High adhesion-promotion salt resistant water-soluble copolymer, preparation method and application thereof

A water-soluble copolymer and copolymer technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor anti-aging performance of polymer solutions, large hydrodynamic radius, and difficulties in meeting medium and low permeability oil layers Questions such as requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

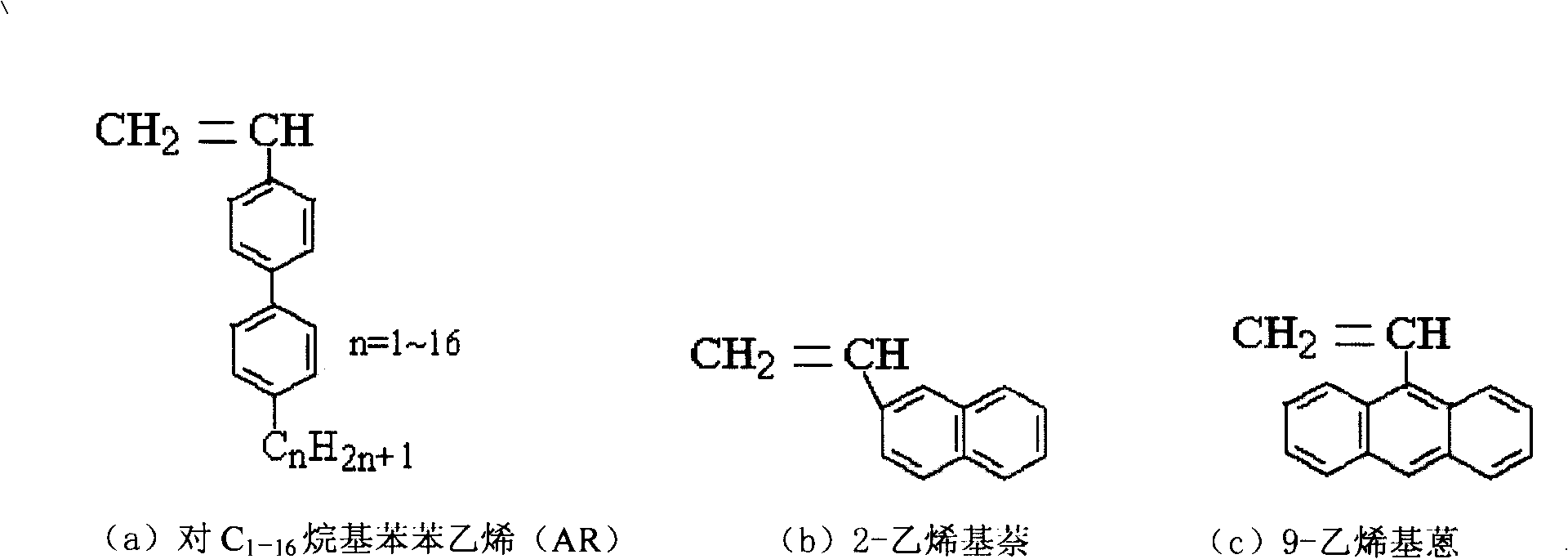

[0035] Dissolve 20.000 grams of acrylamide, 11.073 grams of acrylic acid, 3.070 grams of p-butylphenylstyrene and 72.502 grams of sodium lauryl sulfate in 875 ml of distilled water, add them to a three-necked reaction flask, adjust the pH of the solution to 8 with NaOH, and the reaction temperature is 50 ℃, through N 2 After 30 minutes, add 2.63 mL of 0.05 mol / L potassium persulfate initiator solution, react for 16 hours, and dilute the polymer with water to obtain a concentrated PAAM solution.

Embodiment 2

[0037] Dissolve 20.000 g of acrylamide, 0.500 g of 2-acrylamido-2-methylpropanesulfonic acid, 0.350 g of 2-vinylnaphthalene and 2.905 g of sodium lauryl sulfate in 78 ml of deionized water, and adjust the pH with NaOH =4, the reaction temperature is 50°C, and N is passed through 2 After 30 min, 1.55 mL of 0.05 mol / L ammonium persulfate initiator solution was added and reacted for 8 h. The polymer was dissolved in water to obtain a PAAM concentrated solution.

Embodiment 3

[0039] Dissolve 20.000 grams of acrylamide, 5.580 grams of dimethyl diallyl ammonium chloride, 0.270 grams of 9-vinyl anthracene and 7.200 grams of trimethylhexadecyl ammonium bromide in 220 ml of deionized water, and adjust with hydrochloric acid pH=7, reaction temperature 50°C, pass N 2 After 30 minutes, 3.40 mL of 0.05 mol / L potassium persulfate initiator solution was added and reacted for 24 hours. The polymer was dissolved in water to obtain a PAAM concentrated solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com