Coal tar full-fraction hydrogenation method for coupling slurry bed and static bed

A technology for coal tar and full distillate, applied in the field of coal chemical industry, can solve the problems of complex multi-stage hydrotreating process and high input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

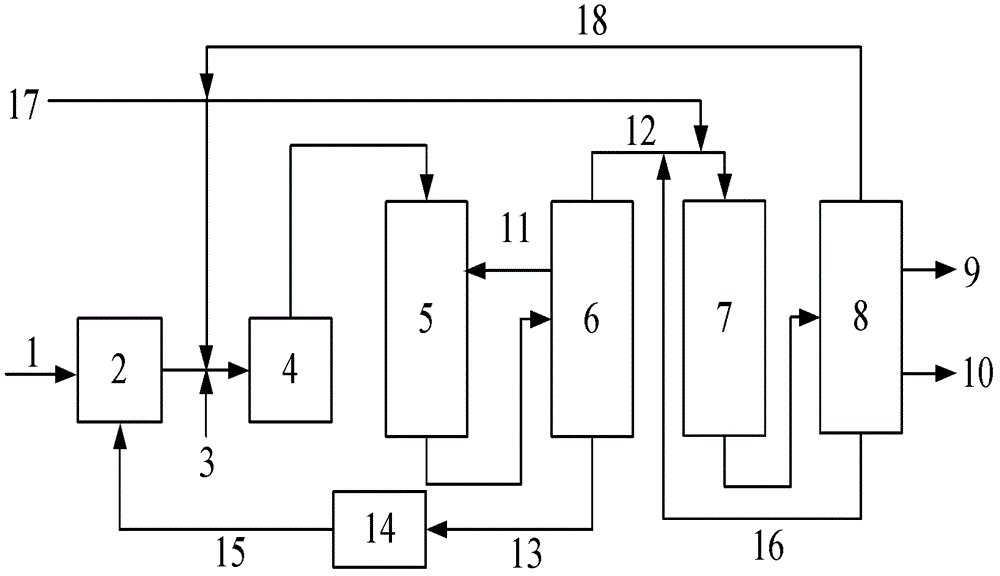

Method used

Image

Examples

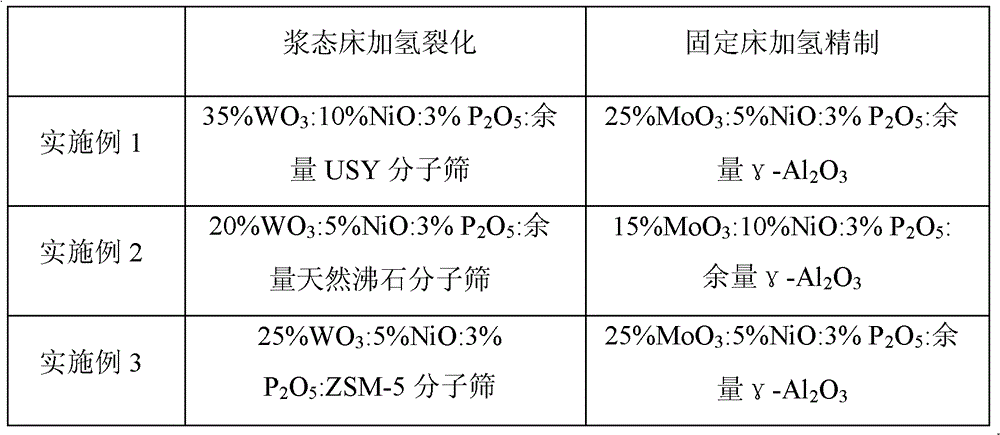

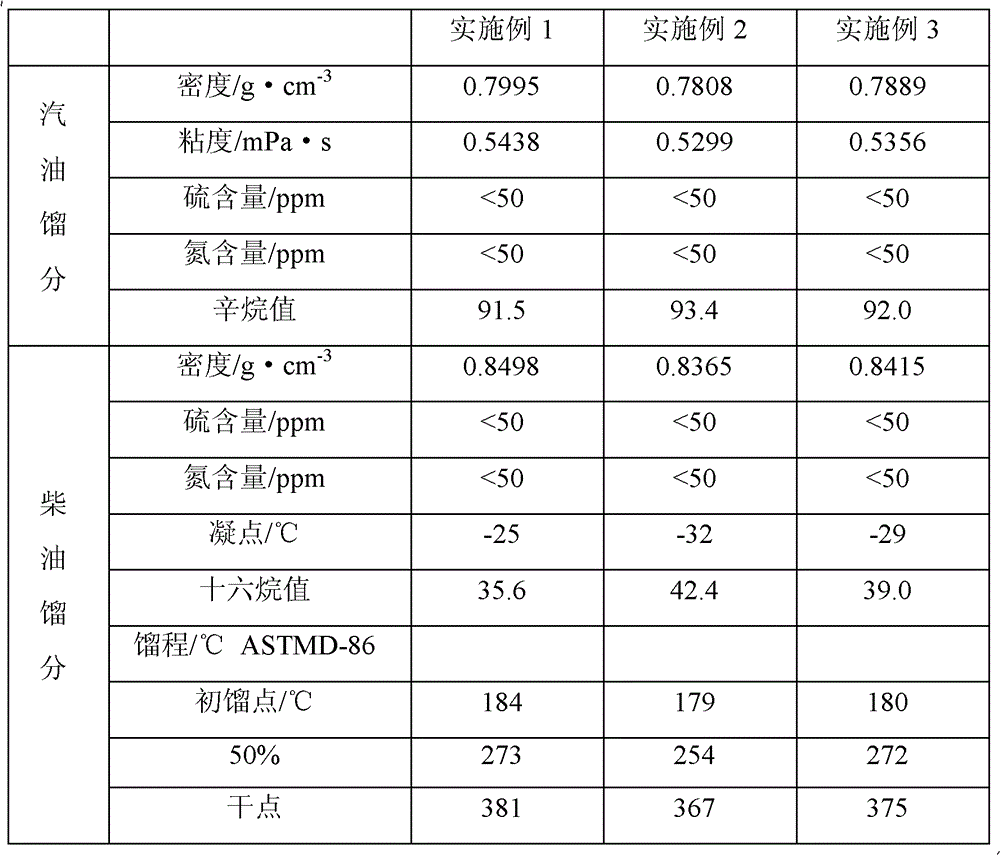

Embodiment 1

[0022] The whole distillate of a kind of high-temperature coal tar is used as the raw material, which is recorded as 1# raw material oil, and its properties are shown in Table 1. It is pretreated to remove water and mechanical impurities, mixed with the hydrocracking catalyst evenly into the slurry bed reactor, and hydrocracked The reaction conditions are listed in Table 3. The initial product after hydrocracking enters the fractionation tower, and the light fraction enters the rear stage fixed-bed reactor for hydrofining. This fraction accounts for about 15wt%, and about 65wt% of the middle distillate is recycled back to the slurry bed The reactor continues to hydrocrack, and about 20 wt% of the heavy fraction enters the raw material storage tank after filtering to remove part of the catalyst and coke generated during the reaction, and the recycling rate of the catalyst is about 80%. Table 3 shows the reaction conditions for fixed-bed hydrotreating of light distillates. The p...

Embodiment 2

[0024] The mixture of high-temperature coal tar phenol oil fraction and medium-temperature coal tar whole fraction oil is used as raw material oil, which is recorded as 2# raw material oil, and its properties are shown in Table 1. Pretreatment removes water and mechanical impurities, and the raw material is mixed with hydrocracking catalyst Evenly enter the slurry bed reactor, the hydrocracking reaction conditions are listed in Table 3, the primary product after hydrocracking enters the fractionation tower, and the light fraction enters the rear stage fixed bed reactor for hydrorefining, and this fraction accounts for about 45wt%. , about 50wt% of the middle distillate is recycled back to the slurry bed reactor to continue hydrocracking, and about 5wt% of the heavy fraction enters the raw material storage tank after filtering to remove part of the catalyst and the coke produced in the reaction process. The recycling rate of the catalyst is about 90%. The light fractions contin...

Embodiment 3

[0026] The mixture of low-temperature coal tar whole distillate oil and residual oil is used as raw material oil, recorded as 3# raw material oil, its properties are shown in Table 1, pre-treated to remove water and mechanical impurities, mixed evenly with hydrocracking catalyst and entered into slurry bed reaction The hydrocracking reaction conditions are listed in Table 3. The initial product after hydrocracking enters the fractionation tower, and the light fraction enters the rear fixed-bed reactor for hydrofining. This part of the fraction accounts for about 30wt%, and the middle distillate is about 55wt%. Circulate back to the slurry bed reactor to continue hydrocracking. About 15wt% of the heavy fraction enters the raw material storage tank after filtering to remove part of the catalyst and coke generated during the reaction. The recycling rate of the catalyst is about 85%. The hydrofining reaction conditions are listed in Table 3. The products are cut into gasoline and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com