Butylphthalide transdermal patch and preparation method thereof

A butylphthalide and patch technology, applied in the field of medicine, can solve the problems of low oral availability of butylphthalide soft capsules, poor patient compliance of injection dosage forms, complicated injection preparation process, etc., so as to increase the effective availability and reduce the The number of doses and the effect of avoiding adverse reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

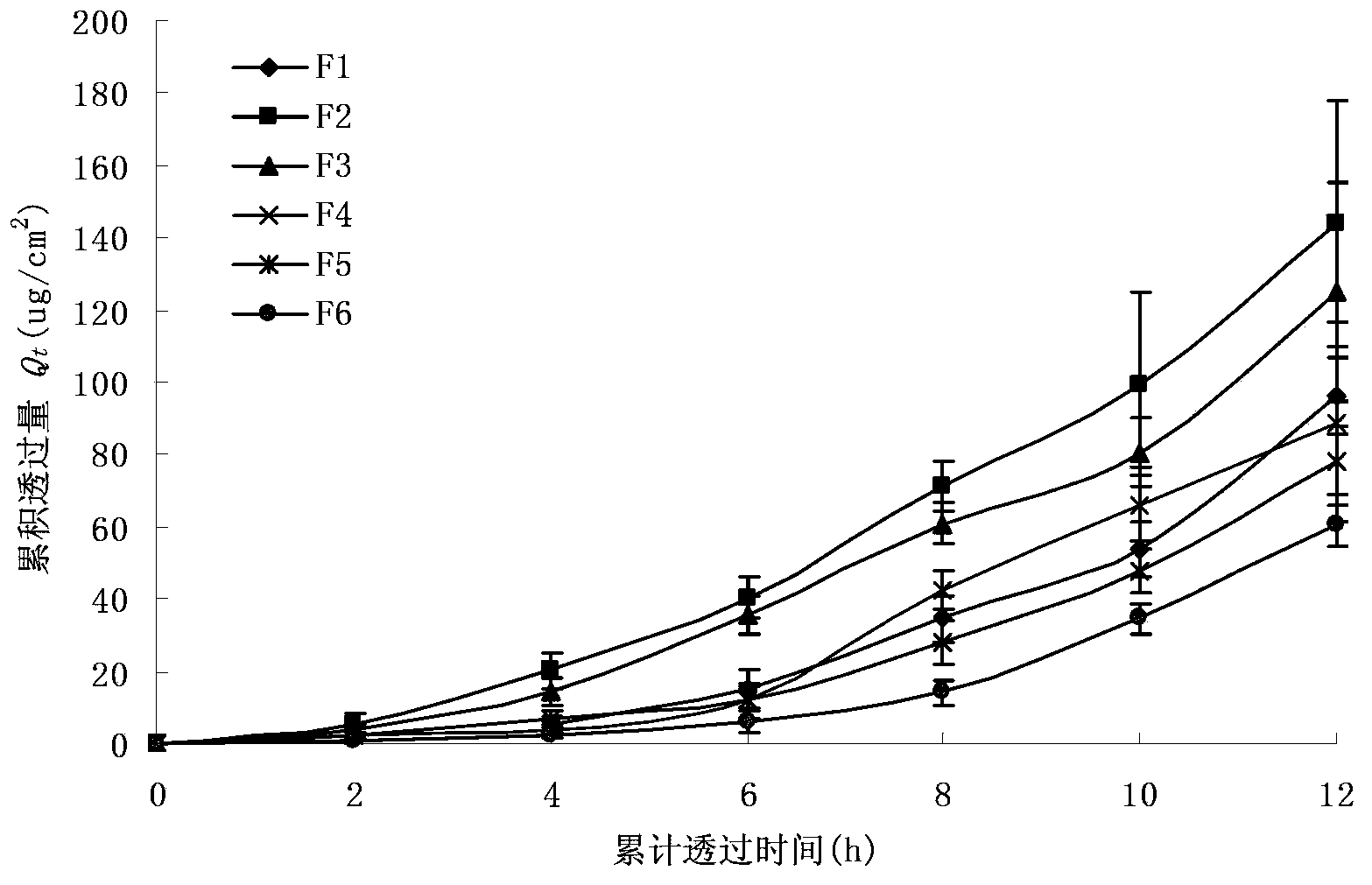

Image

Examples

Embodiment 1

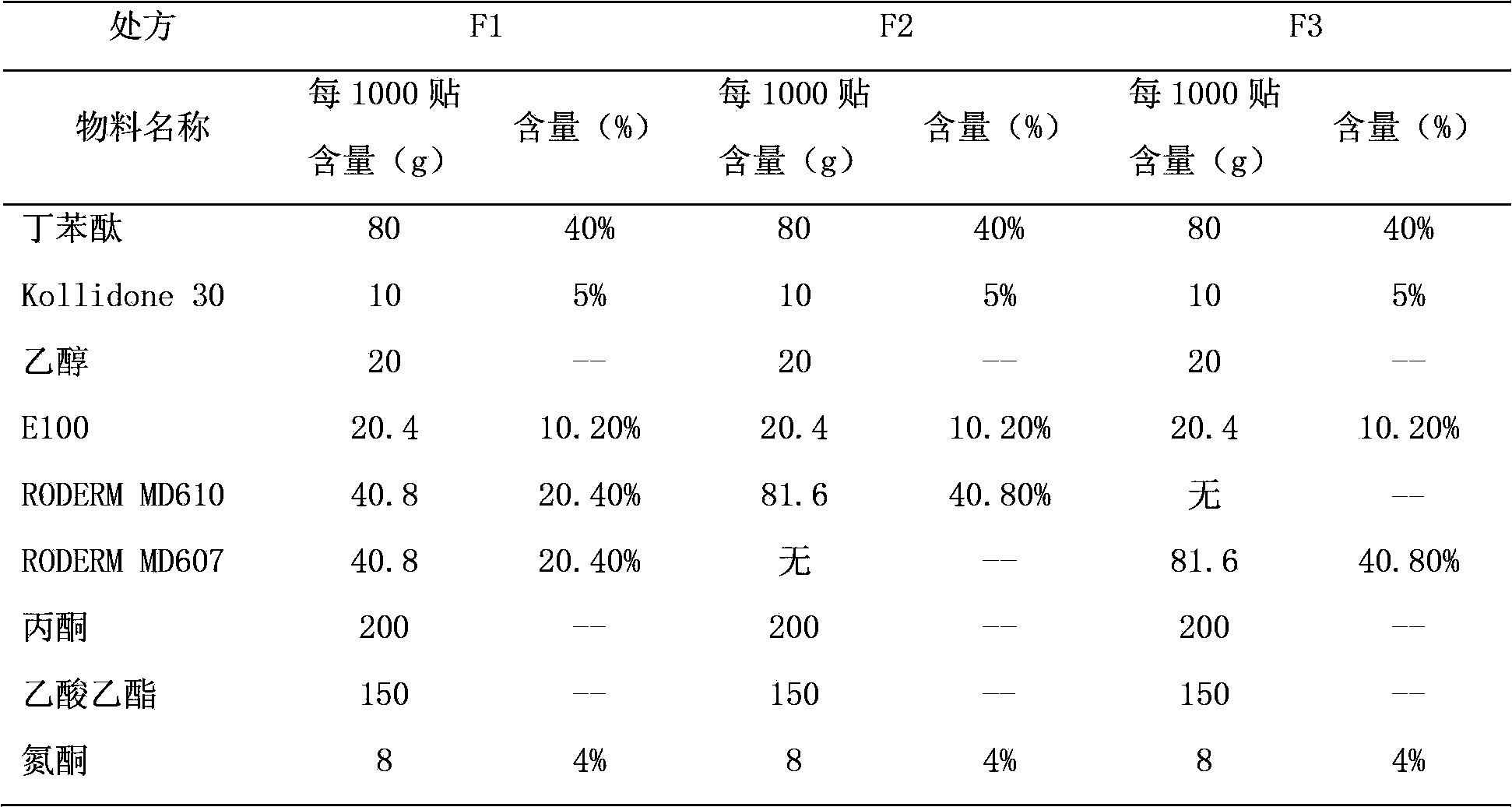

[0048] A kind of butylphthalide transdermal patch comprises the following components by weight percent:

[0049]

[0050] The preparation method of butylphthalide transdermal patch comprises the steps:

[0051] ① Add butylphthalide to ethanol dissolved with a certain amount of PVP K30, and stir evenly;

[0052] ② Dissolve E100 and RODERM MD610 / 607 with acetone and ethyl acetate and stir well;

[0053] ③Mix the above liquids together, add azone, stir evenly, transfer to the coating machine, coat on the anti-adhesive layer, heat up and dry at 40°C for 2 hours, then cover with the backing layer, punch out to a certain size size and specifications. The thickness of the drug-loaded pressure-sensitive adhesive layer can be 20-200 μm.

Embodiment 2

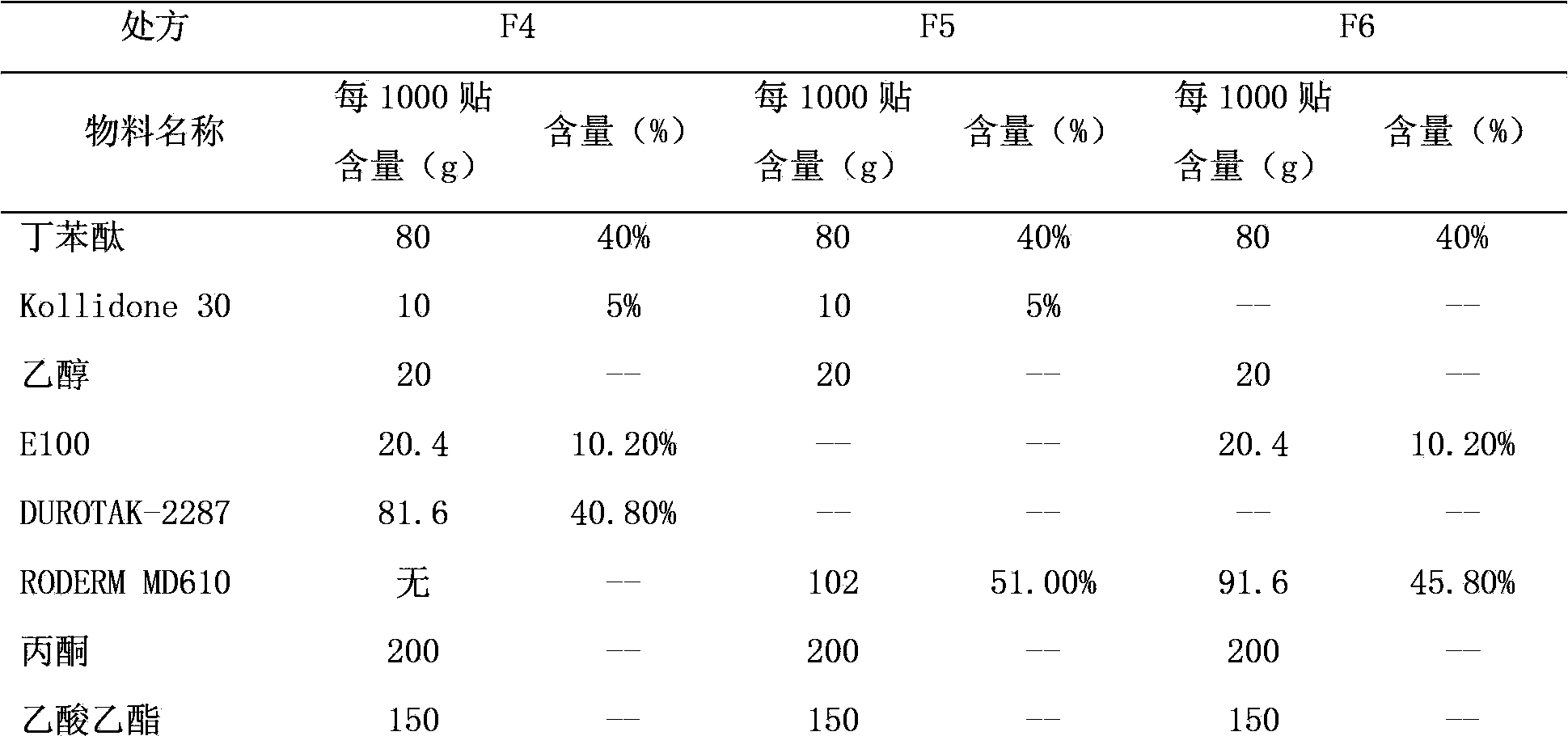

[0055]

[0056]

[0057] The preparation method of butylphthalide transdermal patch comprises the steps:

[0058] ① Add butylphthalide to ethanol dissolved with a certain amount of PVP K30, and stir evenly;

[0059] ②E100 and DUROTAK-2287 were dissolved with acetone and ethyl acetate and stirred evenly;

[0060] ③Mix the above liquids together, add azone, stir evenly, transfer to the coating machine, coat on the anti-adhesive layer, heat up and dry at 40°C for 2 hours, then cover with the backing layer, punch out to a certain size size and specifications. The thickness of the drug-loaded pressure-sensitive adhesive layer can be 20-200 μm.

Embodiment 3

[0062] The appearance, initial adhesion and holding force of the prepared patches were compared and investigated, and 3 patch samples (15cm 2 / piece), and the results are shown in Table 1.

[0063] Table 1 The results of the sample appearance and viscosity characteristics investigation

[0064]

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com