In-situ water electret method based on electrostatic spinning and fiber material with charge bubbles

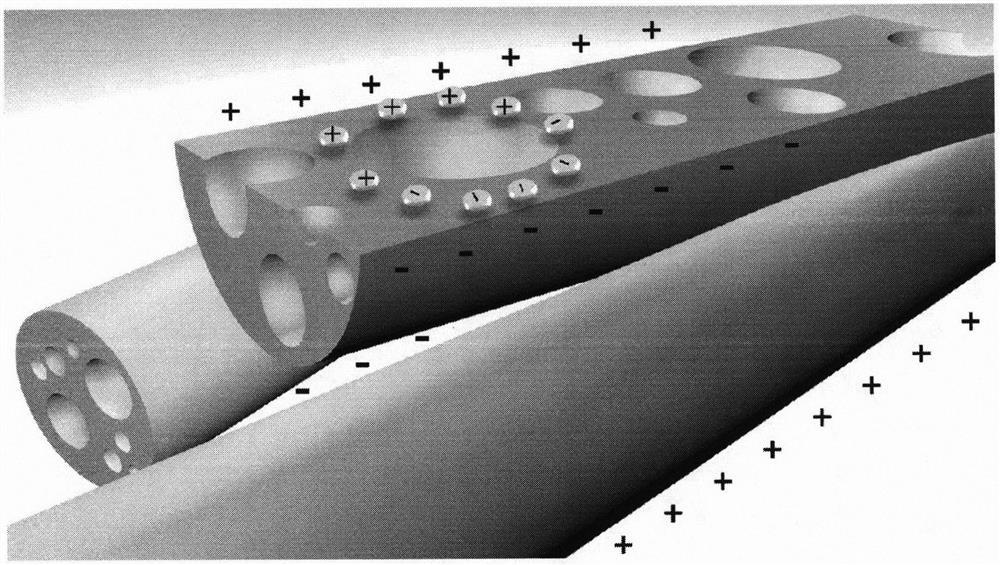

A technology of electrospinning and fiber materials, which is applied in the field of fiber materials, and can solve problems such as cell structure enhancement of electret performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In this embodiment, an in-situ water electret method based on electrospinning is provided. A ring-shaped water spray device is arranged around the jet flow to increase high pressure to atomize water molecules. The macroscopic motion direction of the atomized water molecules and high-speed flight The angle between the moving directions of the charged jet is 10°; the particle size of the atomized water molecule is 80 μm; the water is ultrapure water; the main component of the fiber is polyvinylidene fluoride, the form is powder, the molecular weight is 50000, the solvent It is N-N dimethylformamide, and the mass concentration of the colloidal solution formed is 20wt%; the process conditions of electrospinning are: voltage 18KV, receiving distance 20cm, injection speed 1mL / h, temperature 20℃, relative humidity 87%, spinning Silk time 1h.

Embodiment 2

[0022] In this embodiment, an in-situ water electret method based on electrospinning is provided. A ring-shaped water spray device is arranged around the jet flow to increase high pressure to atomize water molecules. The macroscopic motion direction of the atomized water molecules and high-speed flight The angle between the moving directions of the charged jet is 30°; the atomized water molecular size is 100 μm; the water is deionized water; the main component of the fiber is polycarbonate, the form is powder, the molecular weight is 100,000, and the solvent is Acetone, the mass concentration of the formed colloidal solution is 23wt%; the process conditions of electrospinning are: voltage 25KV, receiving distance 20cm, injection speed 3mL / h, temperature 30℃, relative humidity 90%, spinning time 1h.

Embodiment 3

[0024] In this embodiment, an in-situ water electret method based on electrospinning, when the aqueous spinning solution flows out from a needle with high-voltage static electricity, the water molecules are broken into fine droplets or jets under the action of high-voltage electricity, The fibers were electreted by friction with the nanofibers, and the water content in the spinning solution was 10%. The particle size of the atomized water molecule is 80 μm; the water is deionized water; the main component of the fiber is polyvinyl chloride, the form is liquid, the molecular weight is 30000, the solvent is tetrahydrofuran, and the mass concentration of the formed colloid solution is 30wt%; electrostatic The spinning process conditions were: voltage 18KV, receiving distance 20cm, injection speed 2mL / h, temperature 25°C, relative humidity 95%, and spinning time 1h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com