Titania coating kaolinite compound powder and method for preparing same

A composite powder and kaolin technology, applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve the problems of weak binding force between titanium oxide and kaolin, large final powder particles, etc., and achieve a small particle size distribution range. , The effect of uniform whiteness and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

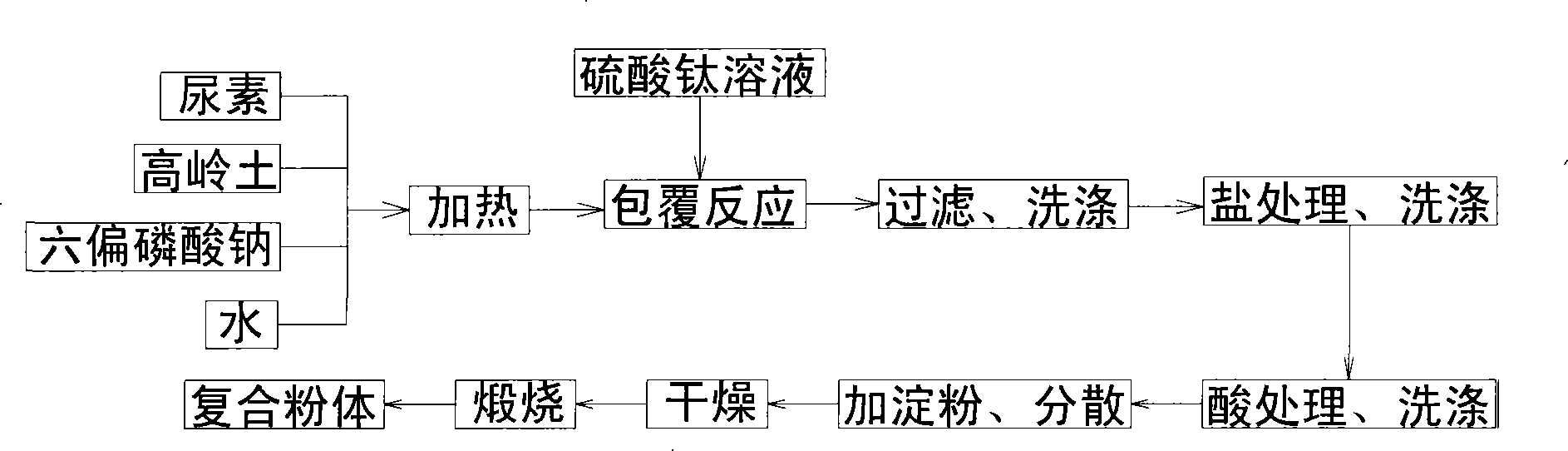

[0040] Example 1: A preparation method of titanium oxide-coated kaolin composite powder

[0041] According to attached figure 1 Shown preparation method flowchart, the raw material formula that adopts is made up of following composition:

[0042] Titanium sulfate: 17Kg;

[0043] Kaolin: 8Kg;

[0044] Urea: 15Kg;

[0045] Sodium hexametaphosphate: 0.25Kg;

[0046] Starch: 1.1Kg;

[0047] Potassium carbonate: 0.07Kg;

[0048] Phosphoric acid: 0.04Kg;

[0049] Water: 58.5Kg.

[0050](1) Coating reaction: Add kaolin, urea, sodium hexametaphosphate and water into the reaction vessel, stir and mix evenly, and then heat it, during which a small amount of bubbles are generated. When the solution is heated to 70°C to 90°C, evenly add the titanium sulfate solution, and stir well, so that the metatitanic acid precipitate generated by the titanium sulfate evenly covers the surface of the kaolin. The titanium sulfate solution must be heated to 70°C to 90°C to avoid hydrolysis reac...

Embodiment 2

[0065] Example 2: A preparation method of titanium oxide-coated kaolin composite powder

[0066] According to attached figure 1 Shown preparation method flowchart, the raw material formula that adopts is made up of following composition:

[0067] Titanium sulfate: 13Kg;

[0068] Kaolin: 7Kg;

[0069] Urea: 11Kg;

[0070] Sodium hexametaphosphate: 0.17Kg;

[0071] Starch: 0.55Kg;

[0072] Sodium carbonate: 0.04Kg;

[0073] Phosphoric acid: 0.015Kg;

[0074] Water: 68.2Kg.

[0075] The preparation method is the same as in Example 1.

Embodiment 3

[0076] Example 3: A preparation method of titanium oxide-coated kaolin composite powder

[0077] According to attached figure 1 Shown preparation method flowchart, the raw material formula that adopts is made up of following composition:

[0078] Titanium sulfate: 15Kg;

[0079] Kaolin: 7Kg;

[0080] Urea: 13Kg;

[0081] Sodium hexametaphosphate: 0.2Kg;

[0082] Starch: 0.9Kg;

[0083] Ammonium carbonate: 0.06Kg;

[0084] Phosphoric acid: 0.03Kg;

[0085] Water: 63.8Kg.

[0086] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com