Staged-pressurization gasification reaction device for dry pulverized coal and gasification method thereof

A pressurized gasification and reaction device technology, which is applied to the gasification of granular/powdered fuels, the manufacture of combustible gases, and the petroleum industry. and other issues, to achieve the effect of enhancing operation controllability and reliability, reducing size and footprint, and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

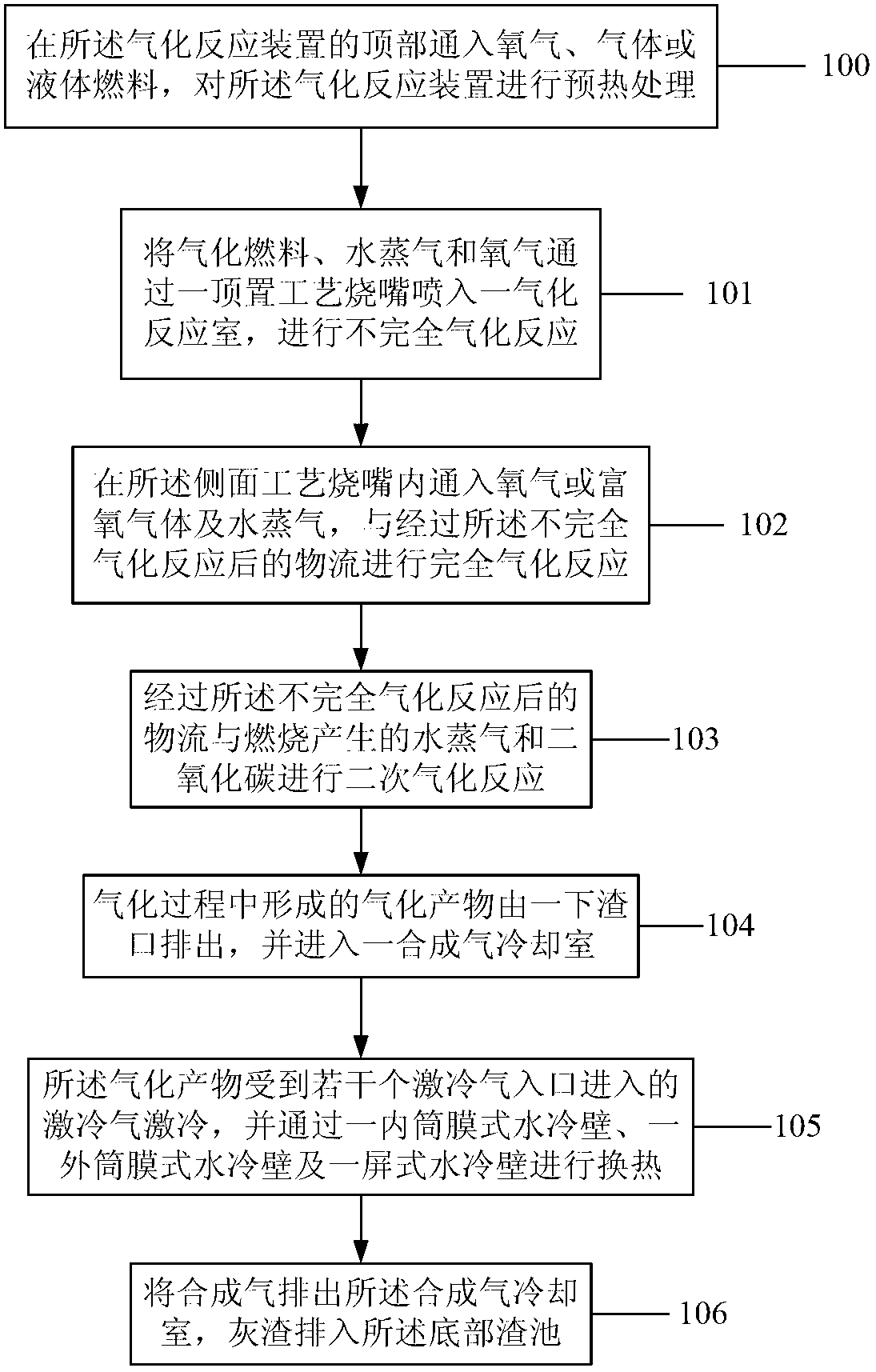

[0063] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

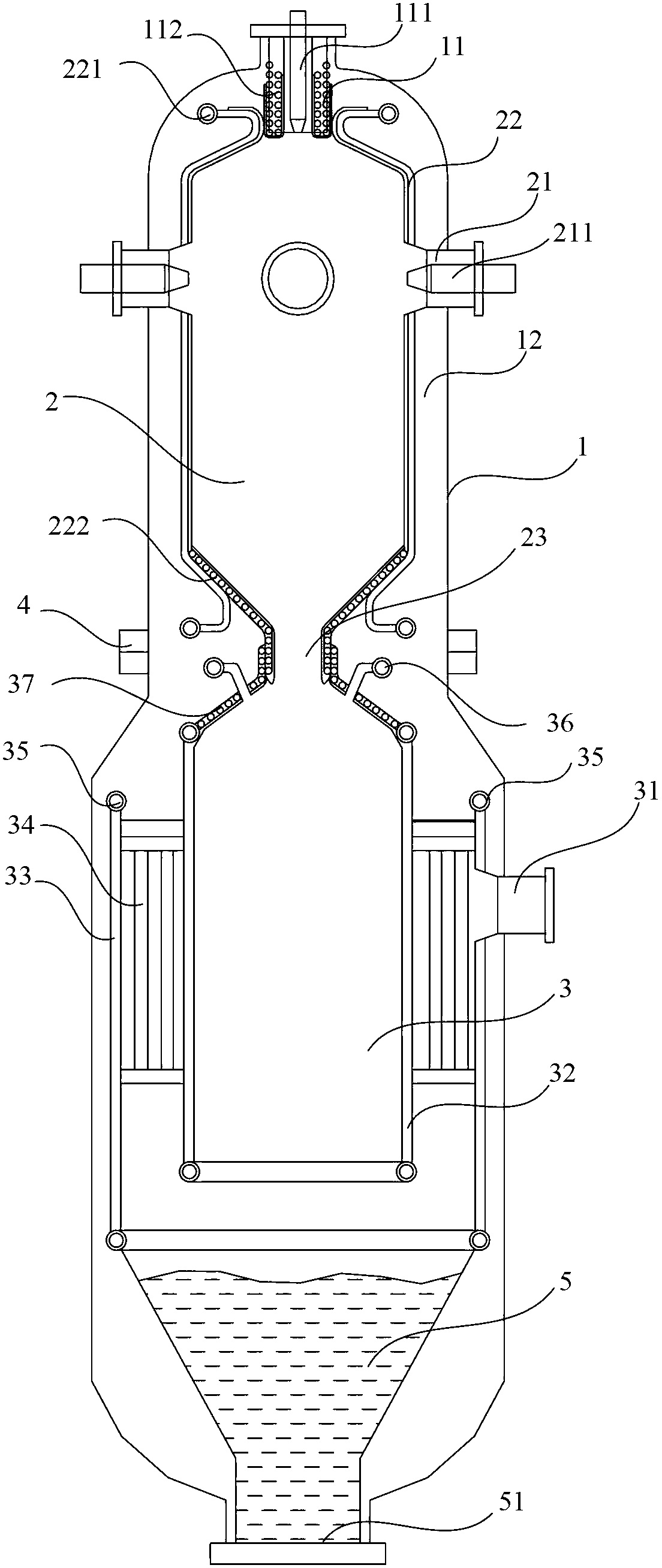

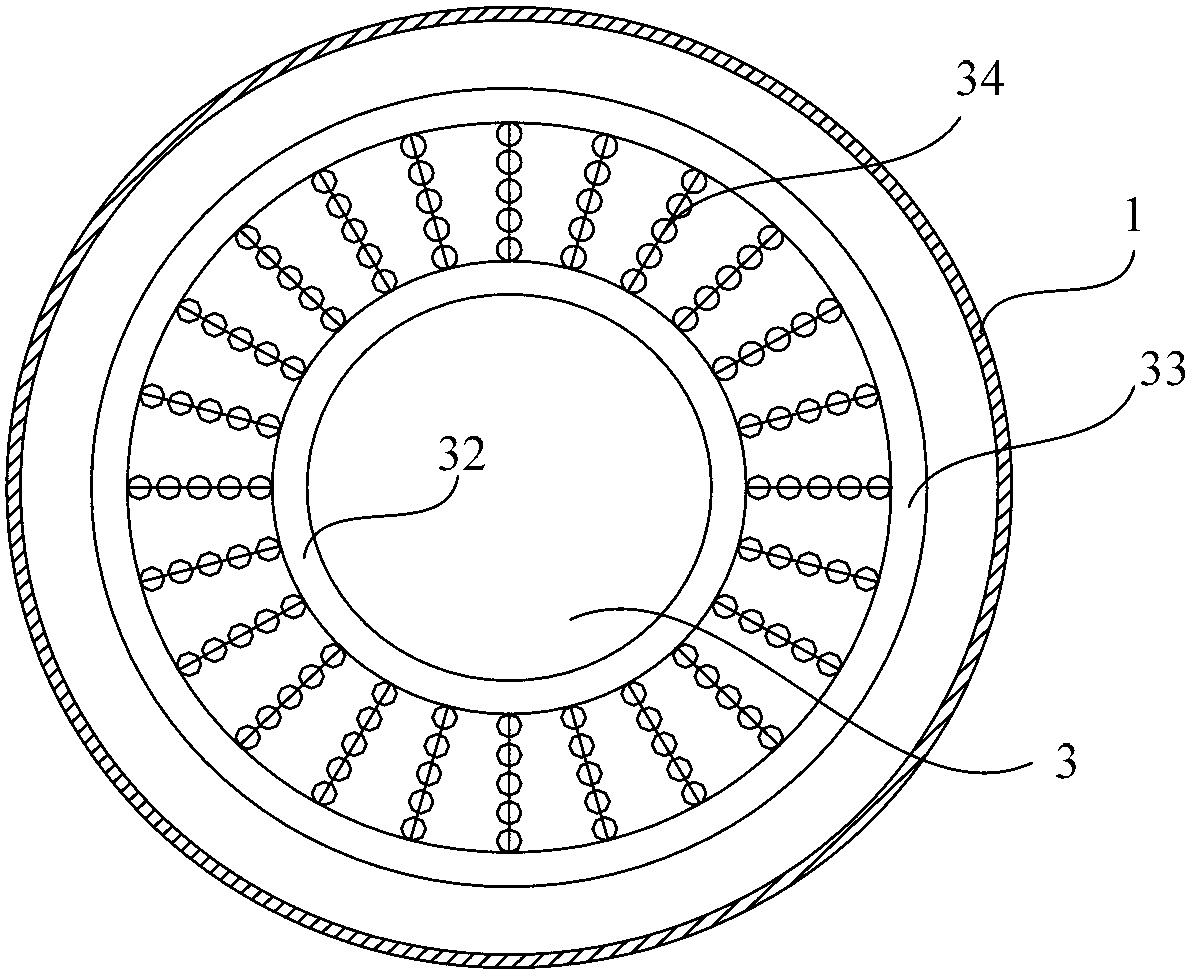

[0064] Such as Figure 1-2 As shown, the dry coal powder graded pressurized gasification reaction device of the present invention is set as a vertical cylinder in this embodiment, which includes a furnace shell 1, and a furnace shell 1 is coaxially arranged from top to bottom. Gasification reaction chamber 2 , a synthesis gas cooling chamber 3 and a bottom slag pool 5 .

[0065] A first burner chamber 11 is arranged on the top of the gasification reaction chamber 2 , and an overhead process burner 111 is arranged in the first burner chamber 11 . At the same time, a layer of second burner chambers 21 is arranged on the upper side of the gasification reaction chamber 2 along the circumferential direction, and a side process burner 211 is arranged in each second burner chamber 21 . One la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com