Association-type non-crosslinking fracturing fluid and preparation method thereof

A polymer and monomer solution technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of limited application range of fracturing fluid, not suitable for large-scale fracturing construction, difficult to control water loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Example 1 Synthesis of Water-Soluble Hydrophobic Association Polymer Fracturing Fluid Thickener—Copolymerization Method

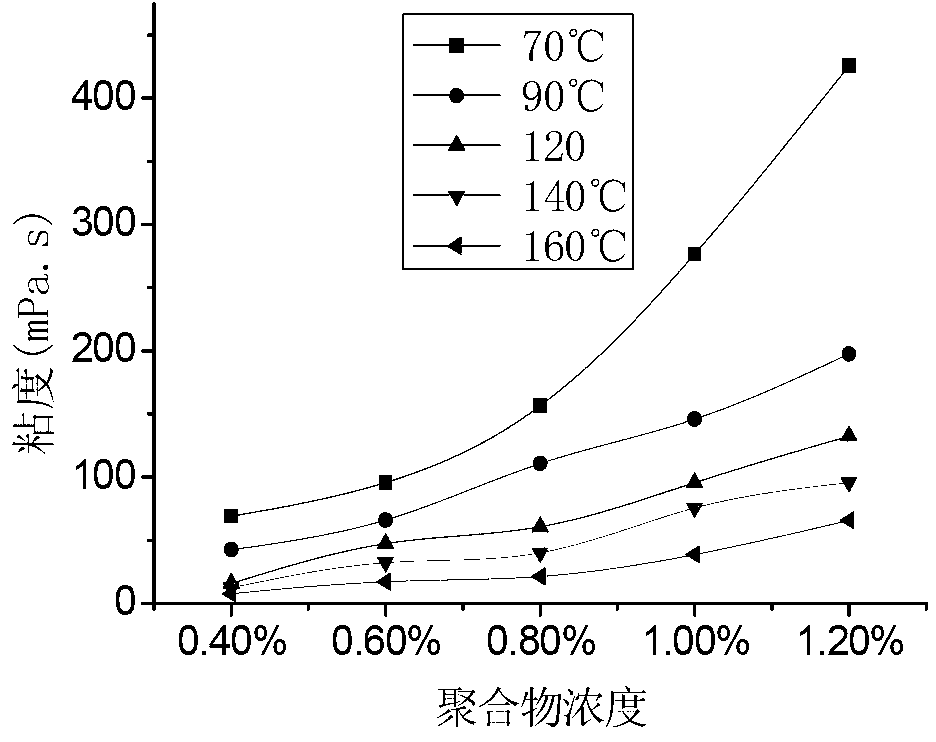

[0071] A water-soluble hydrophobic association polymer fracturing fluid thickener was prepared by copolymerization. See Table 1 for monomers, initiators, feed ratios of instant aids, water insolubles and viscosities under different temperature conditions.

[0072] Table 1 Associative thickener prepared by copolymerization

[0073]

[0074] Note: AM, NaAA, C12DMAAC, C14DMAAC, and C18DMAAC represent acrylamide, sodium acrylate, dodecyl dimethyl allyl ammonium chloride, tetradecyl dimethyl allyl ammonium chloride, octadecane respectively dimethyl allyl ammonium chloride.

[0075] In Table 1, the synthetic instant aid is composed of: sodium sulfate: urea: sodium formate: OP=2:1.5:0.25:0.25 (mass ratio), wherein OP is alkylphenol polyoxyethylene ether (OP-10).

[0076] In Table 1, the initiator I consists of: ammonium persulfate: sodium bisulfite = ...

Embodiment 2

[0091] Example 2 Synthesis of water-soluble hydrophobically associated polymer fracturing fluid thickener - hydrolysis after copolymerization

[0092] A water-soluble hydrophobically associated polymer fracturing fluid thickener was prepared by hydrolysis after copolymerization. See Table 3 for monomers, initiators, feed ratios of instant aids, water insolubles, and viscosities at different temperatures.

[0093] Table 3 Associative thickeners prepared by hydrolysis after copolymerization

[0094]

[0095] In Table 3, the composition of the synthetic instant aid is: sodium sulfate: urea: sodium formate: OP=2:1.5:0.25:0.25 (mass ratio).

[0096] In Table 3, the initiator I consists of: ammonium persulfate: sodium bisulfite = 1:1 (mass ratio).

[0097] In Table 3, the composition of initiator II is: ammonium persulfate: sodium bisulfite: V40=0.5:1:0.5 (mass ratio).

[0098] Mix all components in Table 3 except the initiator in a 2000mL beaker, pass high-purity nitrogen gas...

Embodiment 3

[0105] Example 3 Synthesis of Water-Soluble Hydrophobic Association Polymer Fracturing Fluid Thickener——Adiabatic Copolymerization and Cohydrolysis

[0106]Preparation of water-soluble hydrophobically associated polymer fracturing fluid thickener by adiabatic copolymerization and cohydrolysis. According to the feed ratio in Table 5, first add water (deionized water or reverse osmosis water) into a container with a stirred ceramic, stainless steel or glass inner wall, and then add NaOH, because a lot of heat will be generated when the alkali dissolves, so pay attention to the speed of adding NaOH not too fast. Then add AM, C12DMAAC (or C14DMAAC, C18DMAAC), AMPS (if any) instant aids in turn to stir the above components evenly, then control the temperature of the material to 25°C, and transfer it to a thermally insulated container with a ceramic inner wall with a temperature detector , Nitrogen flow for 15 minutes, add initiator, continue nitrogen flow for 15 minutes, stop nitr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com