Two-dimensional metal carbonitride derived nano-material and preparation method therefor

A technology of metal carbonitrides and nanomaterials, applied in chemical instruments and methods, titanium compounds, alkali metal titanates, etc., can solve the problems of easy deterioration, easy stacking and agglomeration, and achieve non-deterioration, high reactivity, and specific The effect of high surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 2g Ti 3 AlC 2 Shake reaction with 200mL 40% hydrofluoric acid for 72h, centrifuge and wash with high-purity water, and vacuum-dry at 60°C for 24h to obtain accordion-shaped Ti 3 C 2 . 0.1g accordion-shaped Ti 3 C 2 with 0.67mL H 2 o 2 30mL of 1mol / L NaOH solution was mixed evenly, placed in a 50mL hydrothermal kettle, and treated at 140°C for 12h to obtain ultra-thin sodium titanate nanobelts.

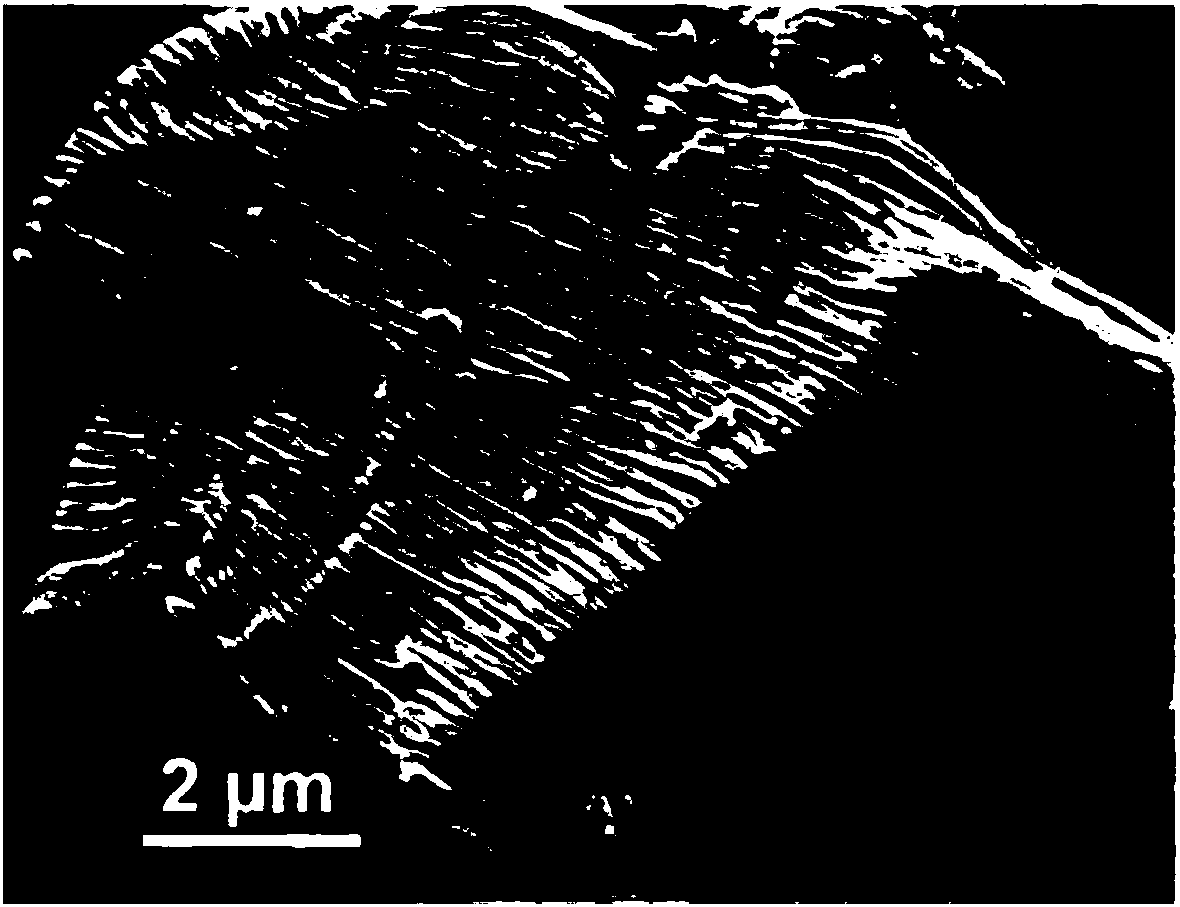

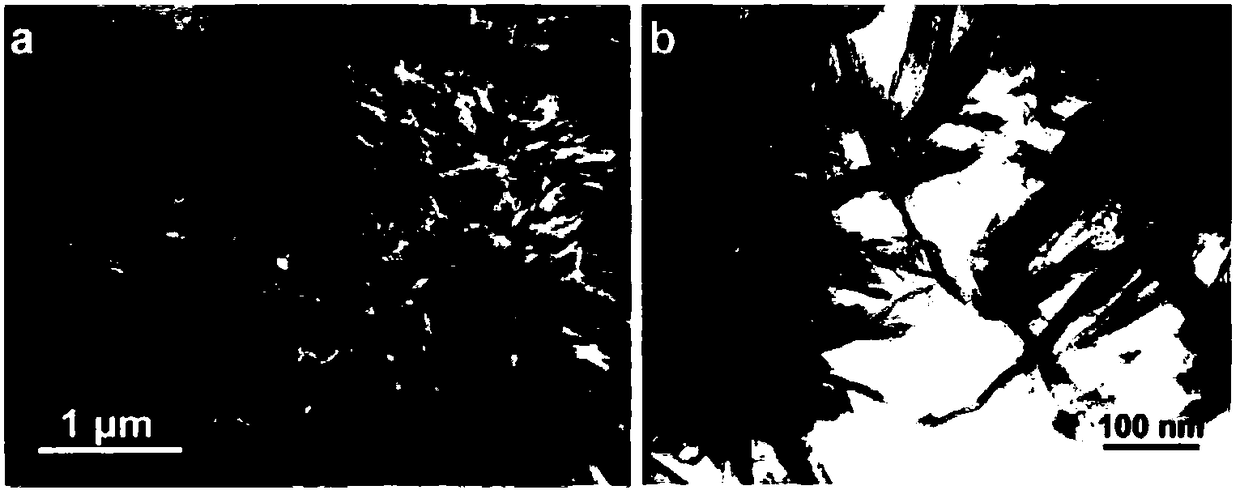

[0035] The resulting accordion-shaped Ti 3 C 2 The scanning electron micrographs of the sodium titanate nanoribbons are as follows figure 1 , figure 2 As shown in a, the transmission electron microscope image of sodium titanate nanoribbons is as follows figure 2 as shown in b. from figure 1 and figure 2 It can be seen that through NaOH and H 2 o 2 Solution-processed, accordion-shaped Ti 3 C 2 It becomes a sea urchin-shaped microsphere assembled by nanoribbons, and the nanoribbons have the structural characteristics of thin thickness and narrow width.

Embodiment 2

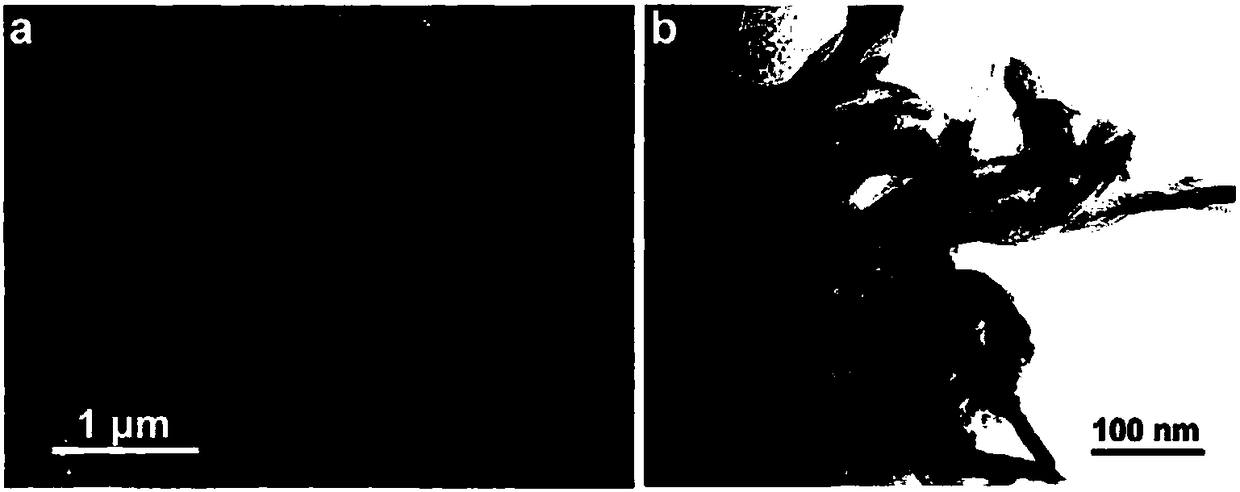

[0037] 2g Ti 3 AlC 2Shake reaction with 200mL 40% hydrofluoric acid for 72h, centrifuge and wash with high-purity water, and vacuum-dry at 60°C for 24h to obtain accordion-shaped Ti 3 C 2 . 0.1g accordion-shaped Ti 3 C 2 with 0.67mL H 2 o 2 30mL of 1mol / L KOH solution was mixed evenly, placed in a 50mL hydrothermal kettle, and treated at 140°C for 12h to obtain ultra-thin potassium titanate nanobelts. Depend on image 3 Electron microscope photos show that, through KOH and H 2 o 2 Solution-processed, accordion-shaped Ti 3 C 2 It becomes a potassium titanate nanoribbon network structure.

Embodiment 3

[0039] 2g Ti 3 AlC 2 Shake reaction with 200mL 40% hydrofluoric acid for 72h, centrifuge and wash with high-purity water, and vacuum-dry at 60°C for 24h to obtain accordion-shaped Ti 3 C 2 . 0.1g accordion-shaped Ti 3 C 2 with 0.67mL H 2 o 2 30mL of 5mol / L NaOH solution was mixed uniformly, placed in a 50mL hydrothermal kettle, and treated at 140°C for 12h to obtain sodium titanate nanowires ( Figure 4 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com