MAX phase ceramic and composite material surface modification processing method thereof

A composite material and surface modification technology, applied in anodizing and other directions, can solve the problems of lack of necessity, difficulty in realizing plasma discharge, and inability to perform micro-arc oxidation treatment, and achieve the effect of broadening the application field, compact structure and smooth surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Specimen is Ti 3 AlC 2 , the surface is polished with 600~2000# water-resistant sandpaper, and then degreased and cleaned with acetone, alcohol, deionized water, etc., and dried. Then immerse the cleaned test piece in the anolyte, the solution consists of 15g / L Na 2 SiO 3 , 6g / L of NaOH, 8g / L of KF, and the balance of deionized water. Using pulse power supply, current density 20mA / cm 2 , the frequency is 600Hz, the duty cycle is 30%, the electrolytic solution has been subjected to electromagnetic stirring, the temperature is maintained at 40°C, the treatment time is 15min, and the termination voltage is 400V. Afterwards, the sample was rinsed with distilled water and dried, and the oxide film layer was mainly composed of Al 2 o 3 and TiO 2 Group and part of Al 2 TiO 5 composition.

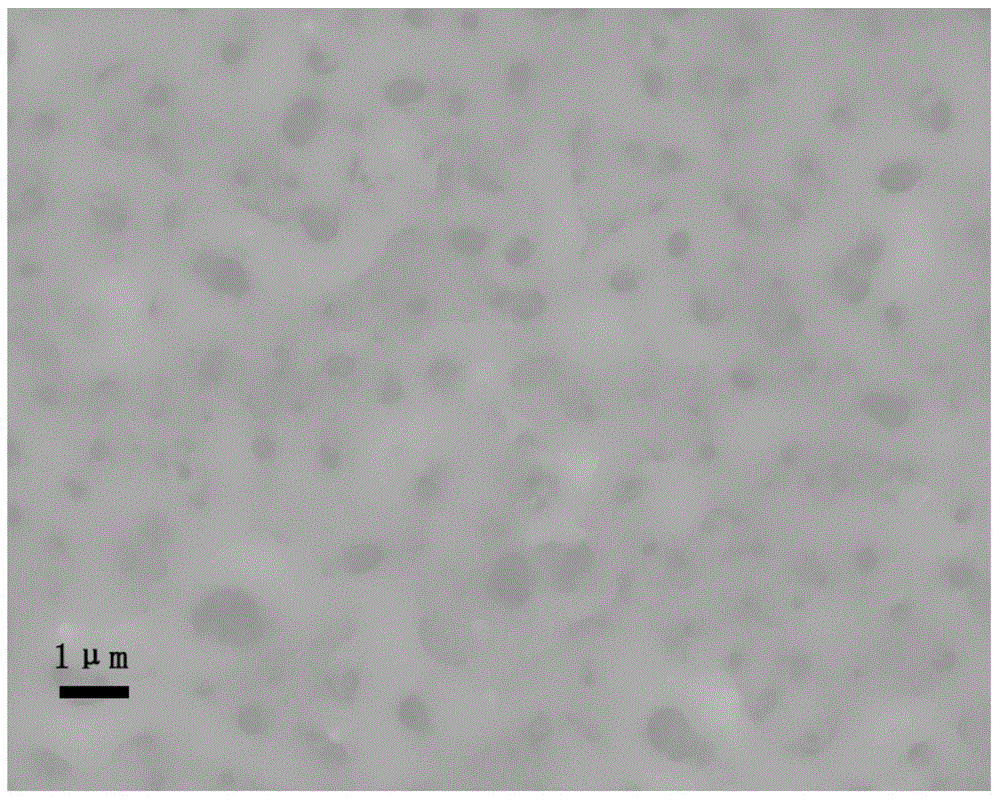

[0034] The surface morphology of the prepared oxide film is shown in the appendix figure 1 . Depend on figure 1 It can be seen that after micro-arc oxidation, Ti 3 AlC 2 The s...

Embodiment 2

[0037] Specimen is Ti 3 (Si 0.95 al 0.05 )C 2 , the surface is polished with 600-2000# water-resistant sandpaper, and then degreased and cleaned with acetone, alcohol, deionized water, etc., and dried. Then immerse the workpiece in the anolyte, the solution consists of 30g / L Na 2 SiO 3 , 10g / L of NaOH, 20g / L of KF, and the balance of deionized water. Using pulse power supply, the current density is 35mA / cm 2 , the frequency is 800Hz, the duty cycle is 35%, the electrolytic solution has been subjected to electromagnetic stirring, the temperature is maintained at 30°C, the treatment time is 20min, and the termination voltage is 500V. Afterwards, the sample was rinsed with self-distilled water and dried, and the oxide film layer was mainly composed of TiO 2 and some Al 2 TiO 5 Composition, a small amount of Si to amorphous SiO 2 form exists. The thickness of the film layer is 4 μm, and the hardness is 9.5 GPa.

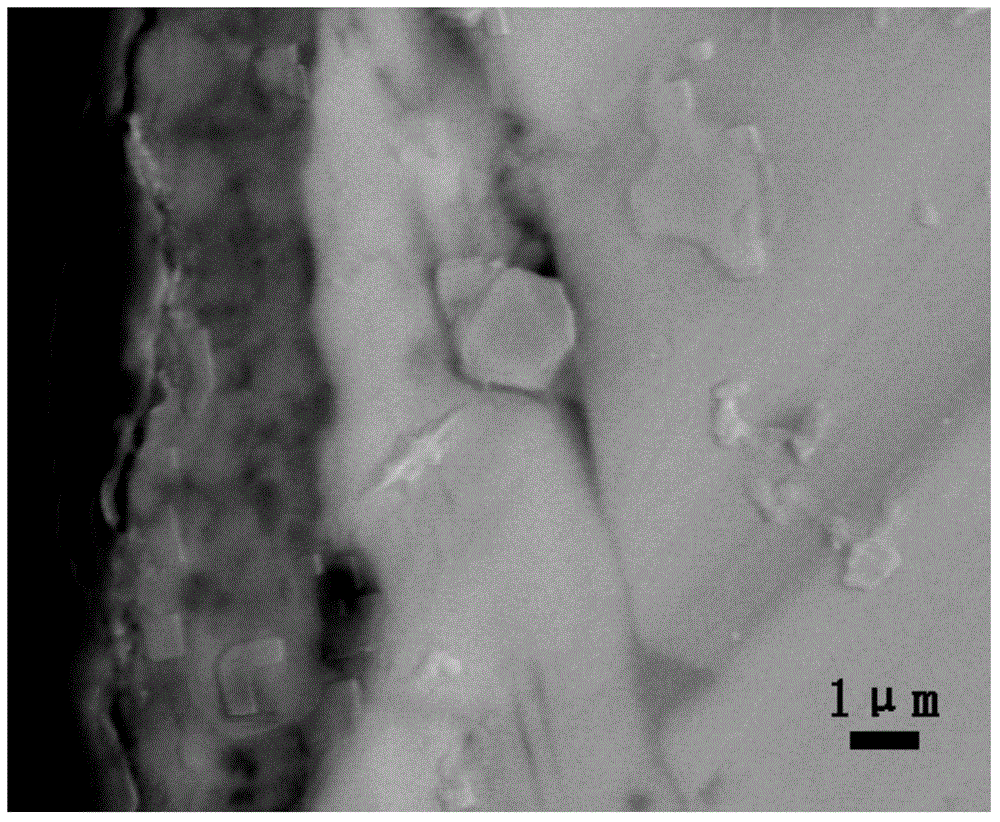

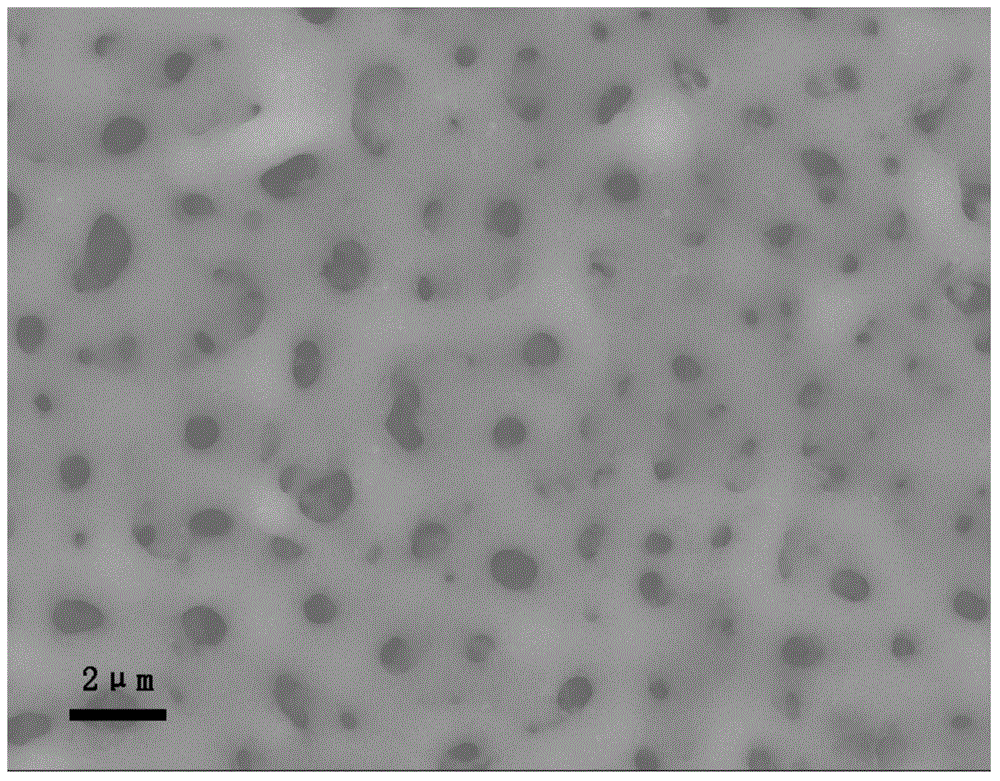

[0038] The surface morphology of the prepared oxide film...

Embodiment 3

[0041] Specimen is Ti 3 SiC 2 -2vol.% Al 2 o 3 , the surface is polished with 600~2000# sandpaper, cleaned with acetone alcohol and deionized water, and dried. Then immerse the sample in the anolyte, the solution consists of 20g / L NaAlO 2 , 4g / L of NaOH, 15g / L of KF, 3mL / L of 30wt%H 2 o 2 (Its role is to react in the solution to provide the necessary O for film formation 2 , increase the film forming speed and film thickness), and the remaining deionized water is composed of a pulse power supply with a current density of 40mA / cm 2 , the frequency is 1000Hz, the duty cycle is 30%, the electrolytic solution has been subjected to electromagnetic stirring, the temperature is maintained at 45°C, the treatment time is 60min, and the termination voltage is 600V. The samples were then rinsed with distilled water and dried. The thickness of the oxide film layer is 50 μm, the surface is uniform, and it is well combined with the substrate.

[0042] To sum up the above three embo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com