Preparation method of lithium fluoride

A lithium fluoride and lithium carbonate technology, applied in the direction of lithium halide, etc., can solve the problems of product agglomeration, affecting the screening process, fine particle size, etc., and achieve the effect of low cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

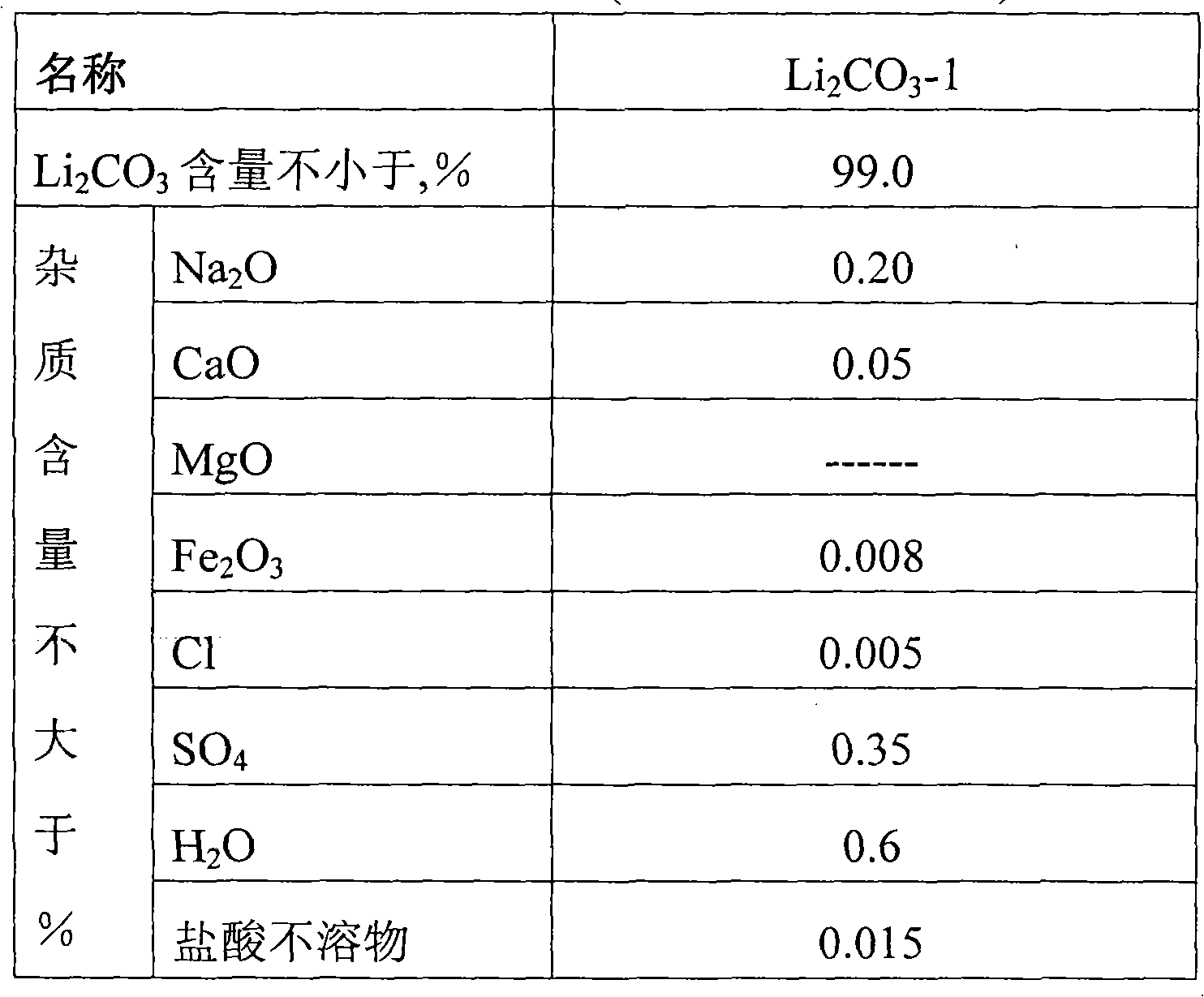

[0021] The raw material lithium carbonate is industrial grade lithium carbonate, wherein the weight content of lithium carbonate is 99.07%, sodium (Na) is 775PPm, magnesium (Mg) is 112PPm, iron (Fe) is 52PPm, potassium (K), aluminum (Al) , copper (Cu) is 20PPm, calcium (Ca) is 221PPm, sulfate (SO 4 2- ) is 1466PPm.

[0022] (1) 1.8M 3 In the stainless steel reaction tower, add 1400L of pure water, turn on carbon dioxide (control the pressure at 0.15Mpa), add 60Kg of industrial grade lithium carbonate, add 0.12Kg oxalic acid, add 0.29Kg barium hydroxide; Dissolve completely, and then filter with a polypropylene plate and frame filter press to obtain a lithium bicarbonate solution.

[0023] (2)5M 3 In the polypropylene reaction tank, add the lithium bicarbonate solution 4000L of step (1), then add 242Kg of hydrofluoric acid, the solution pH=5, keep stirring at 35° C. for 30 minutes, add the lithium hydroxide solution that the weight concentration is 15%, adjust The pH of th...

Embodiment 2

[0026] Raw material lithium carbonate is industrial grade lithium carbonate, wherein, the weight content of lithium carbonate is 99.12%, sodium (Na) content is 855PPm, magnesium (Mg) content is 107PPm, iron (Fe) is 48PPm, potassium (K), aluminum ( Al), copper (Cu) is 20PPm, calcium (Ca) content is 285PPm, sulfate content (SO 4 2- ) is 1521PPm.

[0027] (1) 1.8M 3 In the stainless steel reaction tower, add 1400L of pure water, turn on carbon dioxide (control the pressure at 0.2Mpa), add 60Kg of industrial grade lithium carbonate, add 0.16Kg of oxalic acid, add 0.301Kg of barium hydroxide, and feed carbon dioxide until pH = 8, lithium carbonate Dissolve completely, and then filter with a polypropylene plate and frame filter press to obtain a lithium bicarbonate solution.

[0028] (2)5M 3 In the polypropylene reaction tank, add the lithium bicarbonate solution 4000L of step (1), then add 242.3Kg of hydrofluoric acid, the solution pH=5, keep stirring at 34.3° C. for 34 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com