Melt spinning device

A melt spinning, spinning box technology, applied in melt spinning, textile and papermaking, filament/thread forming, etc., to reduce shaking and improve operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

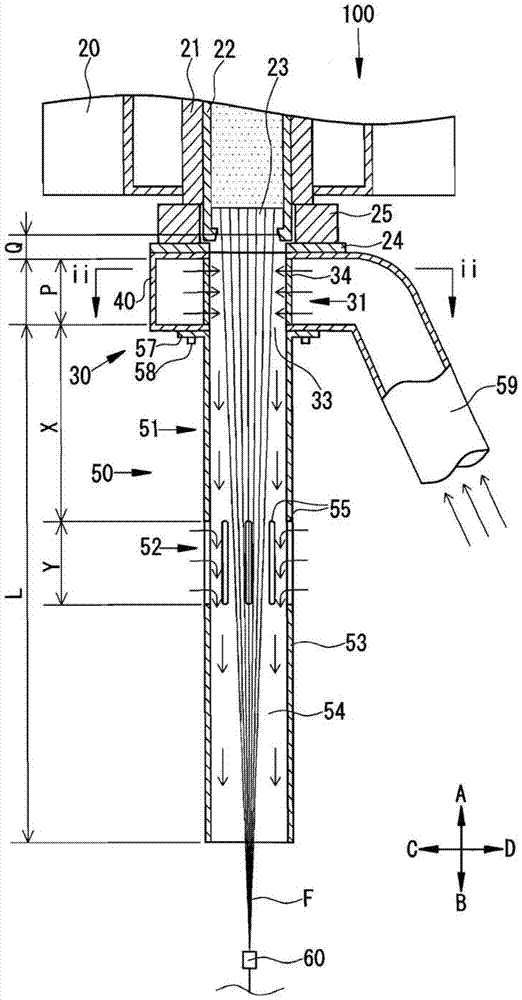

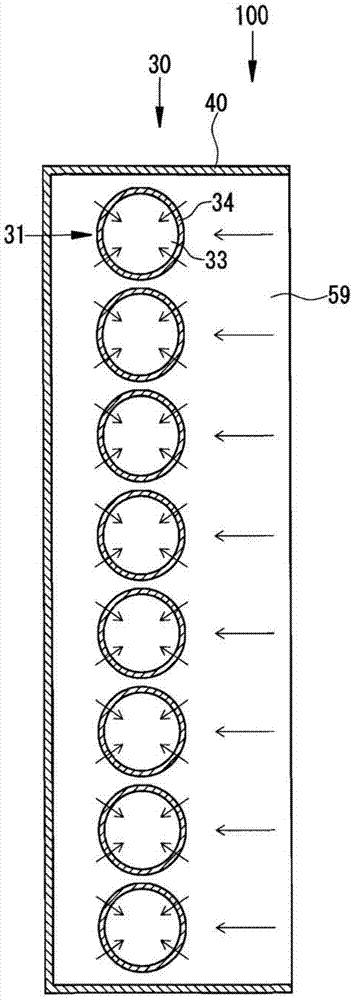

[0041] use figure 1 and figure 2The melt spinning apparatus 100 of Example 1 of the present invention will be described. In the following description, the figure 1 The direction above the diagram (arrow A) in the figure is taken as up, and the direction below the diagram (arrow B) is taken as down. exist figure 2 The side where the duct 59 is provided is defined as the rear side of the melt spinning apparatus 100 , and the opposite side is defined as the front side of the melt spinning apparatus 100 . Let the direction from the rear side to the front side (arrow C) be the first direction, and let the direction from the front side to the rear side (arrow D) be the second direction.

[0042] The melt spinning device 100 of this embodiment is a melt spinning device suitable for producing a high-quality yarn Y with a total fineness of 75 de or more and a single filament fineness of 2 dpf or more. Yarn Y with a total fineness of more than 75de and a single fiber fineness of ...

Embodiment 2

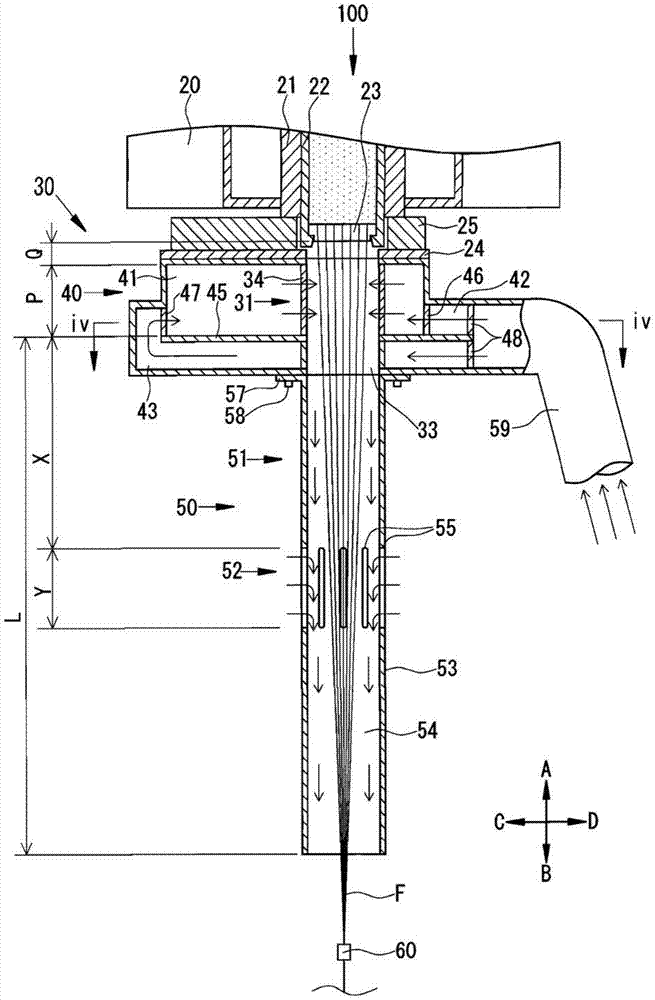

[0062] Next, use image 3 and Figure 4 The melt spinning apparatus 100 of Example 2 of the present invention will be described. The melt spinning apparatus 100 of this embodiment is different from the first embodiment in that cooling air is supplied from the front and rear of the cooling cylinder 31 . The same reference numerals are assigned to the same parts as those in Embodiment 1, and detailed description thereof will be omitted.

[0063] Such as image 3 As shown, a plurality of component housings 21 are disposed on the spinning beam 20 . A plurality of component housings 21 are arranged in a zigzag shape. A spin pack 22 is disposed in each pack case 21 , and a plurality of spinnerets 23 for spinning single fibers F are disposed at the lower end of the spin pack 22 .

[0064] The cooling device 30 mainly includes a cooling tube 31 , a cooling air supply box 40 , and an extension tube 50 . The CIQ is mainly composed of a cooling cylinder 31 and a cooling air supply ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com