Flexible MXene self-supporting membrane/metal composite material and preparation method and application thereof

A metal composite material, self-supporting film technology, applied in nanotechnology for materials and surface science, electrode manufacturing, nanotechnology, etc., can solve the problems of complex preparation process, complex preparation method, and safety of hydrofluoric acid. , to achieve the effect of improving overall electrical conductivity, excellent mechanical properties and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] A kind of preparation method of the flexible electrode of electroplating micronano metal Sb / Bi / Sn on MXene self-supporting film, comprises the steps:

[0049] (1) Add MAX powder into the mixed solution of acid and fluoride and stir, then add water to wash by centrifugation, then shake and centrifuge vigorously by hand to separate and obtain the exfoliated few-layer MXene suspension.

[0050] (2) The MXene suspension was filtered by vacuum filtration, and then vacuum-dried to obtain a flexible MXene self-supporting membrane.

[0051] (3) Put the MXene self-supporting film into the electroplating solution of solvent and metal salt, electroplate a layer of micro / nano-scale metal microspheres at a constant current, and then vacuum dry to obtain the electrode sheet.

[0052] In step (1), the MAX powder includes: Ti 3 AlC 2 、Ti 2 AlC, Ta 4 AlC 3 , TiNbAlC, (V 0.5 Cr 0.5 ) 3 AlC 2 , V 2 AlC, Nb 2 AlC, Nb 4 AlC 3 、Ti 3 AlCN, Ti 3 SiC 2 、Ti 2 SiC, Ta 4 SiC 3 ,...

Embodiment 1

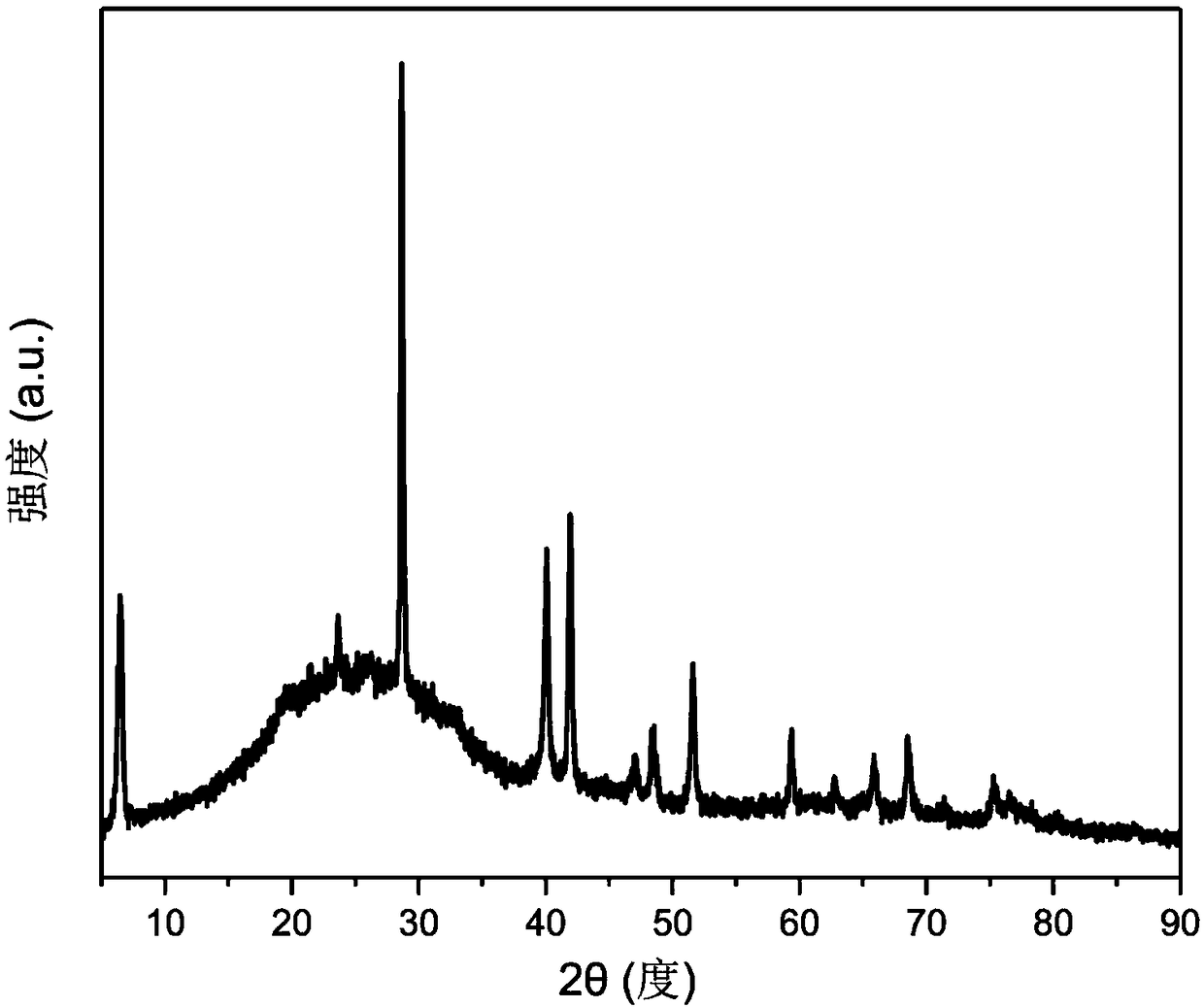

[0069] (1) MAX powder (0.5g Ti 3 AlC 2 ) into a mixed solution of 6mol / L hydrochloric acid and 0.8g lithium fluoride and stirred. The above mixed solution was reacted at 35°C for 48h, added water and centrifuged to adjust the pH to about 7, centrifuged (2500r / min) for 1h, and separated to obtain the stripped few-layer MXene suspension.

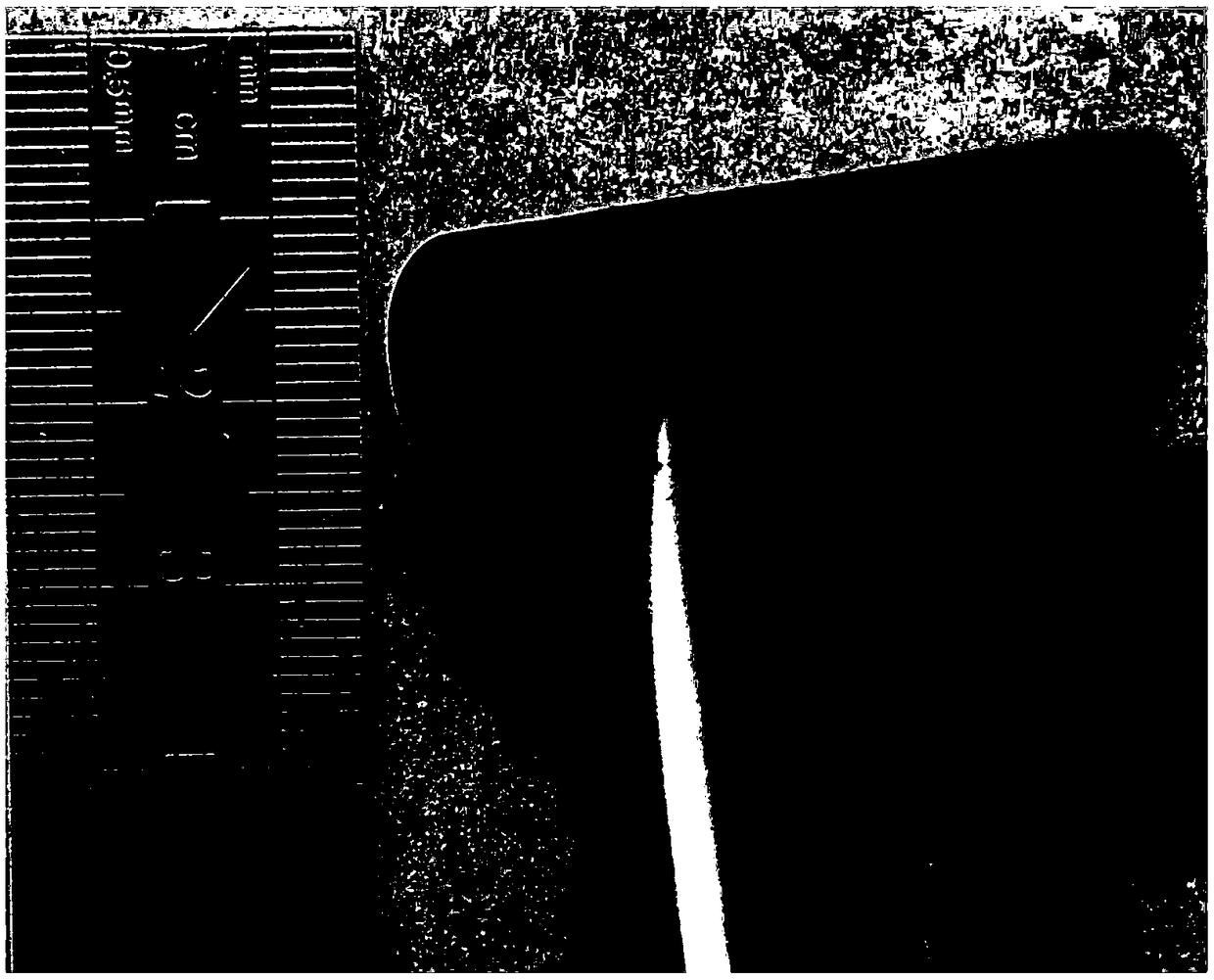

[0070] (2) The MXene suspension was filtered by vacuum filtration, and then vacuum-dried (80°C) to obtain a flexible MXene self-supporting membrane.

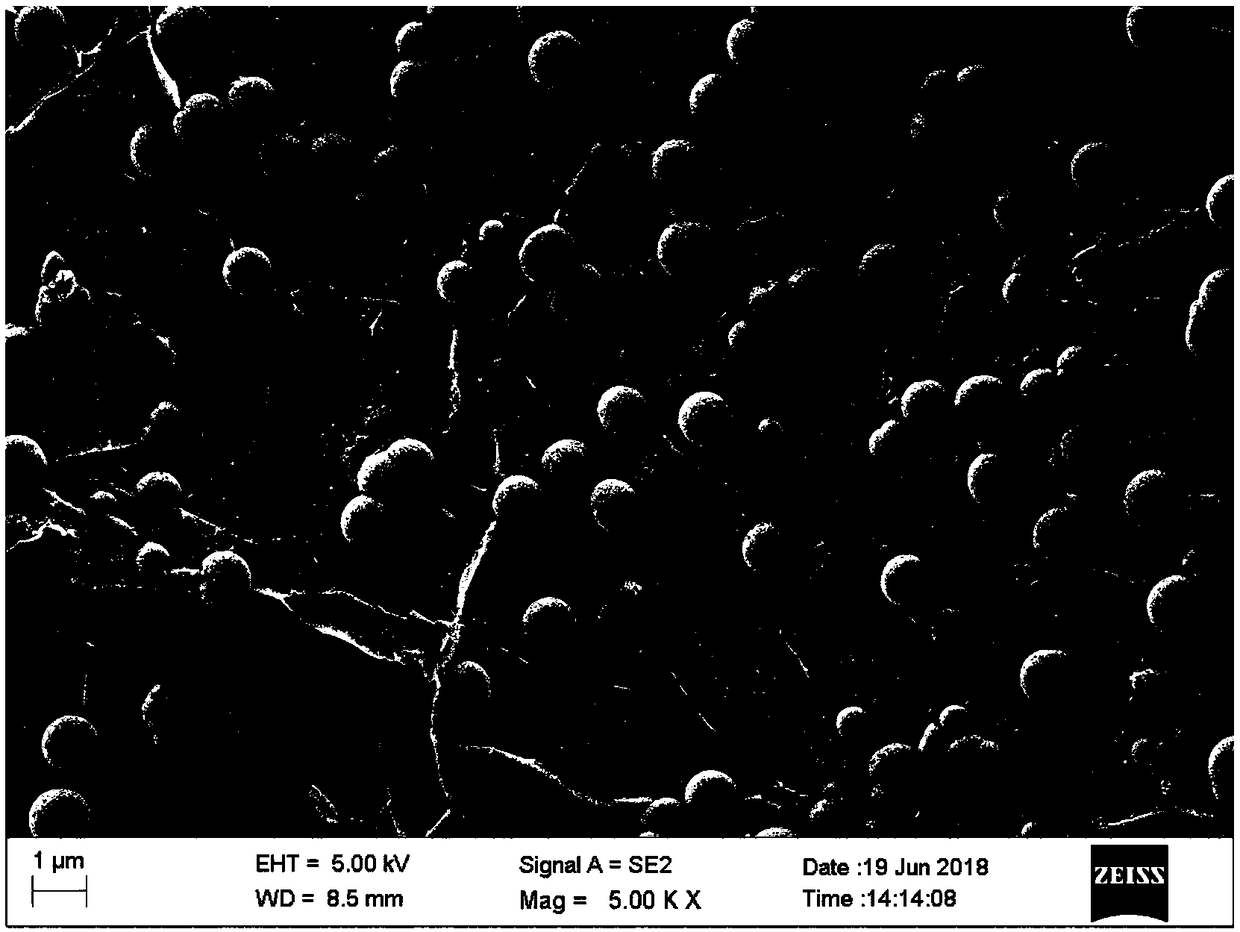

[0071] (3) Put the MXene self-supporting film into the electroplating solution of 20mL ethylene glycol and 1.6g antimony chloride at a constant current of 1mA / cm 2 Electroplating a layer of micro / nano-scale metal microspheres for 40 minutes, and then vacuum drying for 12 hours, you can get flexible Ti 3 C 2 An electrode sheet with Sb particles uniformly distributed on a self-supporting film.

Embodiment 2

[0073] (1) MAX powder (0.5g Ti 3 AlC 2 ) into a mixed solution of 9mol / L sulfuric acid and 0.5g potassium fluoride and stirred. The above mixed solution was reacted at 35°C for 48h, added water and centrifuged to adjust the pH to about 7, centrifuged (3500r / min) for 1h, and separated to obtain the stripped few-layer MXene suspension.

[0074] (2) The MXene suspension was filtered by vacuum filtration, and then vacuum-dried (80°C) to obtain a flexible MXene self-supporting membrane.

[0075] (3) Put the MXene self-supporting membrane into the electroplating solution of 20mL dimethyl sulfoxide and 1.6g antimony chloride at a constant current of 1mA / cm 2 Electroplating for 40 minutes to form a layer of micro / nano-scale metal microspheres, and then vacuum drying for 12 hours to obtain flexible Ti 3 C 2 An electrode sheet with Sb particles uniformly distributed on a self-supporting film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com