Method for producing clean diesel by full liquid phase hydrogenation

A technology of liquid-phase hydrogenation and hydrogenation products, which is applied in the fields of hydrogenation treatment process, petroleum industry, and hydrocarbon oil treatment, etc. It can solve the problems of unresolved harmful impurities removal, complex cross-flow reactor structure, and reduced reaction efficiency. , to achieve the effect of ensuring activity stability, low cost, and improving hydrogenation activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

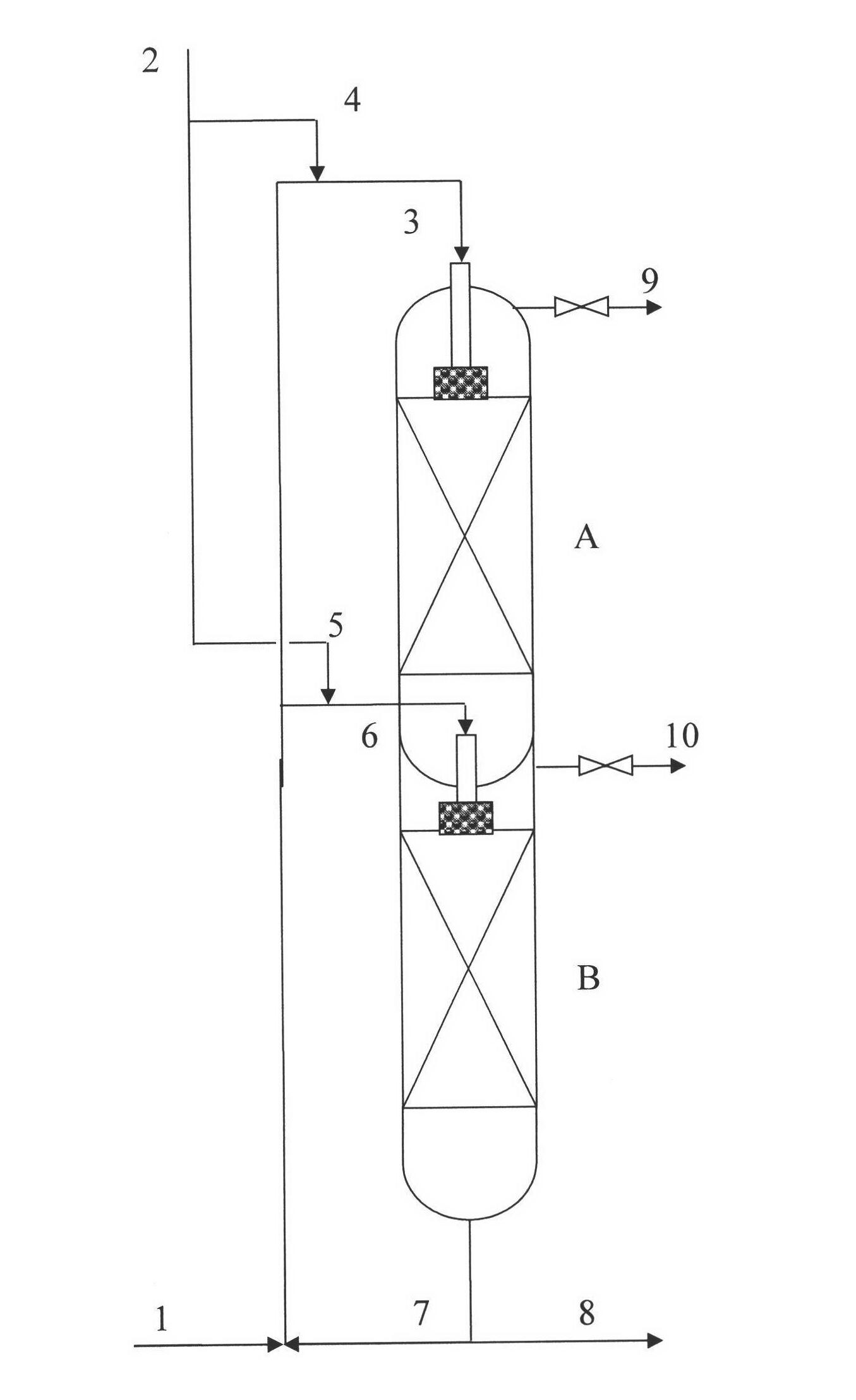

Method used

Image

Examples

Embodiment 1

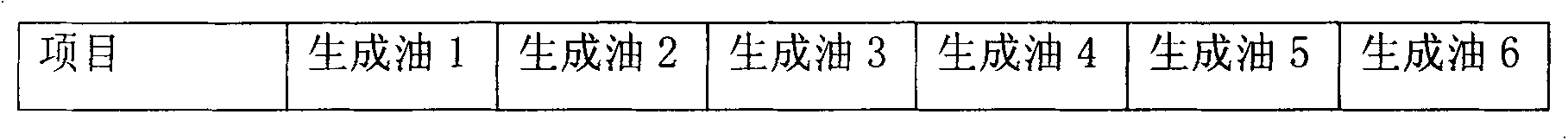

[0032] Two-stage hydrogenation reactors in series are used. The raw materials used are shown in Table 1-1. The catalyst is FH-98 hydrogenation catalyst commonly used in the industry. See Table 1-2 for process conditions and Table 1-3 for properties of refined diesel oil.

[0033] Table 1-1 Properties of Raw Oil

[0034] Oil properties

Raw oil 1

Density (20℃), g / cm 3

0.8922

Distillation range, ℃

128~367

Sulfur, μg / g

8200

Nitrogen, μg / g

630

Actual colloid, mg / 100ml

280

Polycyclic aromatic hydrocarbons, m%

17.4

Total aromatics, m%

32.7

42.2

[0035] Table 1-2 Process conditions

[0036] Process conditions

Example 1

Raw oil

Raw oil 1

reactor

two stages in series

340

Reaction pressure, MPa

6.0

Circulation volume ratio (circulation oil: fresh raw mater...

Embodiment 2

[0041] Two-stage hydrogenation reactors in series are used, the raw materials used are shown in Table 2-1, and the catalyst is FH-98 hydrogenation refining catalyst. See Table 2-2 for process conditions and Table 2-3 for properties of refined diesel oil.

[0042] Table 2-1 Properties of Raw Oil

[0043] Oil properties

Raw oil 2

Density (20℃), g / cm 3

0.8935

Distillation range, ℃

164~365

Sulfur, μg / g

3200

Nitrogen, μg / g

2040

Actual colloid, mg / 100ml

182

Total aromatics, m%

37.2

41

[0044] Table 2-2 Process conditions

[0045] Process conditions

Example 2

Raw oil

Raw oil 2

reactor

two stages in series

360

Reaction pressure, MPa

6.5

Circulation volume ratio (circulation oil: fresh raw material)

2.5

1st / 2nd volumetric space velocity, h -1

4...

Embodiment 3

[0049] Three-stage series hydrogenation reactors are used. The raw materials used are shown in Table 3-1. The catalysts are FH-98 hydrofinishing catalyst and FC-12 hydrocracking catalyst commonly used in the industry. The two catalysts are evenly loaded in each reactor. . See Table 3-2 for process conditions and Table 3-3 for properties of refined diesel oil.

[0050] Table 3-1 Properties of Raw Oil

[0051] Oil properties

Raw oil 2

Density (20℃), g / cm 3

0.9135

Distillation range, ℃

197~465

Sulfur, μg / g

4200

Nitrogen, μg / g

2940

Actual colloid, mg / 100mL

262

Total aromatics, m%

39.2

[0052] Table 3-2 Process conditions

[0053] Process conditions

Example 2

Raw oil

Raw oil 2

reactor

two stages in series

370

Reaction pressure, MPa

6.5

Circulation volume ratio (circulation oil: fresh ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com