Method for preparing MAX phase ceramic Ti3AlC2 powder by molten salt method low temperature sintering

A technology of low temperature sintering and molten salt method, applied in the field of ternary layered MAX phase ceramic powder preparation, can solve the problems of lower sintering temperature, high sintering temperature, no simple operation, etc. The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

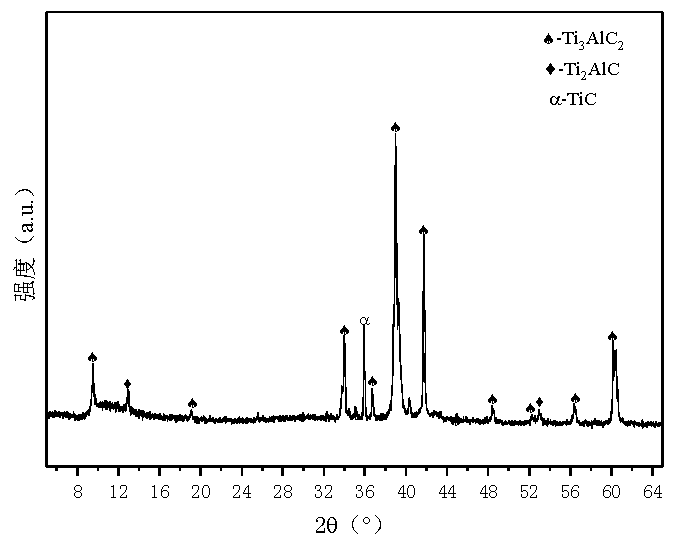

Embodiment 1

[0044] With TiH 2 Powder (325 mesh, 99%), aluminum powder (1-2 μm), TiC powder (2-4 μm, 99%) are used as raw materials. Raw materials according to Ti 3 AlC 2 The stoichiometric ratio is proportioned, and an excess of 10at% aluminum powder is used; the raw materials are mixed and roller milled for 12 hours to obtain a uniformly mixed powder. Place the well-mixed powder in Al 2 o 3 Put the crucible into a vacuum tube furnace, and then pass in flowing Ar as a protective atmosphere, raise the temperature to 1000°C at a heating rate of 5°C / min, and then raise the temperature to 1250°C at a heating rate of 3°C / min. Keep it warm for 2 hours, then lower the temperature to 1000°C at a rate of 3°C / min, and then cool down to room temperature with the furnace. After the block is cooled, take it out and grind it. Prepared Ti 3 AlC 2 The XRD pattern of the powder is as follows figure 1 shown. Calculated by the XRD characteristic peak intensity of the sample, Ti in the sintered sam...

Embodiment 2

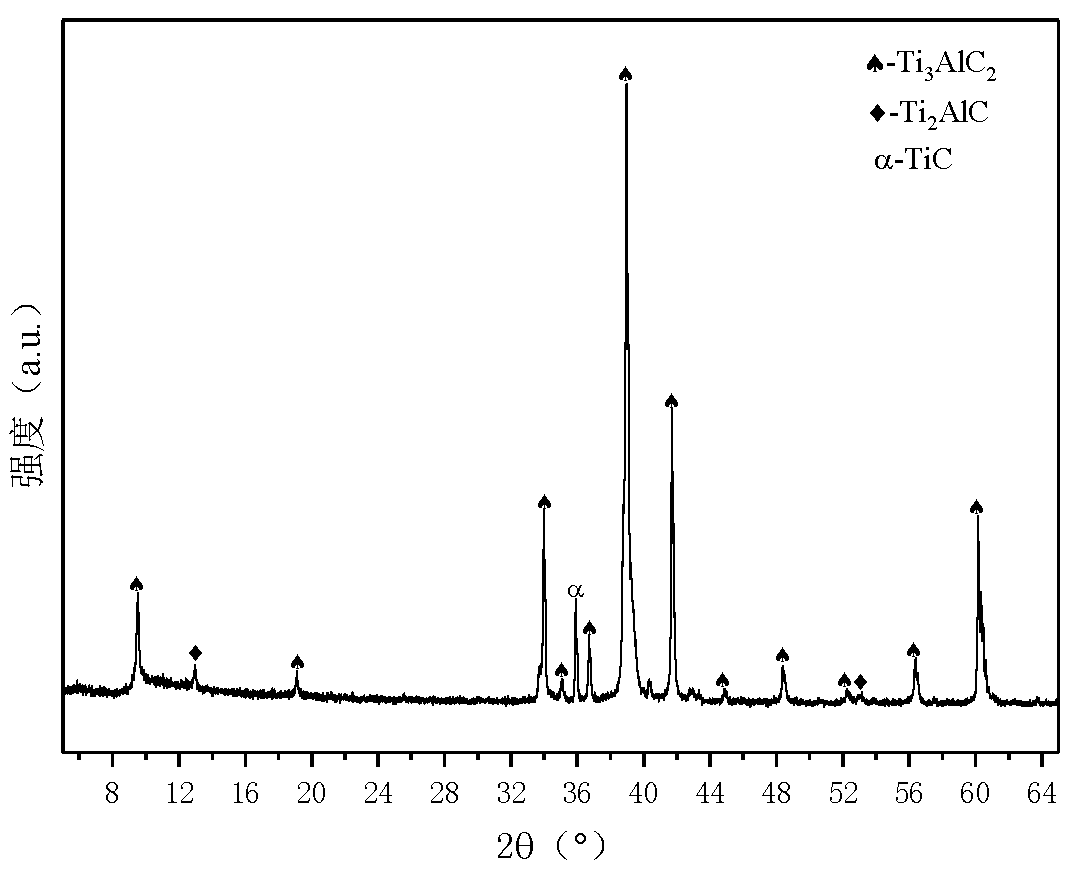

[0046] With TiH 2 Powder (325 mesh, 99%), aluminum powder (1-2 μm), TiC powder (2-4 μm, 99%) are used as raw materials. Raw materials according to Ti 3 AlC 2 The stoichiometric ratio is proportioned, and an excess of 10at% aluminum powder is used; KCl and raw materials are weighed and mixed according to a mass ratio of 2:1, and a uniformly mixed powder is obtained after roller milling for 12 hours. Place the well-mixed powder in Al 2 o 3 Then put the crucible into a vacuum tube furnace, then pass flowing Ar as a protective atmosphere, raise the temperature to 1000°C at a heating rate of 5°C / min, keep it for 5 hours, and then cool to room temperature with the furnace. After the block is cooled, take it out, grind it, and wash away the molten salt with deionized water until the titration of AgNO 3 No precipitation, placed in an environment of 80 ° C for 24 hours to dry Ti 3 AlC 2 Powder. Prepared Ti 3 AlC 2 The XRD pattern of the powder is as follows figure 2 shown. ...

Embodiment 3

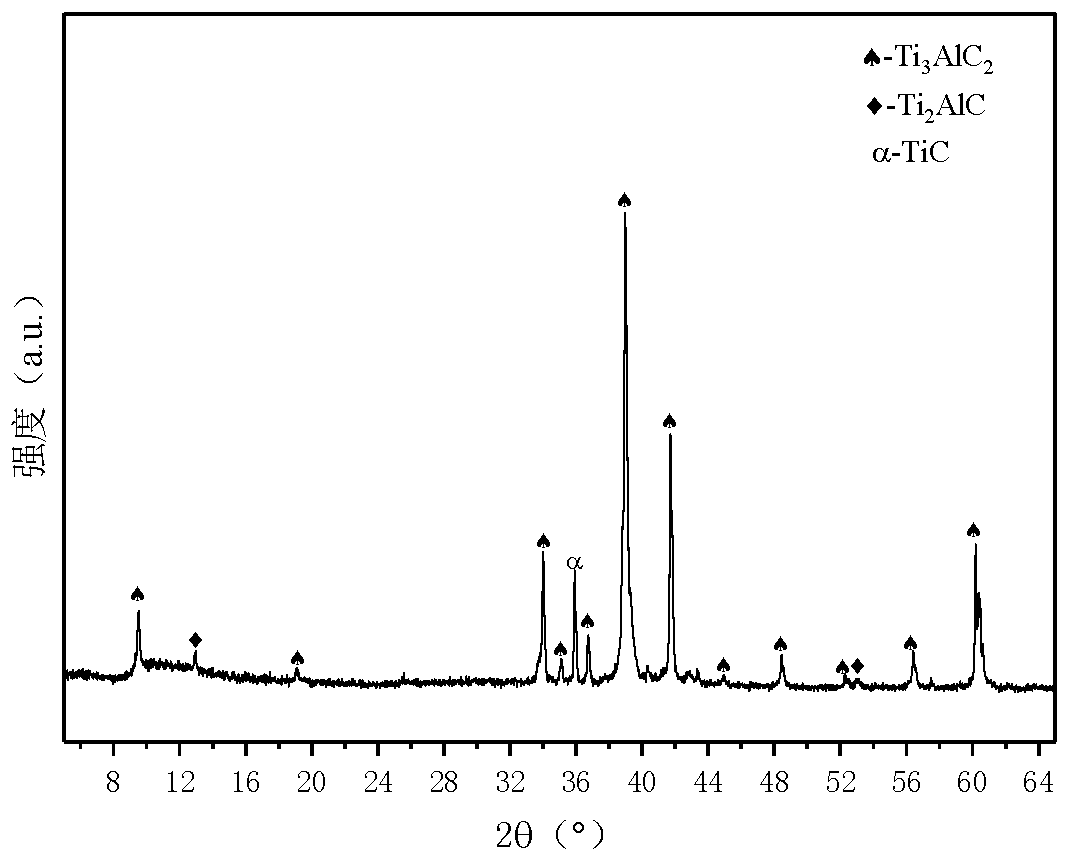

[0048] With TiH 2 Powder (325 mesh, 99%), aluminum powder (1-2 μm), TiC powder (2-4 μm, 99%) are used as raw materials. Raw materials according to Ti 3 AlC 2 The stoichiometric ratio is proportioned, and an excess of 10at% aluminum powder is used; KCl and raw materials are weighed and mixed according to a mass ratio of 5:1, and a uniformly mixed powder is obtained after roller milling for 12 hours. Place the well-mixed powder in Al 2 o 3 Then put the crucible into a vacuum tube furnace, then pass flowing Ar as a protective atmosphere, raise the temperature to 1000°C at a heating rate of 5°C / min, keep it for 5 hours, and then cool to room temperature with the furnace. After the block is cooled, take it out, grind it, and wash away the molten salt with deionized water until the titration of AgNO 3 No precipitation, placed in an environment of 80 ° C for 24 hours to dry Ti 3 AlC 2 Powder. Prepared Ti 3 AlC 2 The XRD pattern of the powder is as follows image 3 shown. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com