Dynamic/static scroll plate of no-oil scroll air compressor and nickel and boron plating process thereof

A static scroll, nickel-boron plating technology, applied in the field of scroll compressors, can solve the problem that the thickness and uniformity of the oxide film cannot be accurately controlled, the oxide film coating affects the heat dissipation performance of the scroll, and the accuracy cannot meet the qualified accuracy requirements, etc. problems, to achieve the effect of improving operating conditions, reducing friction, and reducing failure rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

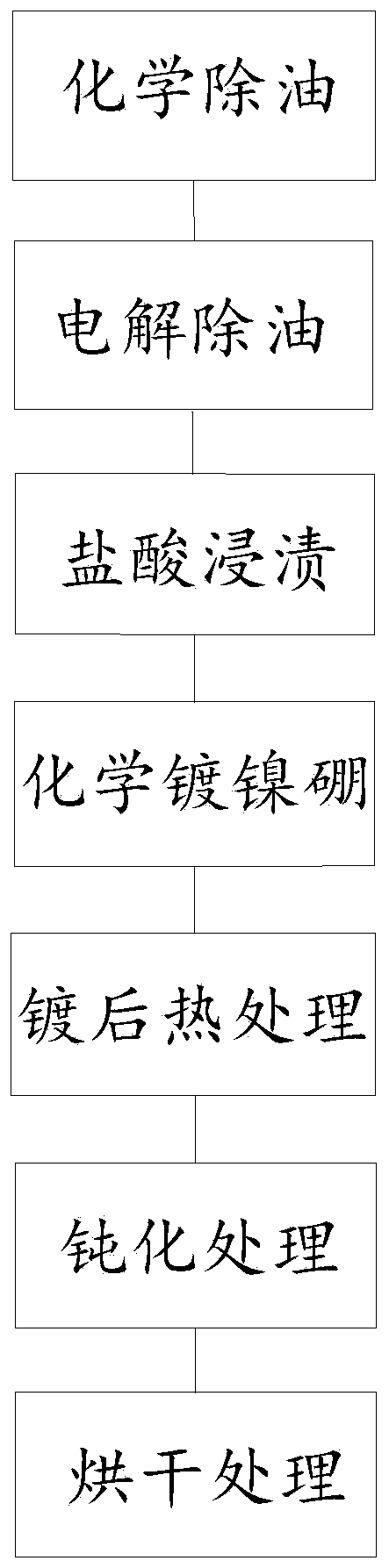

[0054] An oil-free scroll air compressor motor, fixed scroll nickel boron plating process, the specific steps are as follows:

[0055] Step 1, chemical degreasing, put the oil-free vortex air compressor motor and static vortex in the mixed solution tank of sodium hydroxide, sodium carbonate and sodium metaborate in a mass ratio of 2:3:3 to remove surface oil stains, mix The temperature in the solution tank is 80°C, the chemical degreasing time is 10 minutes, and then washed several times with water;

[0056] Step 2, electrolytic degreasing, the oil-free vortex air compressor motor, the static vortex are placed in the mixed solution electrolytic cell of sodium hydroxide, sodium carbonate and sodium metaborate according to the mass ratio of 2:3:3, alkaline solution The temperature in the electrolytic cell is 80°C. First, the oil-free scroll air compressor motor and static scroll disk are used as the cathode to degrease. The cathode reaction time is 3 minutes, and then the oil-fr...

Embodiment 2

[0063] An oil-free scroll air compressor motor, fixed scroll nickel boron plating process, the specific steps are as follows:

[0064] Step 1, chemical degreasing, put the oil-free vortex air compressor motor and static vortex in the mixed solution tank of sodium hydroxide, sodium carbonate and sodium metaborate in a mass ratio of 2:3:3 to remove surface oil stains, mix The temperature in the solution tank is 60°C, and the chemical degreasing time is 30 minutes, followed by multiple washings;

[0065] Step 2, electrolytic degreasing, the oil-free vortex air compressor motor, the static vortex are placed in the mixed solution electrolytic cell of sodium hydroxide, sodium carbonate and sodium metaborate according to the mass ratio of 2:3:3, alkaline solution The temperature in the electrolytic cell is 60°C. First, the oil-free scroll air compressor motor and the static scroll disk are used as the cathode for degreasing. The cathode reaction time is 7 minutes, and then the oil-fr...

Embodiment 3

[0072] An oil-free scroll air compressor motor, fixed scroll nickel boron plating process, the specific steps are as follows:

[0073] Step 1, chemical degreasing, put the oil-free vortex air compressor motor and static vortex in the mixed solution tank of sodium hydroxide, sodium carbonate and sodium metaborate in a mass ratio of 2:3:3 to remove surface oil stains, mix The temperature in the solution tank is 70°C, and the chemical degreasing time is 20 minutes, followed by multiple washings;

[0074] Step 2, electrolytic degreasing, the oil-free scroll air compressor motor, the static scroll disc are placed in the alkaline solution electrolytic cell of sodium hydroxide, sodium carbonate and sodium metaborate by 2:3:3 mass ratio, alkaline The temperature in the solution electrolytic cell is 75°C. Firstly, the motorized oil-free scroll air compressor and the static scroll disk are used as the cathode to remove the oil. The cathode reaction time is 5 minutes, and then the motori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com