido-2-methylpropanesulfonic acid 6.300 g, 4-vinylbenzyl octylphenol polyoxyethylene ether (polyoxyethylene ether adduct EO is 20) 9.500 g Dissolve in 120 mL of distilled water, add it into a three-necked reaction flask, adjust the pH of the solution with NaOH = 7, the reaction temperature is 60 ℃, pass N 2 30min, add 5.20mL of 0.05mol / L potassium persulfate initiator solution, react for 32h, dilute the polymer with water to obtain a concentrated PAE solution. A certain amount of polymer PAE was taken to prepare a sample of oil-displacing agent aqueous solution, and the sample was colorless and transparent. The concentration of polymer is 2.2g / L, the concentration of oligophenolic resin is 0.75g / L, the concentration of sodium dodecylbenzenesulfonate is 0.2mmol / L, and the concentration of sodium sulfite is 0.05g / L. In the mixing container of the device, stir evenly at room temperature, and adjust the pH of the solution to be 5-10 to obtain a...

Embodiment 3

[0032] Dissolve 20.000 g of acrylamide, 5.100 g of 3-acrylimido-3-methylbutyric acid, and 7.000 g of allyl octylphenol polyoxyethylene ether (the adduct of polyoxyethylene ether EO is 12) 630mL of distilled water was added to the three-necked reaction flask, the pH of the solution was adjusted to 5 with NaOH, the reaction temperature was 60°C, and the N 2 30min, add 12.0mL of 0.05mol / L potassium persulfate initiator solution, react for 24h, dilute the polymer with water to obtain a concentrated PAE solution. A certain amount of polymer PAE was taken to prepare a sample of oil-displacing agent aqueous solution, and the sample was colorless and transparent. The polymer concentration is 1.2g / L, the total concentration of phenol and glutaraldehyde is 0.25g / L, the concentration of sodium dodecylbenzenesulfonate is 0.2mmol / L, and the concentration of sodium sulfite is 0.03g / L. In a mixing container with a stirring device, stir evenly at room temperature, and adjust the pH of the so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com