Method for producing clean fuels through low-cost hydrogenation

A technology for hydrogenation products and hydrotreating, applied in refining to remove heteroatoms, etc., can solve problems such as reducing reaction efficiency and failing to solve the removal of harmful impurities, reducing temperature rise, maintaining activity stability, and operating flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

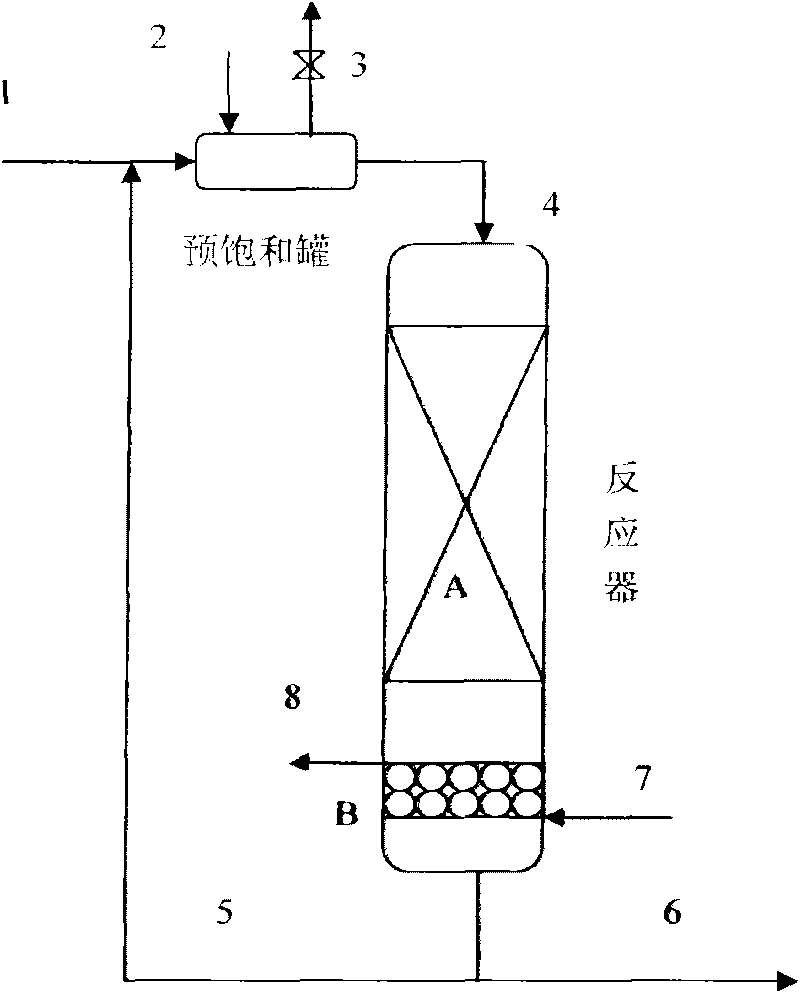

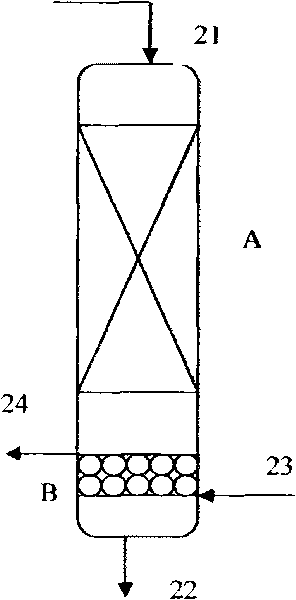

Method used

Image

Examples

Embodiment 1

[0031] A single-stage cross-flow reactor is used, the raw materials used are shown in Table 1-1, and the catalyst is FH-UDS hydrorefining catalyst. The composition and quality index of FH-UDS catalyst are shown in Table 1-2, the process conditions are shown in Table 1-3, and the properties of refined diesel oil are shown in Table 1-4.

[0032] Table 1-1. Properties of raw oil

[0033]

[0034] Table 1-2, the composition and quality index of the catalyst

[0035]

[0036] Table 1-3, process conditions

[0037] Process conditions

Example 1

Raw oil

Raw oil 1

reactor

Reverse

[0038] Process conditions

Example 1

340

Reaction pressure, MPa

4.0

Circulation volume ratio

(Circulating oil: fresh raw material)

2

Total volumetric airspeed, h -1

4.0

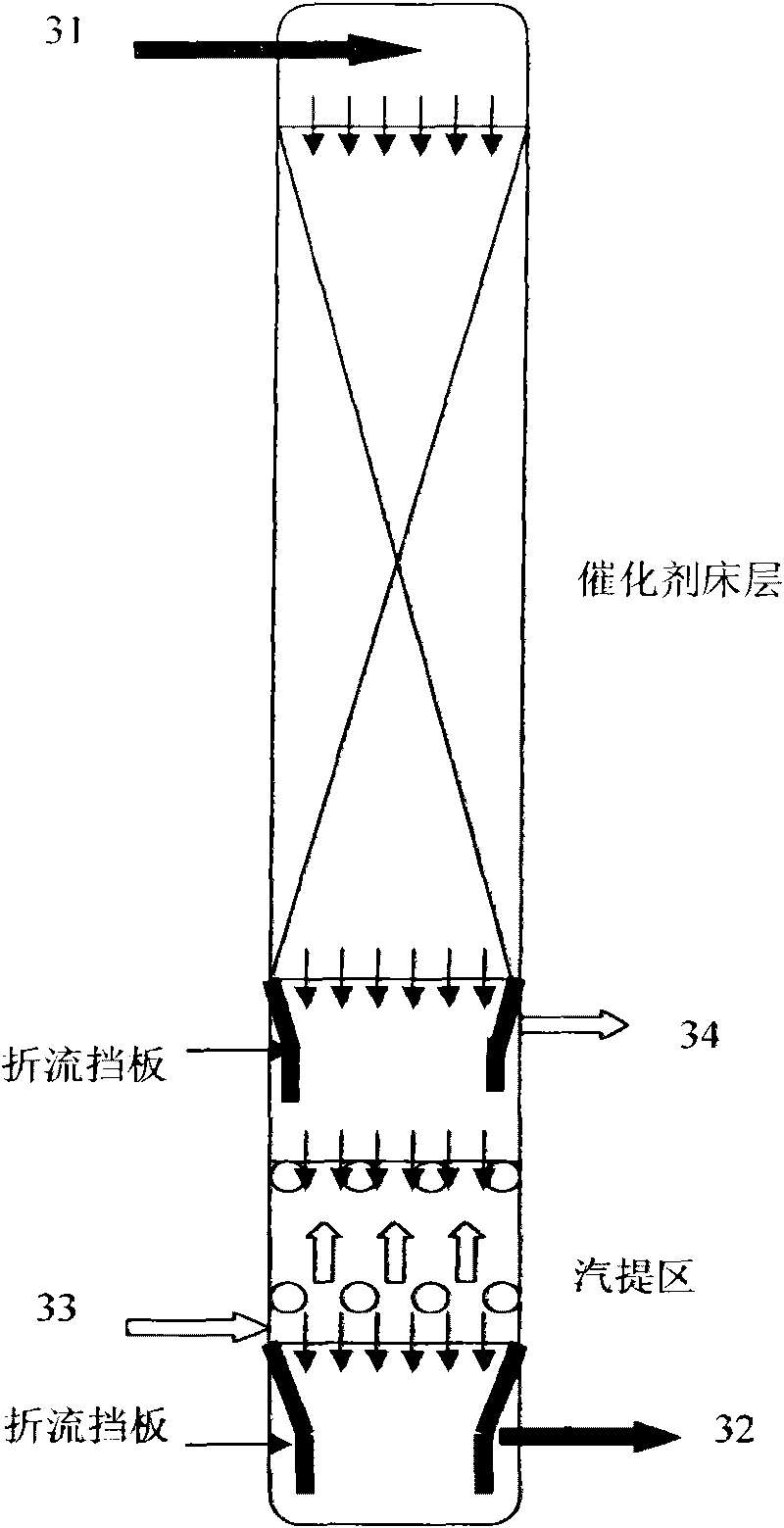

[0039] The process conditions of the cross-flow stripping zone are: nitrogen is used as the stripping gas, the pressure is 4.0 MPa, the temperature is 290°C, and the gas-oil volume ratio is 4...

Embodiment 2

[0043] A two-stage cross-flow reactor is used, the raw materials used are shown in Table 2-1, and the catalyst is FH-UDS hydrofining catalyst. The process conditions are shown in Table 2-2, and the properties of refined diesel oil are shown in Table 2-3.

[0044] Table 2-1. Properties of raw oil

[0045]

[0046] Table 2-2. Process conditions

[0047] Process conditions

Example 2

Raw oil

Raw oil 2

reactor

Two-stage cross-flow reactor

350

Reaction pressure, MPa

6.0

Circulation volume ratio

(Circulating oil: fresh raw material)

1.5

Total volumetric airspeed, h -1

5.0

[0048] The process conditions of the first-stage cross-flow stripping zone are: hydrogen is used as the stripping gas, the pressure is 6.0MPa, the temperature is 350°C, and the hydrogen-to-oil volume ratio is 120:1; the process conditions of the second-stage cross-flow stripping zone are: Using hydrogen as the stripping gas, the pressure is 6.0MPa, the temperature is 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com