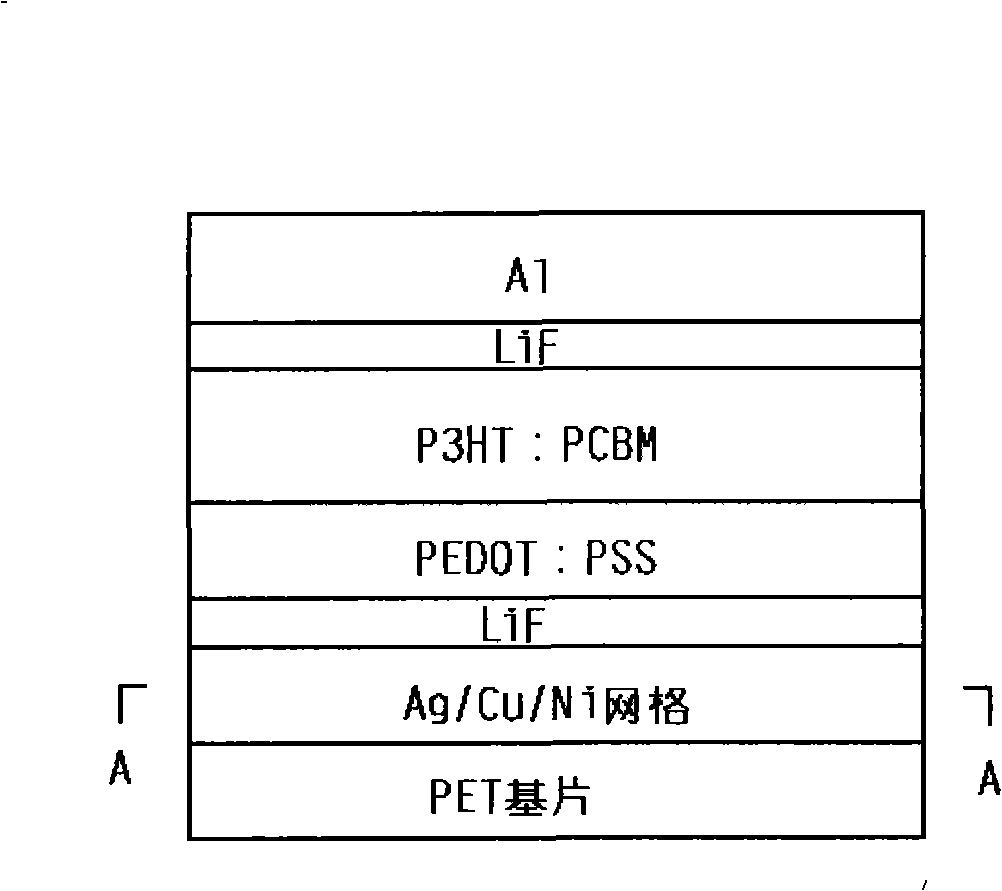

Flexible polymer solar battery of anode layer of metal grid and preparation method

A flexible polymer and solar cell technology, which is applied in the coating process of metal materials, coatings, circuits, etc., can solve the problems of low adhesion, limited space for device improvement efficiency, high anode square resistance, etc., and achieve energy conversion efficiency And performance improvement, improvement of film formation, enhanced balance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

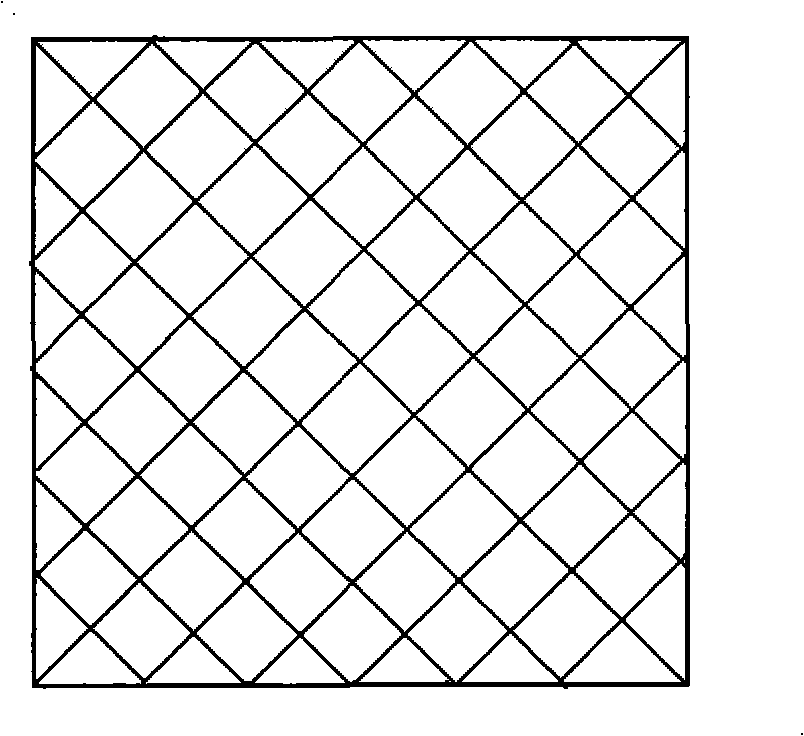

[0030] A. Prepare the grid template: firstly, the ultrafine particle dry board or PCB film is processed by laser exposure and development to make a grid template with a grid pattern, and the line width, line spacing, and density of the grid are adjusted to obtain different grid patterns;

[0031] B. Preparation of metal grids on flexible PET substrates: Print a template with a grid pattern on a silver halide photosensitive film, or scan the grid pattern on a silver halide photosensitive film with a laser; after developing, fixing, and curing , to obtain metal silver grid pattern on the flexible substrate; and then electroless copper plating and electroless nickel plating to obtain silver, copper and nickel grid conductive film anode layer;

[0032] The electroless copper plating on the metal silver grid pattern is to use the electroless plating solution with a pH value of 12.5 at 25°C: copper sulfate 60mM / L, triethanolamine 180mM / L, potassium ferrocyanide 0.002mM / L, copper pla...

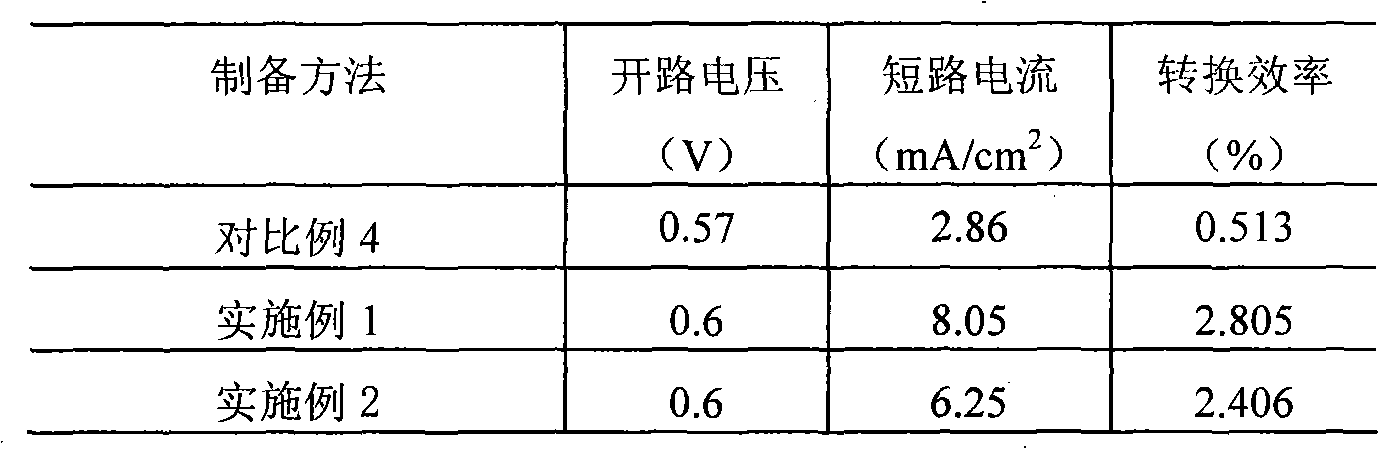

Embodiment 2

[0039] Embodiment 2: The preparation method is the same as that of Embodiment 1, except that the film thickness of the active layer is controlled at 120nm.

Embodiment 3

[0040] Embodiment 3: The preparation method is the same as that of Embodiment 1, except that the film thickness of the active layer is controlled at 90 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com