Treatment system and treatment method for removing hydrogen sulfide from acid gas

A sour gas and treatment system technology, applied in chemical instruments and methods, separation methods, chemical recovery, etc., can solve problems such as inability to be measured, small operating flexibility, and affecting system operation, so as to save investment and construction period, and achieve good operation The effect of flexibility and simplified equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

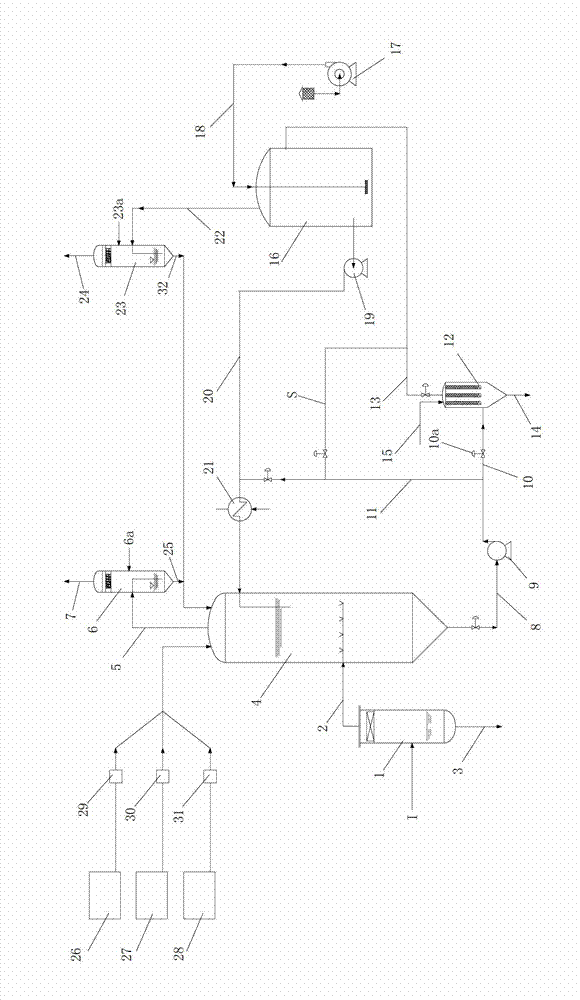

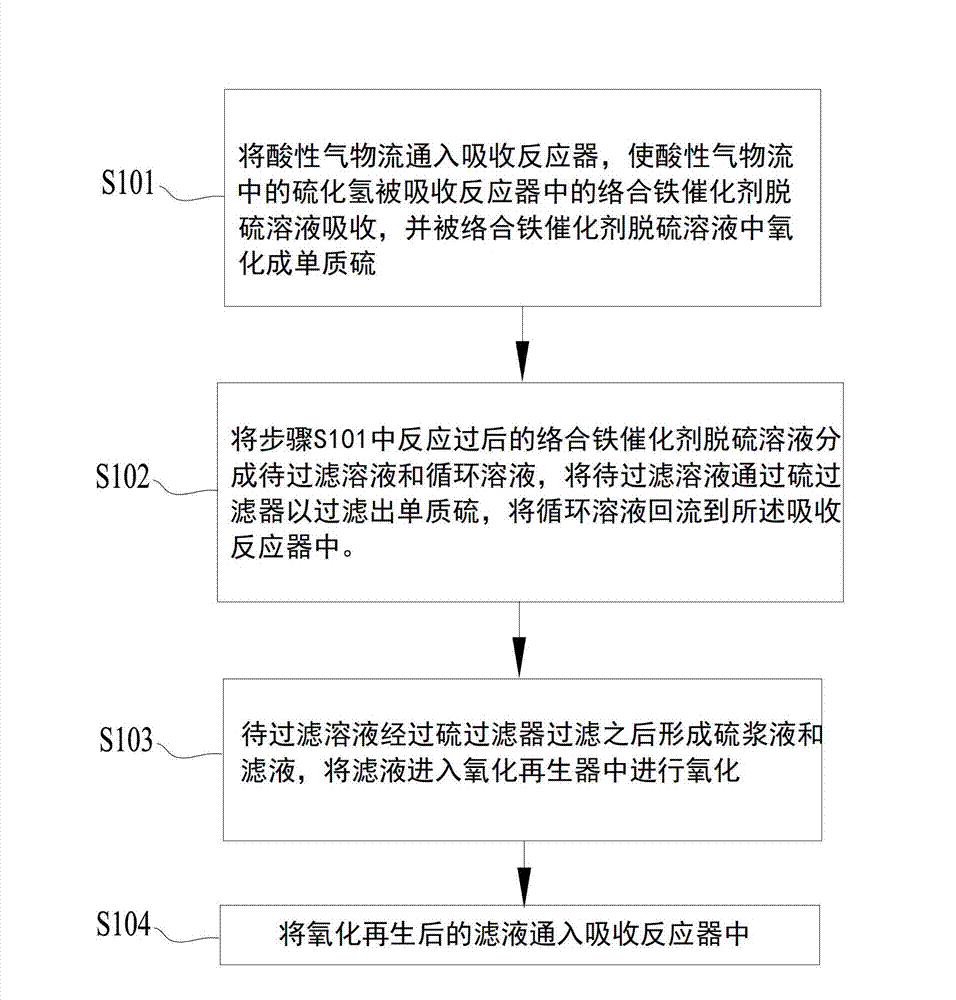

[0049] figure 1 It is a schematic diagram of an acid gas removal hydrogen sulfide treatment system according to an embodiment of the present invention. Such as figure 1 As shown, in an embodiment of the present invention, the acid gas removal hydrogen sulfide treatment system includes a waste gas pretreatment unit, an absorption reaction unit, a sulfur filtration unit, a solution regeneration unit, a temperature control unit, a chemical delivery unit and a tail gas treatment unit.

[0050] The exhaust gas pretreatment unit is used to pretreat the acid gas passed in to remove impurities; the absorption reaction unit has a complex iron catalyst desulfurization solution, which is used to absorb and oxidize hydrogen sulfide in the acid gas passed into it into a simple substance Sulfur; the sulfur filtration unit is used to filter the elemental sulfur formed by oxidation; the solution regeneration unit is used to oxidize and regenerate the complex iron catalyst desulfurization sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com