MXene material and preparation method and application thereof

A high-temperature reaction, 1axn technology, applied in chemical instruments and methods, rare earth metal compounds, inorganic chemistry, etc., to achieve the effect of simple and easy preparation methods and rich and adjustable space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

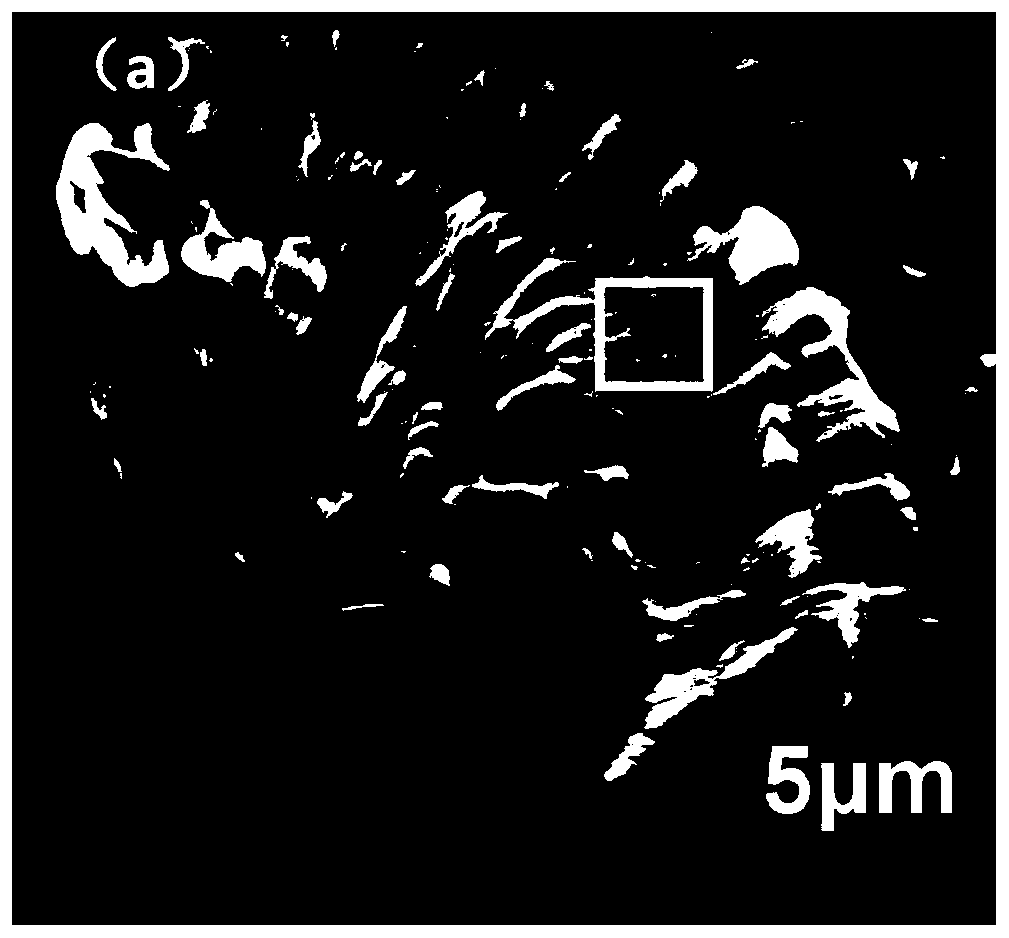

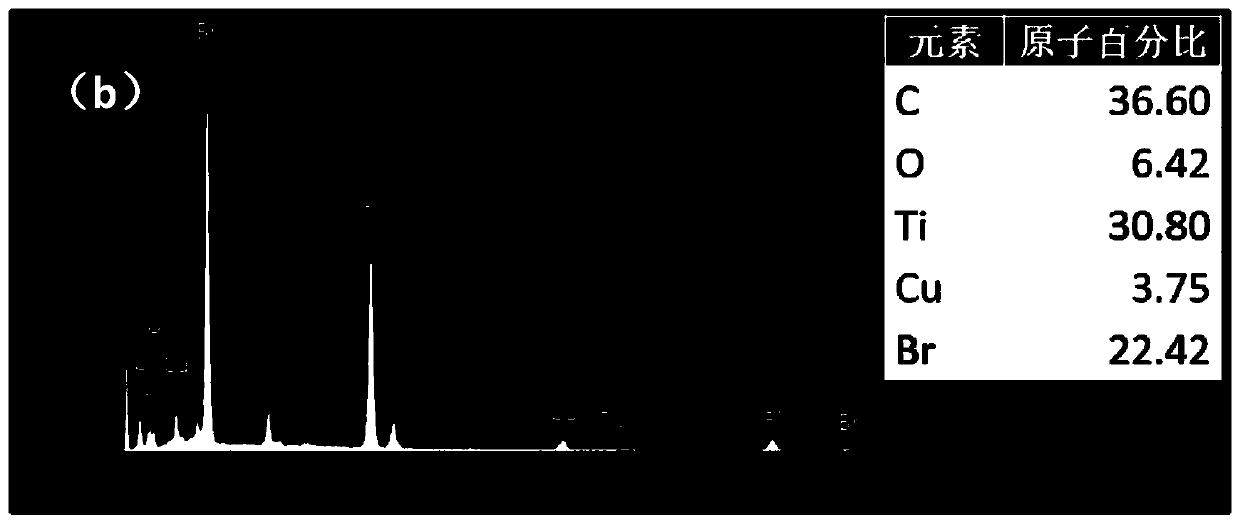

[0037] In this embodiment, the MXene material with Br as the surface group is Ti 3 C 2 Br 2 , the precursor MAX phase is Ti 3 AlC 2 , the transition metal chloride is CuBr 2 , and these raw materials can be obtained through commercially available channels and the like. The Ti 3 C 2 Br 2 The preparation method is as follows:

[0038] (1) Weigh CuBr 2 0.15 mol, Ti with a particle size of 10 μm 3 AlC 2 0.05 moles of powder, and the above materials were ground and mixed to obtain a mixed product.

[0039] (2) Put the mixture in a corundum crucible and put it into a high-temperature tube furnace for reaction. The reaction conditions are: 700°C, 7 hours, under argon protection. After the temperature of the tube furnace dropped to room temperature, the reaction product in the crucible was taken out.

[0040] (3) Wash the reaction product with deionized water: put the reaction product into a beaker, add deionized water, stir and ultrasonically clean for 30 minutes, then...

Embodiment 2

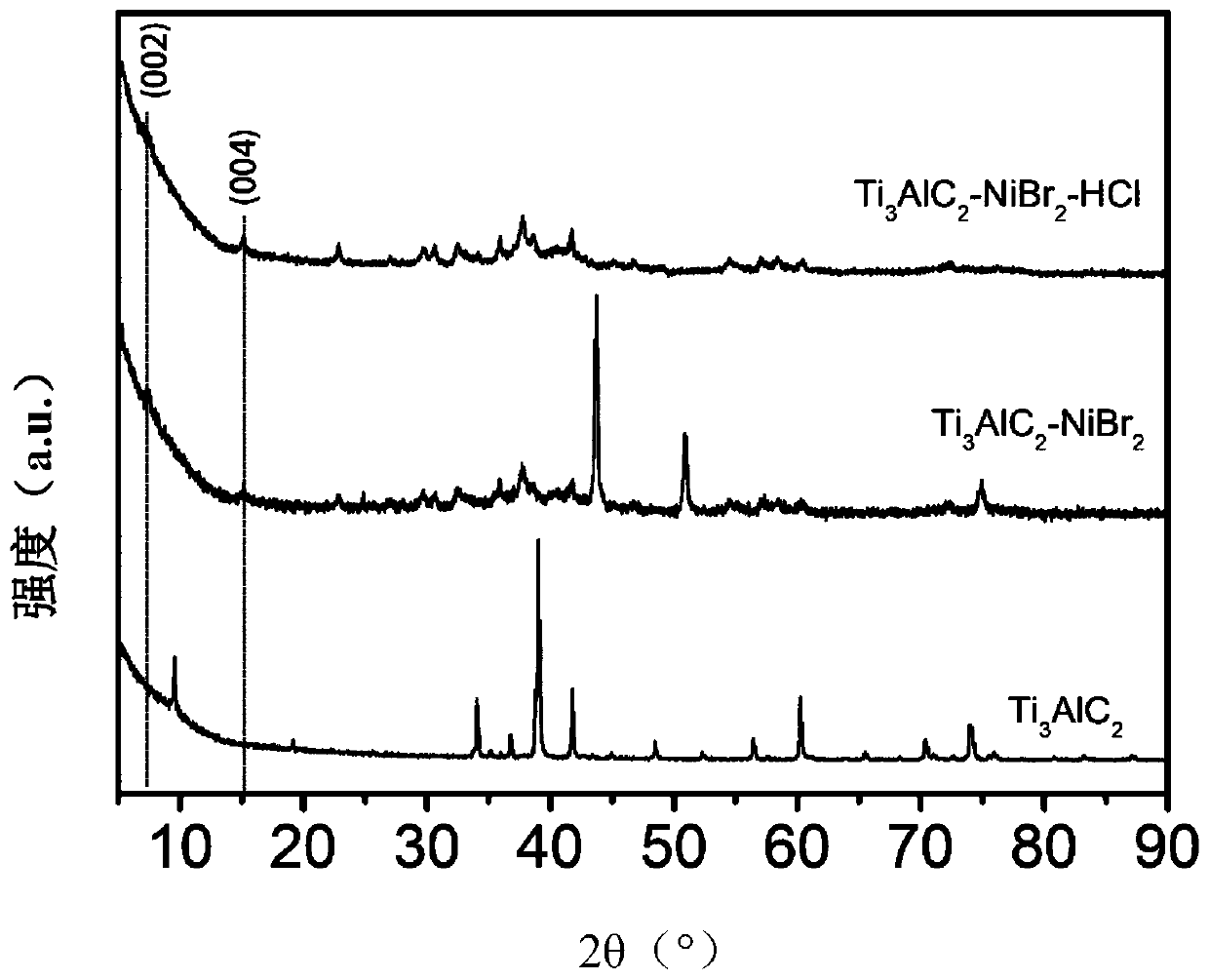

[0044] In this embodiment, the MXene material with Br as the surface group is Ti 3 C 2 Br 2 , the precursor MAX phase is Ti 3 AlC 2 , the transition metal chloride is NiBr 2 , and these raw materials can be obtained through commercially available channels and the like. The Ti 3 C 2 Br 2 The preparation method is as follows:

[0045] (1) Weigh NiBr 2 0.75 mol, Ti with a particle size of 10 μm 3 AlC 2 0.05 moles of powder, and the above materials were ground and mixed to obtain a mixed product.

[0046] (2) Put the mixture in a corundum crucible and put it into a high-temperature tube furnace for reaction. The reaction conditions are: 700°C, 7 hours, under argon protection. After the temperature of the tube furnace dropped to room temperature, the reaction product in the crucible was taken out.

[0047] (3) Wash the reaction product with deionized water: put the reaction product into a beaker, add deionized water, stir and ultrasonically clean for 30 minutes, then...

Embodiment 3

[0052] In this embodiment, the MXene material with I as the surface group is Ti 3 C 2 I 2 , the precursor MAX phase is Ti 3 AlC 2 , the transition metal chloride is CuI 2 , and these raw materials can be obtained through commercially available channels and the like. The Ti 3 C 2 I 2 The preparation method is as follows:

[0053] (1) Weigh CuI 2 0.3 mol, Ti with a particle size of 10 μm 3 AlC 2 0.05 moles of powder, and the above materials were ground and mixed to obtain a mixed product.

[0054] (2) Put the mixture in a corundum crucible and put it into a high-temperature tube furnace for reaction. The reaction conditions are: 700° C., 12 hours, under argon protection. After the temperature of the tube furnace dropped to room temperature, the reaction product in the crucible was taken out.

[0055] (3) Wash the reaction product with deionized water: put the reaction product into a beaker, add deionized water, stir and ultrasonically clean for 30 minutes, then le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com