Preparation method of hybrid material, hybrid material and application of hybrid material

A technology of hybrid materials and metal carbonitrides, which is applied in chemical instruments and methods, ether preparation, separation methods, etc., can solve the problems of poor stability of MOFs, limit the application of MOFs, and structural collapse, so as to improve hydrothermal stability, The method is simple and the effect is excellent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

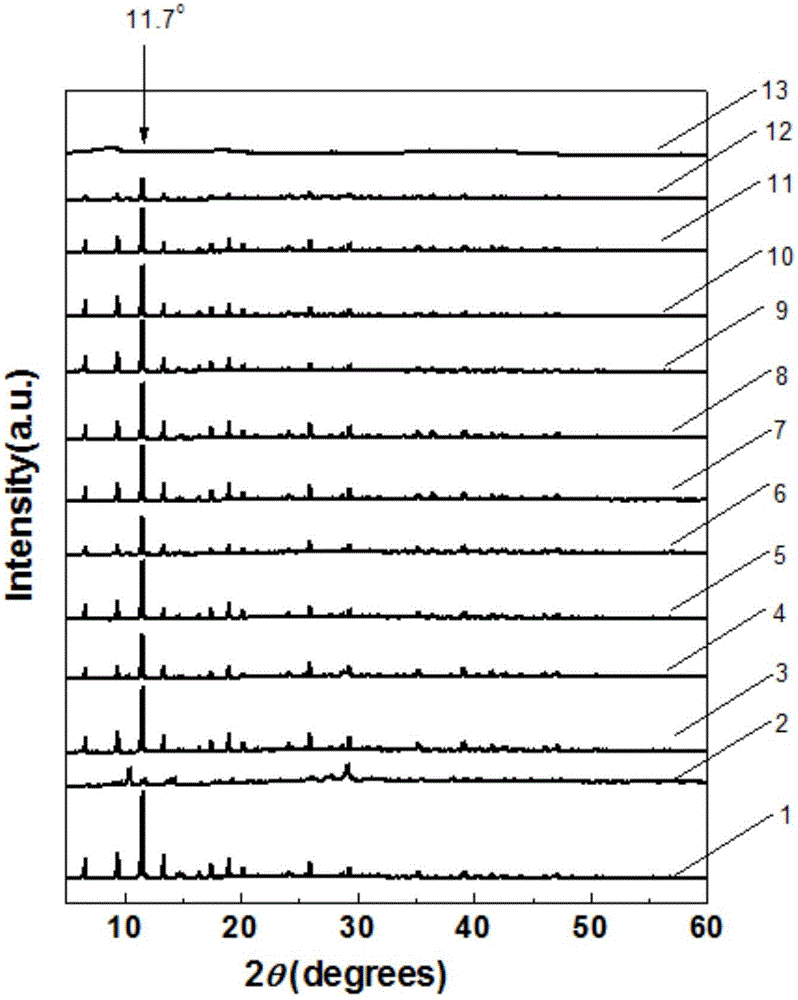

Method used

Image

Examples

preparation example Construction

[0043]Preparation of metal-organic framework HKUST-1: Weigh 0.5000g of copper nitrate trihydrate and 0.2500g of trimesic acid, add 4.25mL of N,N-dimethylformamide, absolute ethanol and water, stir for 1h, The above solution was stirred and reacted at 85° C. for 21 h. The sample was taken out and filtered, washed with N,N-dimethylformamide and absolute ethanol, taken out, soaked in dichloromethane and dried in the air to obtain metal organic framework HKUST-1.

[0044] Preparation of metal-organic framework MOF-5: Weigh 1.2100g of zinc nitrate hexahydrate and 0.3400g of terephthalic acid, add 40mL of N,N-dimethylformamide, stir for 15min, and react at 120°C. The reaction time is 24h. The sample was taken out and filtered, and washed with N,N-dimethylformamide to obtain the metal-organic framework MOF-5.

[0045] Preparation of metal-organic framework MIL-53Al: Weigh 0.7900g of aluminum nitrate nonahydrate and 0.3400g of terephthalic acid, add 40mL of hydrofluoric acid (48wt%)...

Embodiment 1

[0050] MXene-Ti 3 C 2 Preparation: weigh 1g Ti 3 AlC 2 Powder, add 10mL HF (49wt%), after reacting for 24h, wash with deionized water several times until the pH value of the solution is 6. Dry in a vacuum oven at 80°C for 20 hours to obtain MXene-Ti 3 C 2 .

[0051] Weigh 0.5000g of copper nitrate trihydrate, 0.2500g of trimesic acid and 0.0075g of MXene-Ti 3 C 2 , respectively added 4.25mL of N,N-dimethylformamide, absolute ethanol and water, stirred for 1h, and stirred and reacted the above solution at 85°C at 1000-2000rpm for a reaction time of 21h. Take out the sample and filter it, soak and wash it with N,N-dimethylformamide and absolute ethanol, take it out and soak it in dichloromethane and dry it to get the metal organic framework HKUST-1 and MXene-Ti 3 C 2 The hybrid material is calculated to be 85%.

Embodiment 2

[0053] MXene-Ti 3 C 2 Preparation: weigh 1g Ti 3 AlC 2 Powder, add 10mL HF (49wt%), after reacting for 24h, wash with deionized water several times until the pH value of the solution is 6. Dry in a vacuum oven at 80°C for 20 hours to obtain MXene-Ti 3 C 2 .

[0054] Weigh 0.5000g of copper nitrate trihydrate, 0.2500g of trimesic acid and 0.0225g of MXene-Ti 3 C 2 , respectively added 4.25mL of N,N-dimethylformamide, absolute ethanol and water, stirred for 1h, and stirred and reacted the above solution at a temperature of 85°C, and the reaction time was 21h. Take out the sample and filter it, wash it with N,N-dimethylformamide and absolute ethanol, soak it in dichloromethane and dry it to get metal organic framework HKUST-1 and MXene-Ti 3 C 2 The hybrid material was calculated to be 74%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com