Polyacrylamide inorganic nano composite drilling fluid aid and preparation method thereof

A polyacrylamide, composite technology, applied in chemical instruments and methods, drilling compositions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

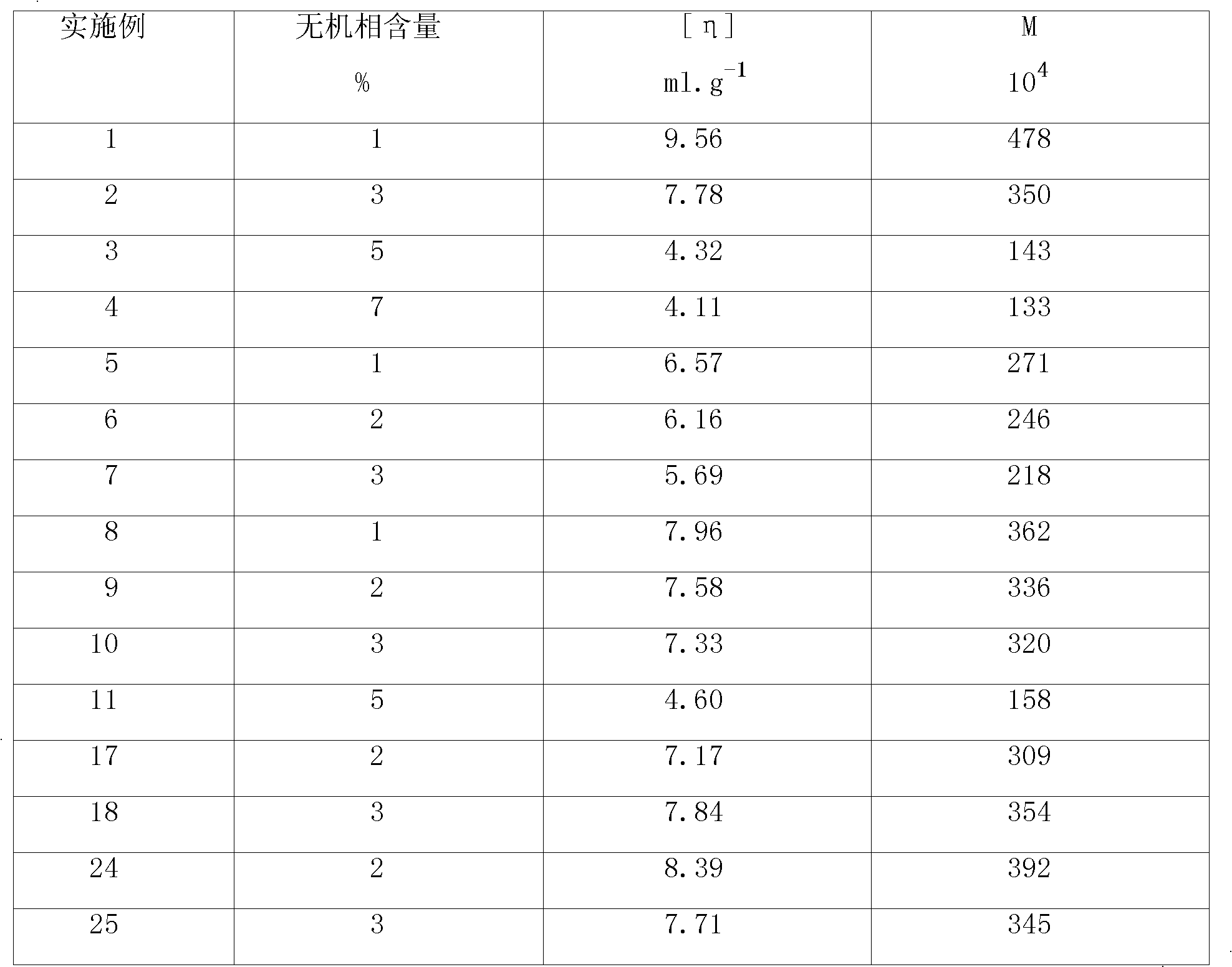

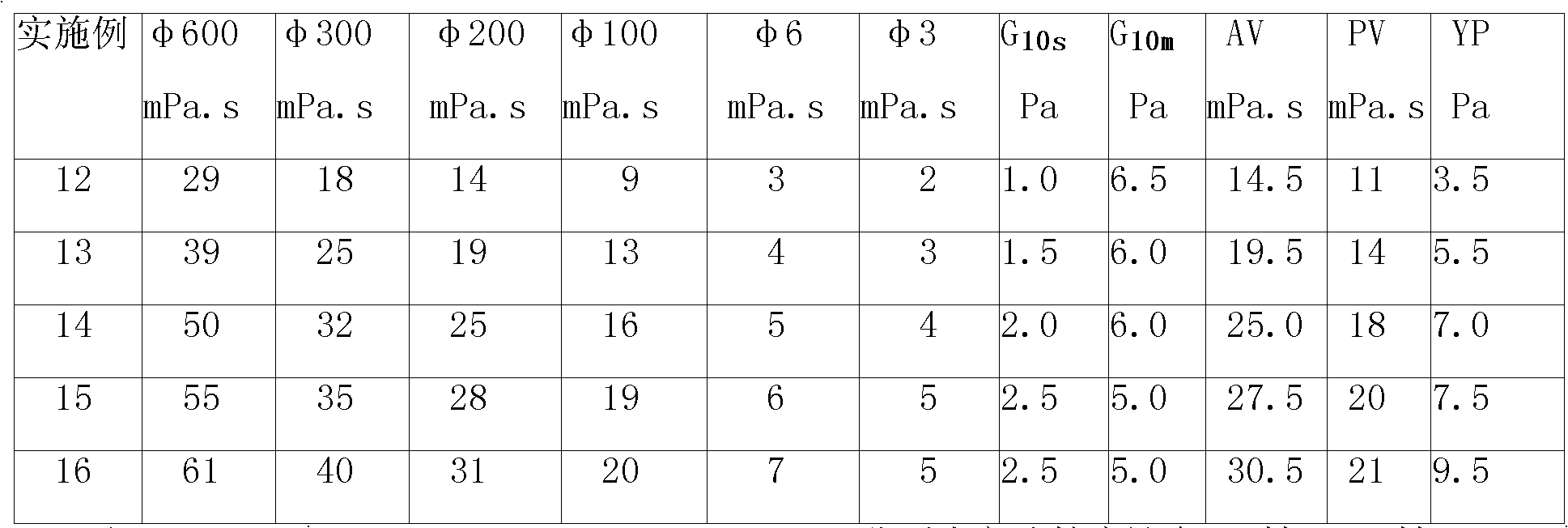

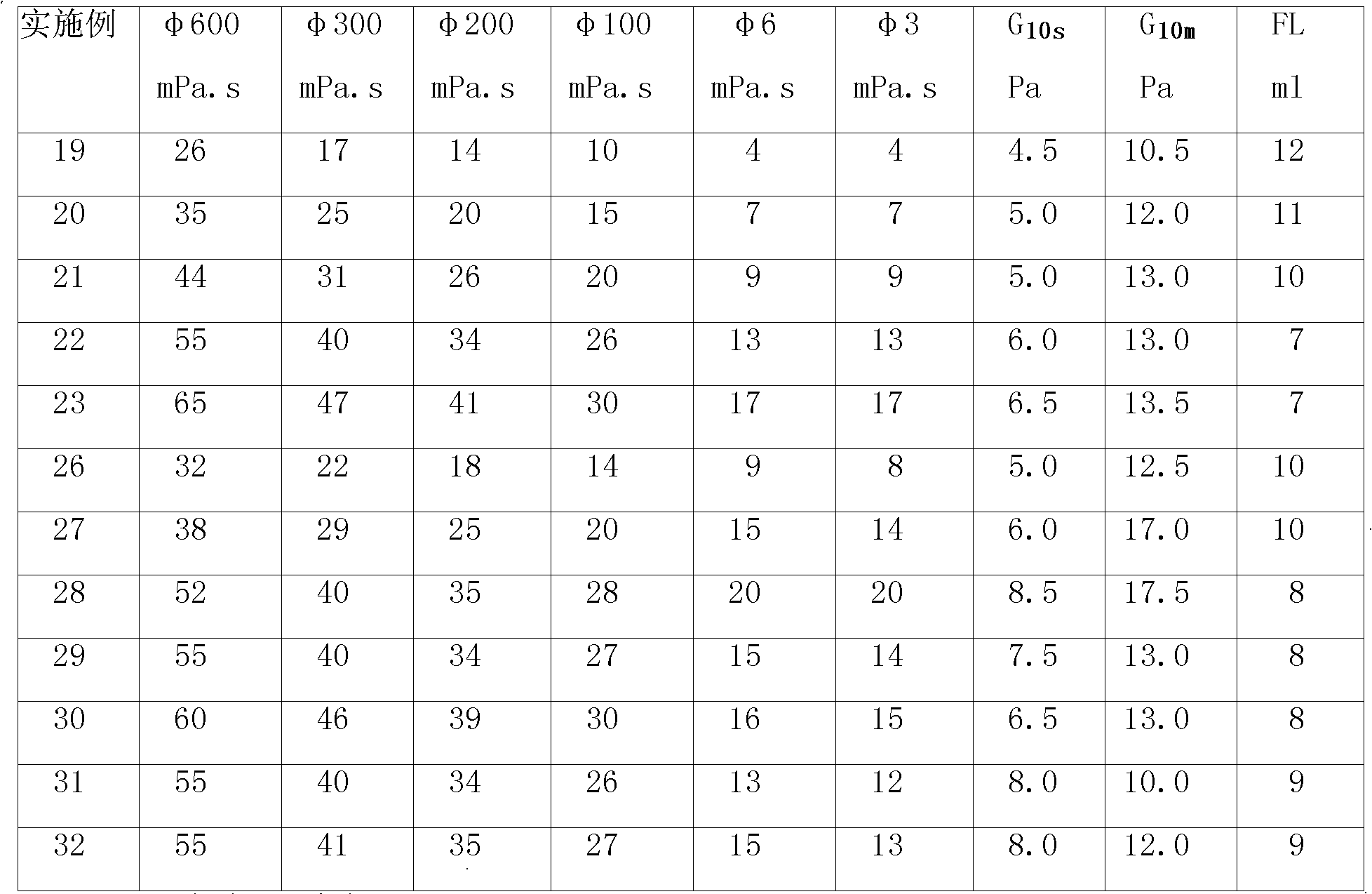

Examples

Embodiment 1

[0028] 0.08mol magnesium nitrate and 0.04mol aluminum nitrate were dissolved in 350ml distilled water. Dissolve 0.08mol sodium hydroxide and 0.08mol acrylic acid in 400ml distilled water, add nitrate solution dropwise at room temperature, adjust the pH value to about 10 with 3mol / L sodium hydroxide solution, and add 0.8g Coupling agent KH-151 was treated at 50°C for 5 hours to obtain inorganic phase suspension A

[0029] Add 50g of acrylamide and appropriate amount of water into the reactor to dissolve. Add 14wt% (acrylamide weight percentage, the same below) sodium carbonate, 6% sodium bicarbonate, 3% urea, 0.4% N,N'-tetramethylethylenediamine and appropriate amount of water to dissolve and stir evenly. Add the above-mentioned inorganic phase suspension A accounting for 1% of the mass of acrylamide monomer, stir and mix well, cool to about 10°C, add 0.2% ammonium persulfate and 0.2% sodium sulfite, and wait for the polymerization reaction to proceed until the temperature of ...

Embodiment 2

[0031] Add 50 g of acrylamide into the reactor, and add an appropriate amount of water to dissolve it. Add 14wt% (acrylamide weight percent, the same below) sodium carbonate, 6% sodium bicarbonate, 3% urea, 0.4% N,N'-tetramethylethylenediamine in sequence, add an appropriate amount of water to dissolve and stir evenly. Add the inorganic phase suspension A in Example 1 accounting for 3% of the mass of acrylamide monomer, stir and mix well, cool to about 10°C, add 0.2% ammonium persulfate and 0.2% sodium sulfite, wait for the polymerization reaction to proceed After the temperature of the system no longer rises, keep the temperature at 60°C for 2 hours, and hydrolyze at 100°C for 3 hours. Finally, the colloid was taken out and diced, dried at 85° C., and pulverized to obtain polyacrylamide nano-composite powder, and the size of the inorganic dispersed phase was 30-70 nm.

Embodiment 3

[0033]Add 50 g of acrylamide into the reactor, and add an appropriate amount of water to dissolve it. Add 14% (weight percentage based on acrylamide, the same below) sodium carbonate, 6% sodium bicarbonate, 3% urea, 0.4% N, N'-tetramethylethylenediamine in sequence, add appropriate amount of water to dissolve and stir uniform. Add the inorganic phase suspension A in Example 1 accounting for 5% of the mass of acrylamide monomer, stir and mix well, cool to about 10°C, add 0.2% ammonium persulfate and 0.2% sodium sulfite, wait for the polymerization reaction to proceed After the temperature of the system stops rising, keep the temperature at 60°C for 2 hours, and then hydrolyze at 100°C for 3 hours. Finally, the colloid was taken out and diced, dried at 85° C., and pulverized by a pulverizer to obtain a polyacrylamide nanocomposite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Gas permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com