Preparation and application methods of nanometer carbon sphere-supported MXene composite material

A technology of nano-carbon spheres and composite materials, which is applied in the direction of nano-carbon, electrical components, electrochemical generators, etc., to achieve the effects of simple process methods, solving stacking and agglomeration, and increasing ion transmission channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] MXene Ti supported by carbon nanospheres 3 C 2 The preparation of composite material comprises the following steps:

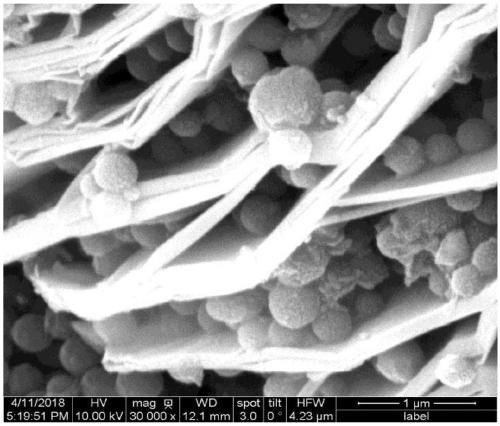

[0022] (1) 1g Ti with a particle size of 500 mesh 3 AlC 2 The powder is submerged in 20mL of 6mol / L mixed solution of sodium fluoride and hydrochloric acid, stirred at 60°C for 24h, cooled to room temperature, then poured into a centrifuge tube and centrifuged several times with deionized water until the solution in the centrifuge tube It was neutral, and the upper layer solution was precipitated. The sample left at the bottom of the centrifuge tube was dried in a vacuum oven at 80°C for 12 hours to obtain a two-dimensional crystal compound MXene Ti 3 C 2 ,From figure 1 It can be clearly seen that after being etched by the mixed solution of sodium fluoride and hydrochloric acid, it presents a lamellar shape with an obvious lamellar structure and a thickness of about 50nm.

[0023] (2) Mix and dissolve a certain amount of glucose and deionized water...

Embodiment 2

[0029] MXene Ti supported by carbon nanospheres 2 The preparation of C composite material and its magnesium battery performance comprise the following steps:

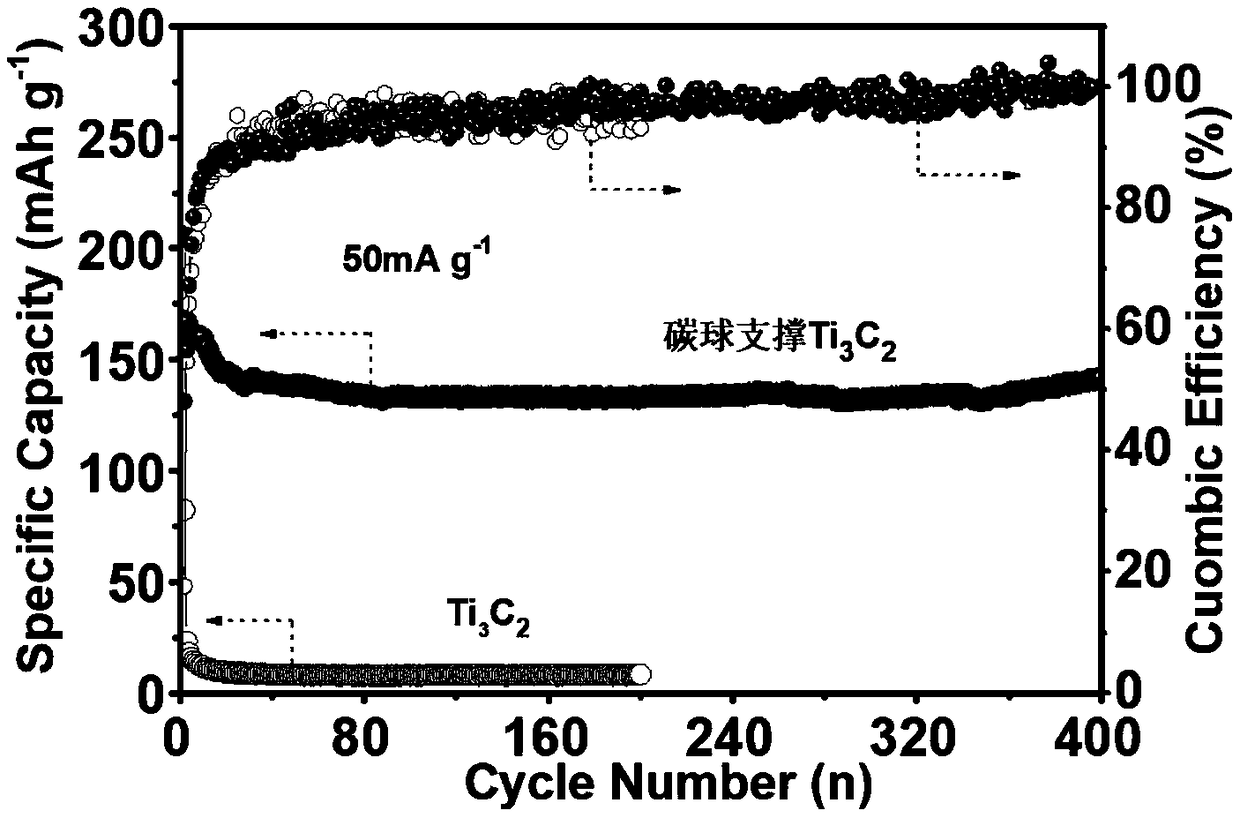

[0030] 1g Ti with a particle size of 500 mesh 2 Submerge the AlC powder in 20mL of 6mol / L mixed solution of sodium fluoride and hydrochloric acid, stir at 40°C for 48h, cool to room temperature, pour it into a centrifuge tube and wash it by centrifugation until the solution is neutral, and the upper layer solution is precipitated, leaving the bottom of the centrifuge tube The sample below was dried in a vacuum oven at 80°C for 12 hours to obtain a two-dimensional crystal compound Ti 2 C powder. The preparation of carbon nanospheres is as described in Example 1. Ti 2 C powder is made nanometer carbon sphere supports MXene Ti according to the method for embodiment 1 2 C composite material, made into electrode, assembled into a magnesium ion battery, the discharge capacity after 400 cycles at a current density of 50mA...

Embodiment 3

[0032] MXene V supported by carbon nanospheres 2 The preparation of C composite material and its magnesium battery performance comprise the following steps:

[0033] The particle size is 500 mesh 1g V 2 Submerge the AlC powder in 20mL of 6mol / L mixed solution of sodium fluoride and hydrochloric acid, stir at 90°C for 72h, cool to room temperature, pour it into a centrifuge tube and wash it by centrifugation until the solution is neutral, and the upper layer solution is precipitated, leaving the bottom of the centrifuge tube The sample below was placed in a vacuum drying oven at 80°C for 12 hours to obtain a two-dimensional crystal compound V 2 C powder. The preparation of carbon nanospheres is as described in Example 1. With the prepared V 2 C powder is made into nano-carbon spheres to support MXene V according to the method of Example 1 2 C composite material, made into electrode, assembled into a magnesium ion battery, the discharge capacity after 200 cycles at a curren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com