Temperature and salt resistant copolymer for oil field and preparation method thereof

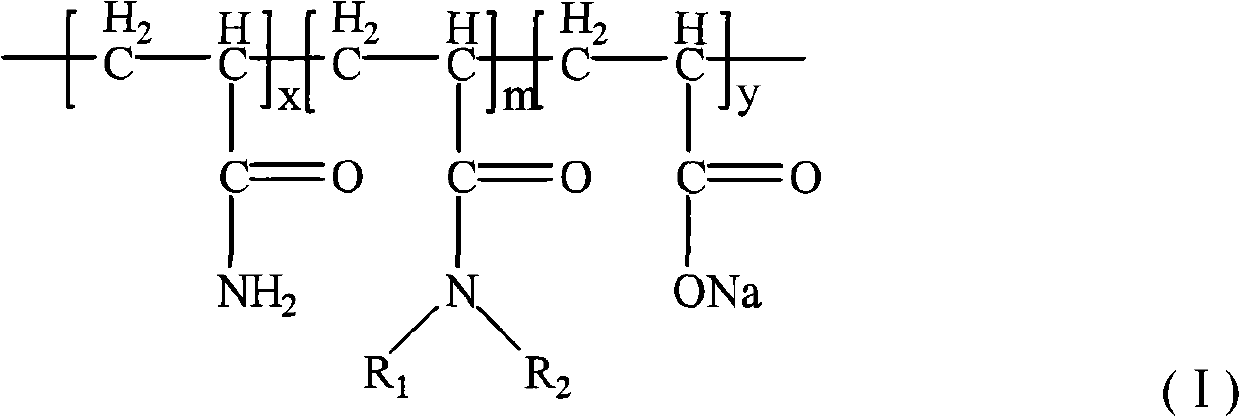

A temperature-resistant, salt-resistant, copolymer technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of easy hydrolysis of polyacrylamide, achieve improved hydrolysis stability, simple process flow, and increase crude oil recovery Yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

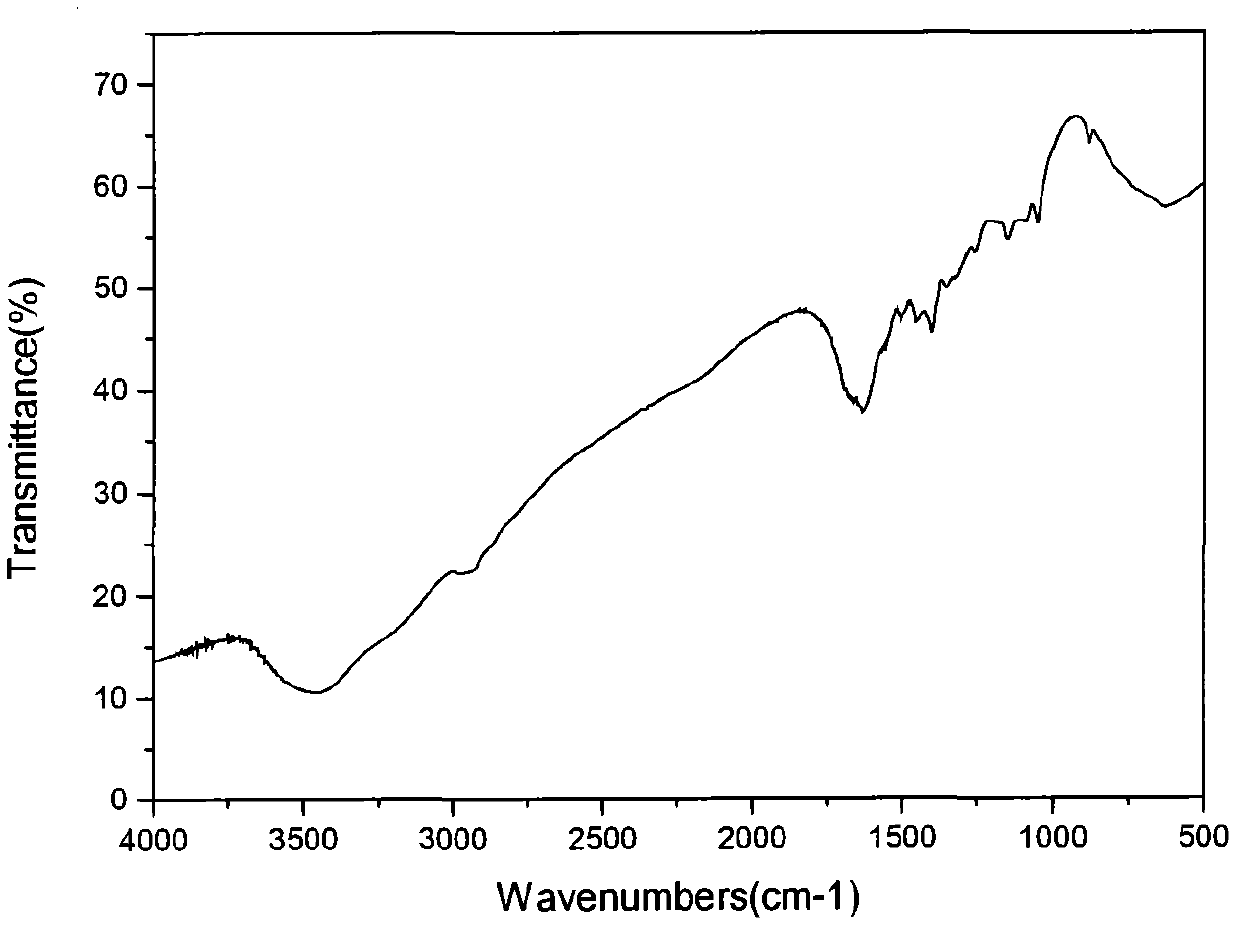

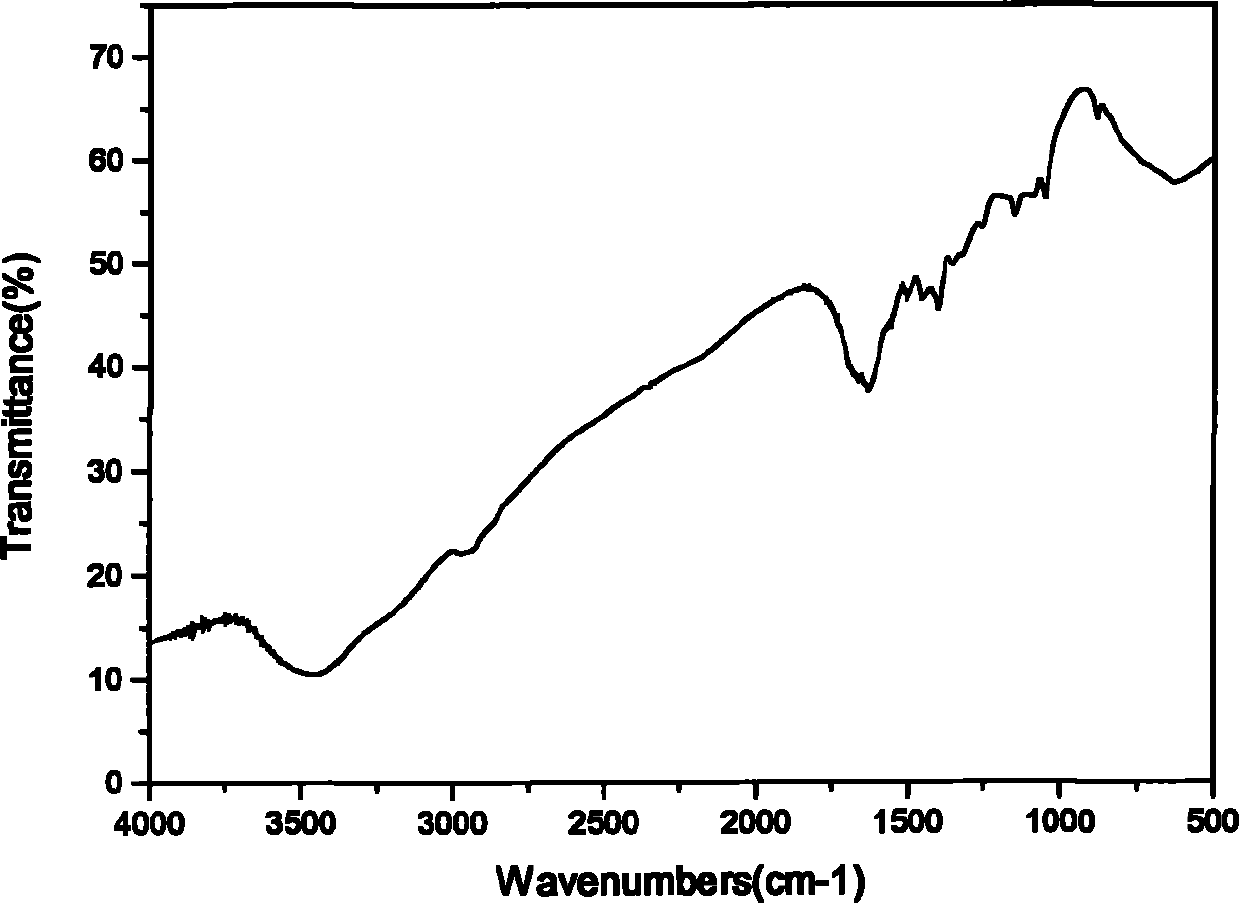

Embodiment 1

[0023] 69.3 parts of acrylamide and 5.7 parts of N,N-dimethylacrylamide were dissolved in 422 parts of water, so that the total mass fraction of the two monomers of acrylamide and N,N-dimethylacrylamide was 15%; Use 2 parts of sodium hydroxide solution to adjust the pH value to 8-10, pour the monomer solution into the reaction vessel, keep the water bath temperature at 5°C, and pass nitrogen gas to remove oxygen for 30 minutes; then add 0.003% composite initiator system: 0.15% super 0.23 parts of potassium sulfate solution, 0.13 parts of 0.09% sodium bisulfite solution, 0.3 parts of 0.6% N,N-dimethylaminoethyl methacrylate; after 30 minutes of reaction, the temperature was raised to 30°C, and the constant temperature polymerization was continued for 4 hours Afterwards, stop the reaction, add 157.6 g of 5% sodium hydroxide solution to the obtained colloidal product, and hydrolyze it for 1 hour at 80°C, then vacuum-dry and pulverize to obtain the temperature-resistant and salt-re...

Embodiment 2

[0025] 95 parts of acrylamide and 80 parts of N,N-diethylacrylamide were dissolved in 293 parts of water, so that the total mass fraction of the two monomers of acrylamide and N,N-diethylacrylamide was 35%; Use 2 parts of sodium hydroxide solution to adjust the pH value to 8-10, pour the monomer solution into the reaction vessel, keep the temperature of the water bath at 15°C, and pass nitrogen to deoxygenate for 30 minutes; then add 1.5% composite initiator system: 3.15% 12.5 parts of potassium persulfate solution, 12.5 parts of 15.75% sodium bisulfite solution, 5 parts of 5.25% N,N-dimethylaminoethyl methacrylate; after 60 minutes of reaction, the temperature was raised to 50°C, and the constant temperature polymerization was continued for 12 Hours later, stop the reaction, add 71.3 g of 15% sodium hydroxide solution to the obtained colloidal product, and hydrolyze it for 3 hours at 90 ° C, then vacuum-dry and pulverize to obtain the temperature-resistant and salt-resistant c...

Embodiment 3

[0027] 138.6 parts of acrylamide and 11.4 parts of N,N-dimethylacrylamide were dissolved in 340 parts of water, so that the total mass fraction of the two monomers of acrylamide and N,N-dimethylacrylamide was 30%; Use 2 parts of sodium hydroxide solution to adjust the pH value to 8-10, pour the monomer solution into the reaction vessel, keep the water bath temperature at 5°C, and pass nitrogen gas to remove oxygen for 30 minutes; then add 0.03% composite initiator system: 0.76% super 5 parts of potassium sulfate solution, 1 part of 0.23% sodium bisulfite solution, 1 part of 0.45% N,N-dimethylaminoethyl methacrylate; after 60 minutes of reaction, the temperature was raised to 30°C, and the constant temperature polymerization was continued for 12 hours Afterwards, stop the reaction, add 157.6 g of 10% sodium hydroxide solution to the obtained colloidal product, and hydrolyze it for 2 hours at 90 ° C, then vacuum-dry and pulverize to obtain the temperature-resistant and salt-resista...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Salinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com