Spherical porous high-density LiFePO4 powder and process for preparing same

A high-density, PO43- technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of increased production costs, long holding time, high roasting temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

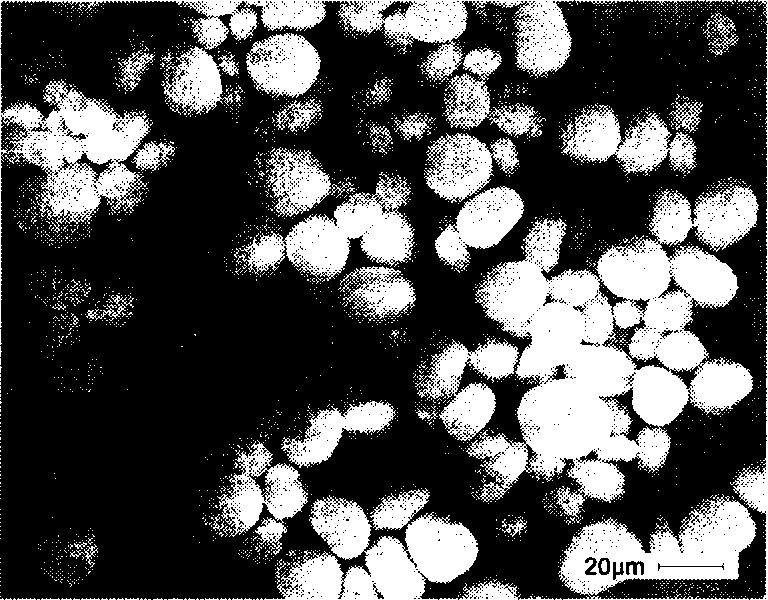

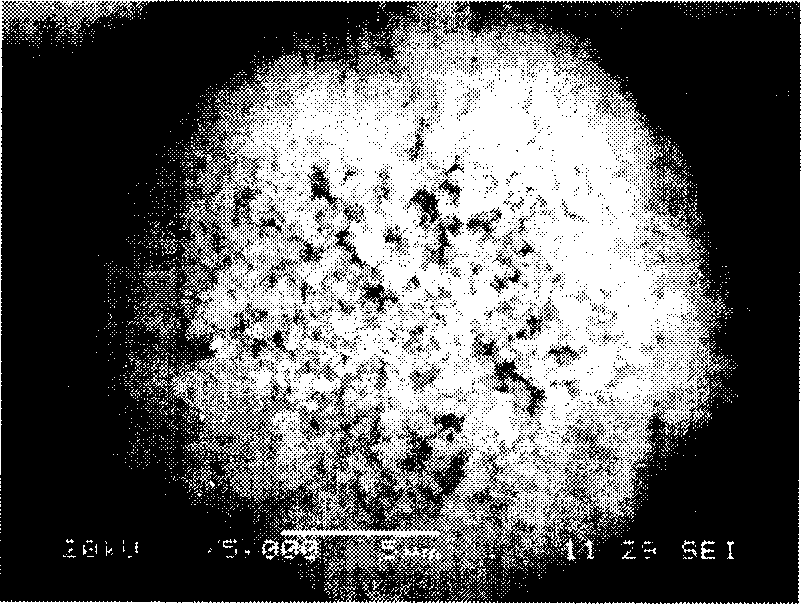

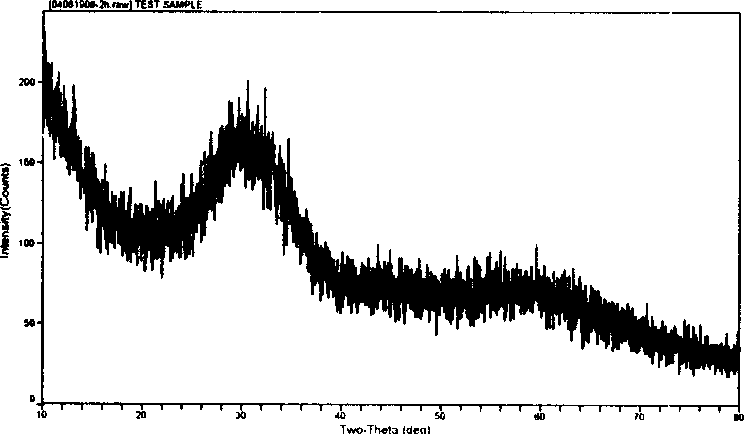

[0045] Press Fe 2+ :PO 4 3- Mix the ferrous sulfate solution and the ammonium phosphate solution at a molar ratio of 3:2, adjust the pH value of the mixed solution to 7.0 with ammonia water, and mechanically stir for 40 hours to form a ferrous phosphate precipitate; wash the obtained ferrous phosphate precipitate with water for 3 to 5 times , filtered, vacuum-dried at 60°C and kept warm for 20 hours to obtain a spherical porous structure amorphous ferrous phosphate hydrate powder with a particle size of 1 to 25 μm; the obtained spherical porous structure amorphous ferrous phosphate hydrate powder was placed in a Ionized water, add lithium hydroxide and phosphoric acid solution to it, and make Li + : Fe 2+ :PO 4 3- The molar ratio is 1:1:1, electromagnetic stirring for 3 hours, and filtration to obtain the precursor powder of lithium phosphate-wrapped amorphous ferrous phosphate; the precursor powder is placed in an inert gas roasting tube furnace, and nitrogen is introduc...

Embodiment 2

[0047] Prepare ferrous sulfate solution of 1.10mol / L and ammonium dihydrogen phosphate solution of 0.73mol / L, adjust the flow rate of the metering pump to 8ml / min, input the equal flow rate of the above solution into the reactor filled with 4L water in advance, pass NaOH controls the pH value of the reaction solution at 4.5, the mother liquor flows into the discharge barrel from the overflow, the electromagnetic stirring continues the reaction for 10h, and the feeding is stopped. The liquid in the discharge barrel is washed with water several times, then filtered, placed in vacuum drying at 80° C. for 5 hours, and ground to obtain spherical porous ferrous phosphate hydrate powder with a particle size of 2-30 μm. Spherical porous structure hydrated ferrous phosphate powder is placed in deionized water, lithium hydroxide and phosphoric acid solution are added thereto, and Li + : Fe 2+ :PO 4 3- The molar ratio is 1:1:1, after 15 hours of mechanical stirring, sucrose is added t...

Embodiment 3

[0049] Prepare 0.42mol / L ferrous sulfate solution and 0.28mol / L ammonium phosphate solution, adjust the flow rate of the metering pump to 10ml / min, input the equal flow rate of the above solution into the reactor filled with 4L water in advance, and control it with ammonia water The pH value of the reaction solution was 6.5, and the mother liquor flowed into the discharge barrel from the overflow, and the reaction was continued for 30 hours, and the feeding was stopped. The liquid in the discharge barrel is washed with water several times, then filtered, placed in vacuum drying at 70° C. for 10 hours, and spherical porous ferrous phosphate hydrate powder with a particle size of 1-25 μm is obtained. Spherical porous structure hydrated ferrous phosphate powder is placed in deionized water, lithium hydroxide and phosphoric acid solution are added to it, and Li + : Fe 2+ :PO 4 3- The molar ratio was 1:1:1, electromagnetic stirring was performed for 8 hours, and rotary evaporati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com