Liquid oxygen and liquid nitrogen preparation device and method

A liquid oxygen and liquid nitrogen technology, applied in the field of liquid oxygen and liquid nitrogen production devices, can solve problems such as increasing the difficulty of operation, and achieve the effects of high production efficiency, high product extraction rate and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

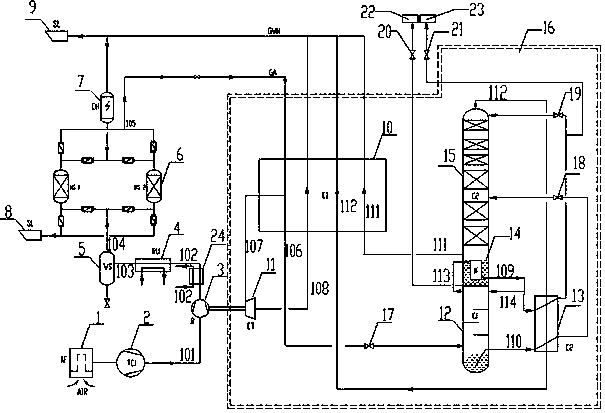

[0024] A device for producing liquid oxygen and liquid nitrogen, such as figure 1As shown, it includes an air compression system, a pre-cooling system, a purification system and a cold box 16, and the air compression system includes a self-cleaning air filter 1 and an air compressor 2 connected to the self-cleaning air filter. Cold system comprises cooler 24 and air-conditioning unit 4, and described purification system comprises molecular sieve adsorber 6, electric heater 7, first muffler 8 and second muffler 9, and electric heater heats the dirty nitrogen that cold box comes over to 175 After ℃, it is sent to the molecular sieve adsorber for molecular sieve regeneration, and the silencer plays the role of eliminating noise for the venting of dirty nitrogen and nitrogen. The cold box includes a main heat exchanger 10, an expansion end 11 of a turboexpander and a fractionation tower; The air compressor is connected with the supercharged end 3 of a turboexpander through the fir...

Embodiment 2

[0028] A liquid oxygen and liquid nitrogen production method, using a liquid oxygen and liquid nitrogen production device, the device is the first embodiment of the liquid oxygen and liquid nitrogen production device, which will not be repeated here. The method includes:

[0029] 1) The raw material of this device is air. The air first passes through the self-cleaning air filter 1 to filter out impurities and then enters the air compressor 2. The compressed gas pressure is 0.6~1.0MPa and the temperature is 40°C. The compressed gas is directly Enter the booster end 3 of the turbo expander to pressurize. After the pressurization, it is cooled to 40°C by the cooler 24 and then enters the air-conditioning unit 4 to be cooled again to 5~8°C. The cooled gas is separated by the separator 5 to remove free After the water enters the molecular sieve adsorber for adsorption, the gas enters the cold box 16 after absorbing water, carbon dioxide and some hydrocarbons through the adsorber, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com