FeCo/MXene compound, and preparation method and application thereof

A compound and sediment technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve problems such as high overpotential, poor durability, scarce supply, etc., and achieve simple, safe and good operation Catalytic effect, effect of cheap material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

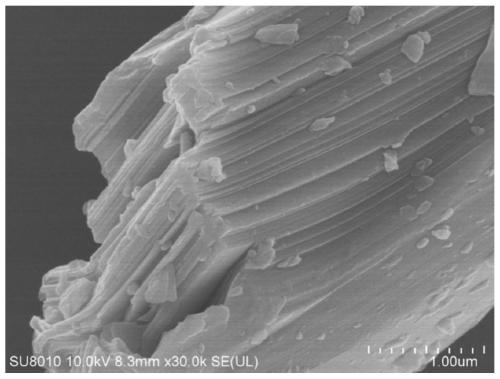

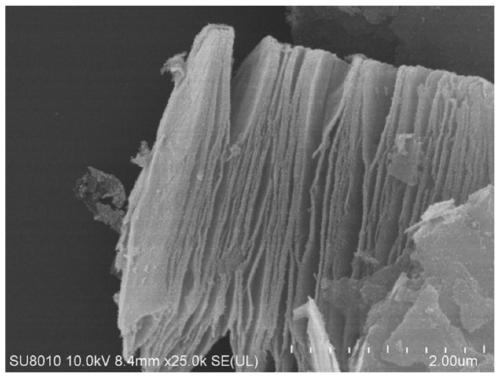

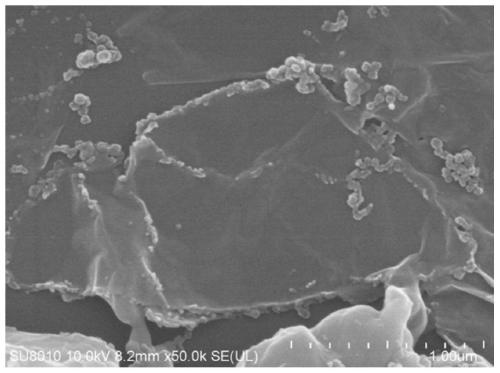

[0031] (1) FeCo / MXene composite (FeCo / Ti 3 C 2 ) preparation

[0032] Including the following steps:

[0033] 1. MXene (Ti 3 C 2 ) preparation:

[0034] 1) Weigh 2g Ti in a 50mL centrifuge tube 3 AlC 2 , slowly added 30 mL of 40% HF, stirred at room temperature for 48 h, centrifuged the obtained reaction solution (3500 rpm, 10 min), and discarded the supernatant. Add 40 mL of deionized water to the sediment in the centrifuge tube, shake it by hand to mix the sediment and deionized water evenly, put the centrifuge tube into a high-power ultrasonic machine for ultrasonic dispersion (750W, 10min), take it out and continue centrifuging (3500rpm, 10min) discard the supernatant, repeat several times, until the pH value of the supernatant poured out after centrifugation is above 5, preferably, the pH value is 5-7, and the final precipitate is obtained.

[0035] 2) Add 40 mL of ethanol to the final precipitate in the centrifuge tube obtained in step 1), ultrasonically disperse...

Embodiment 2

[0048] Effect of Coating Different Compounds on Electrocatalytic Anodic Water Oxidation

[0049] (1) Preparation of catalyst

[0050] 1. The present invention - FeCo / Ti 3 C 2 Composite: get the product prepared in Example 1

[0051] 2. Comparative example - FeCo composite: Weigh 0.1212g Fe(NO 3 ) 3 9H 2 O, 0.0873gCo(NO 3 ) 2 ·6H 2 O and 1.8g urea, add 2mL of deionized, ultrasonically dissolved, pour into a Shleck bottle, under the protection of nitrogen, heat and stir at 100°C for 5h; put the obtained reactant into a centrifuge tube, centrifuge (10000 rpm, 10min) three times, and water Wash repeatedly. Put it into a freeze dryer to freeze to obtain a powdery substance, which is FeCo hydroxide compound.

[0052] (2) Electrode preparation

[0053] Take 4mg FeCo / Ti respectively 3 C 2 Composite powder, few layers of Ti 3 C 2 Add 485 μl of deionized water, 500 μl of absolute ethanol and 10 μl of Nafion to the powder and FeCo hydroxide complex, respectively, ultrasoni...

Embodiment 3

[0058] Different Fe(NO 3 ) 3 9H 2 O and Co(NO 3 ) 2 ·6H 2 The effect of the molar ratio of O species on electrocatalytic anodic water oxidation (1) Catalyst preparation

[0059] 1. Few layers of Ti 3 C 2 The preparation of powder: with embodiment 1.

[0060] 2. FeCo / Ti 3 C 2 Preparation of complex

[0061] 1) Weigh 5mg of few-layer Ti 3 C 2 powder, add 500 μL of deionized water, after ultrasonic dispersion, add 2 mL of N-methylpyrrolidone as a stabilizer, continue ultrasonic dispersion, and obtain few layers of Ti 3 C 2 Dispersions.

[0062] 2) Weigh Fe(NO 3 ) 3 9H 2 O and Co(NO 3 ) 2 ·6H 2 O and 1.8g urea, add 2mL deionized, ultrasonically dissolved.

[0063] Table 1

[0064] ratio of substances

1:2

1:3

2:1

3:1

1:1

Fe(NO 3 ) 3 .9H 2 o / g

0.1212

0.1212

0.2424

0.3636

0.1212

Co(NO 3 ) 2 .6H 2 o / g

0.1746

0.2619

0.0873

0.0873

0.0873

[0065] 3) Mix the solution obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com