Method for preparing MXene quantum dot by etching with alkali liquor

A technology of quantum dots and lye, which is applied in the field of MXene quantum dots prepared by lye etching, can solve problems such as environmental and human hazards, and the performance of quantum dots is greatly affected, and achieves the advantages of increased concentration, easy control of reaction conditions, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

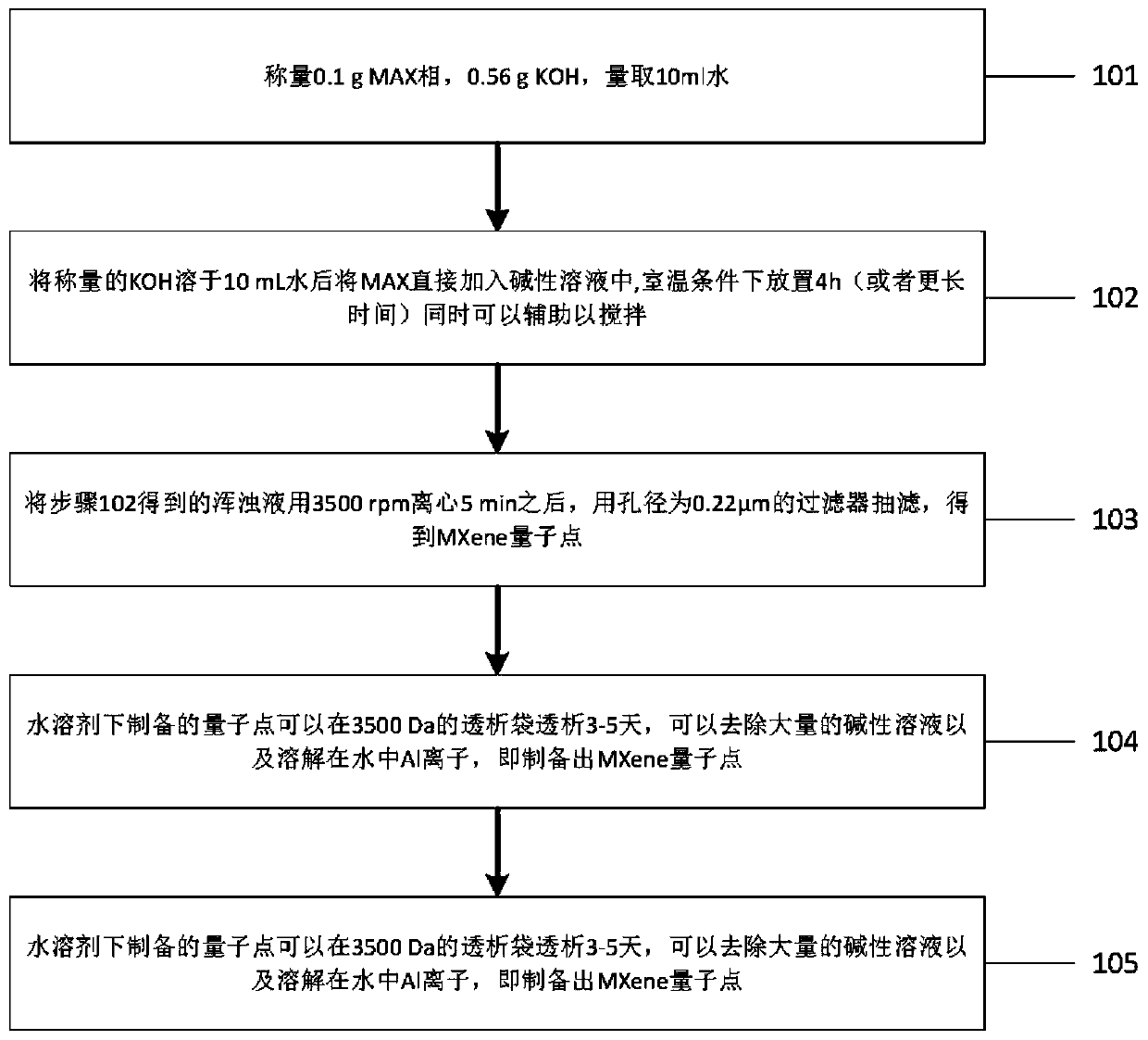

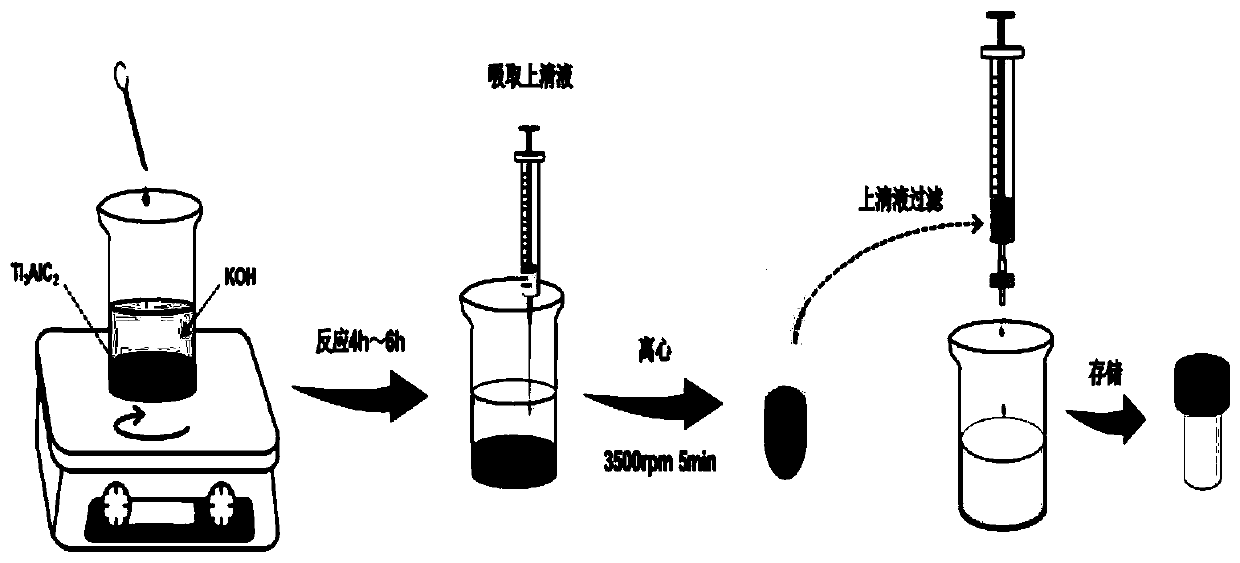

[0035] Such as Figure 1-2 Shown, according to the preparation method of MXene quantum dot of the present invention, described method step is as follows:

[0036] Step 101. Weigh 0.1g MAX phase, 0.56g KOH, measure 10ml water.

[0037] Step 102. Dissolve the weighed KOH in 10 mL of water, then directly add MAX to the alkaline solution, and place it at room temperature for 4 hours (or longer) while stirring.

[0038] Step 103. Centrifuge the turbid solution obtained in step 102 at 3500 rpm for 5 min, and then filter it with a filter with a pore size of 0.22 μm to obtain MXene quantum dots.

[0039] Step 104. The quantum dots prepared under the water solvent can be dialyzed in a 3500Da dialysis bag for 3-5 days, which can remove a large amount of alkaline solution and Al ions dissolved in water, that is, prepare MXene quantum dots;

[0040] Step 105. By replacing the ionized water with the organic solvent DMSO and mixing and stirring with the MAX phase at 90°C for 1 hour, high-...

Embodiment approach 1

[0043] Weigh 0.1g Ti 3 AlC 2 , 0.56g KOH, KOH was dissolved in 10mL deionized water (made into 1mol alkaline solution), the glass beaker was sealed with plastic wrap, placed at room temperature for 6h and assisted by magnetic stirring, and the resulting turbid solution was centrifuged at 3500rpm for 5min , take the supernatant, and filter it with a filter membrane with a pore size of 0.22 μm to obtain a light yellow clear solution. The obtained solution was dialyzed with a dialysis bag (3500Da) for 3 days to remove alkaline ions and metal ions in the solution to obtain Ti 3 C 2 quantum dots. (Replace KOH with other medium-strong alkali solutions, repeat the above steps to obtain the same light yellow clear solution.)

[0044] The prepared quantum dots were tested as follows:

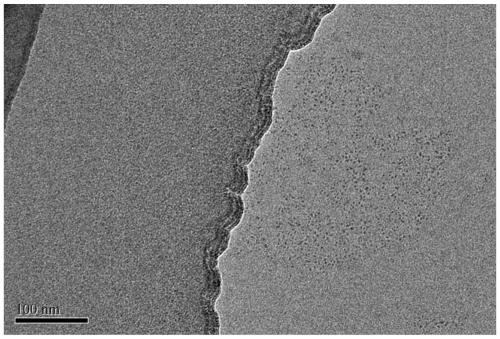

[0045] Characterized by high-resolution transmission electron microscopy, from Figure 3-4 It can be seen from the high-resolution transmission electron microscope image that the prepared quantum d...

Embodiment approach 2

[0047] Weigh 0.2g Ti 3 AlC 2 , 0.56g KOH, dissolving KOH in 10ml of DMSO and heating to 90°C to make it dissolve (make a 1mol / L alkaline solution), seal the glass beaker with plastic wrap, place it at room temperature for 6h and assist with stirring, put After the obtained turbid solution was centrifuged at 3500 rpm for 5 min, the supernatant was taken to obtain a dark brown clear solution. (Replace DMSO with other organic solvents and repeat the above process to obtain a similar dark solution.) After centrifuging the prepared solution, go to the upper layer and put the homogeneous solution into a glass bottle. Use a laser pointer to find the Tyndall phenomenon, indicating that a uniform colloidal solution is formed. , see Figure 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com