N-doped MXene material and preparation method and application thereof

A ceramic material, ammonia technology, applied in the manufacture of hybrid/electric double-layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of unfavorable large-scale preparation, destabilized structure, long reaction period, etc., achieve excellent electrochemical performance, improve Safety, compact and regular effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] To prepare N-doped MXene materials, the specific steps are as follows:

[0034] 1) Single or few layers of Ti 3 C 2 T X Preparation: 3g Ti 3 C 2 Slowly add Al powder to 30mL 48wt% hydrofluoric acid solution, stir at 38°C for 72h, centrifuge to remove the supernatant, pour deionized water, repeat the cleaning-centrifugation process until the pH of the supernatant is 6, and collect the precipitate and vacuum-dried to obtain "accordion-like" multi-layer stacked Ti 3 C 2 Tx, then the resulting Ti 3 C 2 Tx (about 2g) was placed in 20mL DMSO for stirring intercalation treatment, the stirring rate was 800-1000r / min, and then centrifuged for 6-8 times under the condition of water medium, and finally ultrasonic stripping was carried out, and the supernatant liquid was taken by low-speed centrifugation and placed in vacuum at 60°C. Dry in a drying oven for 48 hours to obtain single-layer or few-layer Ti 3 C 2 T X phase material;

[0035] 2) Preparation of N-doped MXen...

Embodiment 2

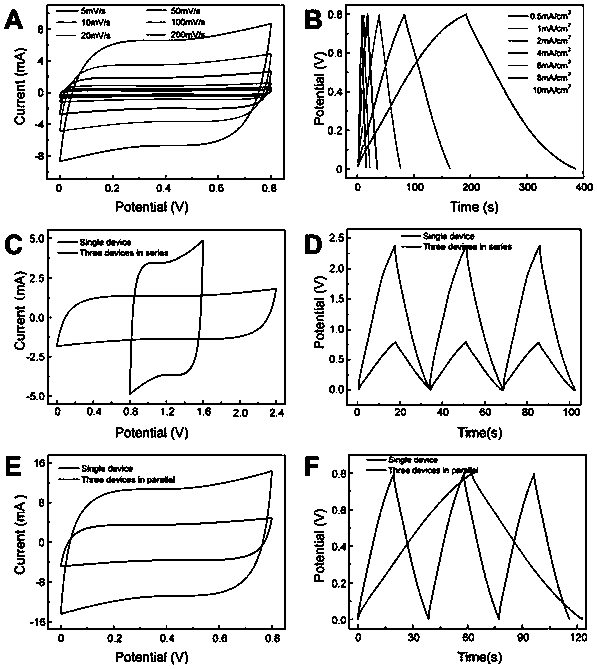

[0040] Utilize the N-doped MXene material (N-Ti prepared by embodiment 1 3 C 2 T x ) to prepare paper-based microcapacitors, the specific method is as follows: 100mg of Ti 3 C 2 T X Prepare 10mL of an aqueous solution with a concentration of 10mg / mL, and use vacuum filtration to add 0.2mL of 10mg / mL conductive silver paste into a suction filter funnel filled with 300mL of ethyl acetate for suction filtration, and then take 0.2mL of 10mg / mL N-Ti 3 C 2 T x The aqueous solution was placed in 300mL deionized water, and pumped sequentially onto a paper chip made of UV ordered lithography SU-8 glue coated with ordinary filter paper (soak the filter paper in the solution of photosensitive reagent SU-8, make SU-8 Coat evenly on the filter paper under the action of a homogenizer, the homogenization time is 30-120s, and then put the above-mentioned filter paper coated with SU-8 optical glue in an oven, bake at 60-90℃ for 12-24h , UV lithography was carried out under the protecti...

Embodiment 3

[0043] The N-doped MXene material was prepared by a method similar to Example 1. The difference from Example 1 was that the flow rate of ammonia gas was 100 sccm, the flow rate of argon gas was 100 sccm, and the temperature was raised to 300 at a rate of 5 °C / min at room temperature. ℃, heat preservation for 2h for calcination to obtain N-Ti 3 C 2 T x .

[0044] Prepare paper-based microcapacitors, the specific method is as follows: take 100mg of the N-Ti prepared above 3 C 2 T x Prepare 10mL of an aqueous solution with a concentration of 10mg / mL, and use vacuum filtration to add 0.2mL of 10mg / mL conductive silver paste into a suction filter funnel filled with 300mL of ethyl acetate for suction filtration, and then take 0.2mL of 10mg / mL N-Ti 3 C 2 T x The aqueous solution was placed in 300mL deionized water, and sequentially pumped onto a paper chip made of ordinary filter paper coated with SU-8 glue coated with UV-ordered lithography, and taken out and placed at room...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com