Nano silicon dioxide/polymer oil-displacing agent and synthesizing method thereof

A technology of nano-silica and synthesis method, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., and can solve the problems of reduced polymer viscosity adsorption and retention ability, reduced polymer fluidity control ability, and molecular chain damage. Achieve high viscosity, enhanced oil recovery, and strong shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: the preparation of nano silicon dioxide functional monomer

[0018] First, add 1.54g of nano-silica, 100ml of absolute ethanol, 17.22g of distilled water and 1.58ml of ammonia water with a mass concentration of 28% in a 250ml three-necked flask, and then disperse with ultrasonic wave for 30min; Add 0.22g of vinyltriethoxysilane dropwise; after the vinyltriethoxysilane is added dropwise, react in a water bath at a temperature of 30°C for 18h, centrifuge and dry to obtain a nano-silica functional monomer .

Embodiment 2

[0019] Embodiment 2: the synthesis of nano silica / polymer oil displacement agent

[0020] First add 0.05g of nano-silica functional monomer, 6.50g of acrylamide and 3.45g of acrylic acid into a 250ml three-necked flask, adjust the pH value to 7.0-7.5 with sodium hydroxide solution, and make the total mass concentration of monomers 20% Aqueous solution, nitrogen gas 45min; then add initiator ammonium persulfate solution and sodium bisulfite solution, the molar ratio of ammonium persulfate and sodium bisulfite is 1:1, and the amount of initiator added is 0.5% of the total mass of the monomer , continue to feed nitrogen, and react at a temperature of 45° C. for 8 hours; then wash with absolute ethanol, dry, and pulverize to obtain a terpolymer.

Embodiment 3

[0021] Embodiment 3: Characterization of nano silica / polymer oil displacement agent

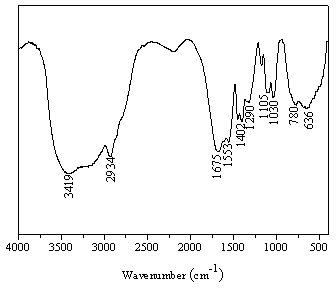

[0022] The infrared spectrogram of the nano silicon dioxide / polymer oil displacement agent synthesized by embodiment 2 is as follows figure 1 Shown, -C(O)NH 2 The stretching vibration peak of is located at 3419cm -1 , the stretching vibration peak of -C=O is located at 1675cm -1 , at 1105cm -1 The antisymmetric stretching vibration absorption peak of Si-O is at 780cm -1 is the bending vibration absorption peak of Si-O.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total salinity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com