High-temperature-resistant gelled fracturing fluid, and preparation method and application thereof

A gel fracturing fluid and fracturing fluid technology, applied in chemical instruments and methods, earthwork drilling, mining fluids, etc., can solve the problems of general salt resistance and shear resistance, and achieve strong sand-carrying ability and cross-linking Simple, good jelly elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

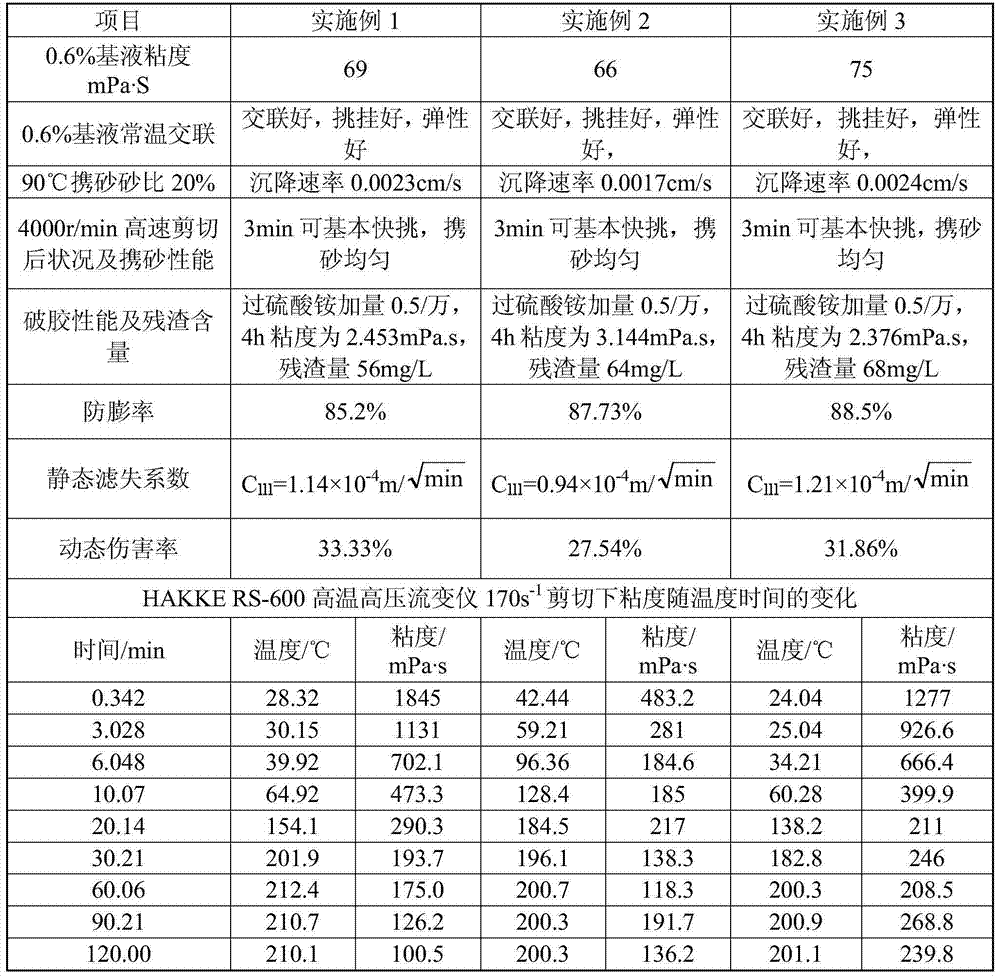

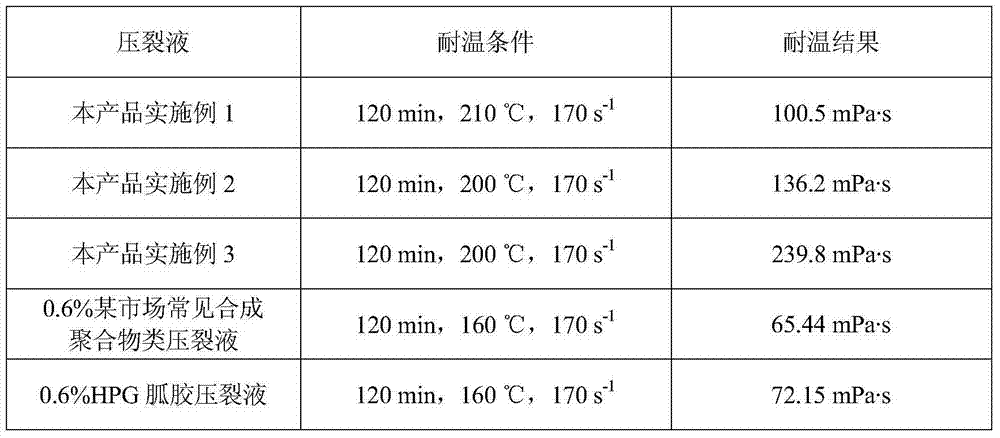

Embodiment 1

[0036] Add anionic polyacrylamide polymer in 98kg of water (this embodiment polymer thickener adopts 58.8kg of acrylamide, 24.5kg of 2-acrylamido-2-methyl propane sulfonic acid, methyl diallyl chloride Ternary polymerization of ammonium chloride 14.7kg, nitrogen deoxygenation, reaction temperature 10°C, reaction time 4h, molecular weight 461×10 4 ) 400g fully dissolved, add delayed cross-linking agent (the ratio of sodium gluconate, glycerol and water is mass ratio 25%:10%:65%) 50g, non-ionic surfactant (FACM-41) 0.5L , 50g of ammonium persulfate, then add 0.05L of 20% hydrochloric acid to adjust the pH of the system to 3-4, and configure it as a base solution. Add 1L of the cross-linking agent organic zirconium oxychloride solution into the base fluid and stir to form a jelly fracturing fluid. The gel forming time of the obtained jelly fracturing fluid is 1min. The jelly is transparent, has good elasticity, and has strong sand-carrying performance , the sand ratio is 20%, an...

Embodiment 2

[0038] Add anionic polyacrylamide polymers into 97.2kg of water (this embodiment uses acrylamide 68.04kg, 2-acrylamido-2-methylpropanesulfonic acid 14.58kg, methyldiallyl Ternary polymerization of ammonium chloride 14.58kg, deoxygenation by passing nitrogen gas, reaction temperature 25°C, reaction time 4h, molecular weight 450×10 4 ) 600g fully dissolved, add delayed cross-linking agent (the ratio of sodium gluconate, glycerol and water is mass ratio 25%:10%:65%) 70g, anionic surfactant (FACM-41) 0.65L, Ammonium persulfate 80g, then add 0.075L of 20% hydrochloric acid to adjust the pH of the system to 2, and configure it as a base solution. Add 1.35L of the cross-linking agent organic zirconium oxychloride solution into the base fluid and stir to form a jelly fracturing fluid. The gel forming time of the obtained jelly fracturing fluid is 45s. The jelly is transparent, has good elasticity, and has sand-carrying properties. Strong, the sand ratio is 20%, the temperature is 90 ...

Embodiment 3

[0040] Add anionic polyacrylamide polymer into 96.8kg of water (the polymer thickener in this example uses 67.76kg of acrylamide, 19.36kg of 2-acrylamido-2-methylpropanesulfonic acid, 19.36kg of methyldiallyl Ternary polymerization of ammonium chloride 9.68kg, nitrogen deoxygenation, reaction temperature 20°C, reaction time 4h, molecular weight 482×10 4 ) 700g fully dissolved, add delayed cross-linking agent (the ratio of sodium gluconate, glycerol and water is mass ratio 25%:10%:65%) 80g, anionic surfactant (FACM-41) 0.75L, Ammonium persulfate 90g, then add 0.085L of 20% hydrochloric acid to adjust the pH of the system to 2, and configure it as a base solution. Add 1.6L of the cross-linking agent organic zirconium oxychloride solution into the base fluid and stir to form a jelly fracturing fluid. The gel forming time of the obtained jelly fracturing fluid is 50s, and the jelly can be hung completely with a glass rod. When the sand ratio is 20% and the temperature is 90°C, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com