Nucleation of Aluminum Nitride on a Silicon Substrate Using an Ammonia Preflow

a technology of aluminum nitride and silicon substrate, which is applied in the direction of crystal growth process, polycrystalline material growth, chemically reactive gas growth, etc., can solve the problems of poor quality of epitaxial gan layers, gan is not well suited for epitaxial growth directly on a silicon substrate, and the current attempts to grow high quality epitaxial gan layers on silicon substrates have not been entirely successful

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]Reference will now be made in detail to some embodiments of the invention, examples of which are illustrated in the accompanying drawings.

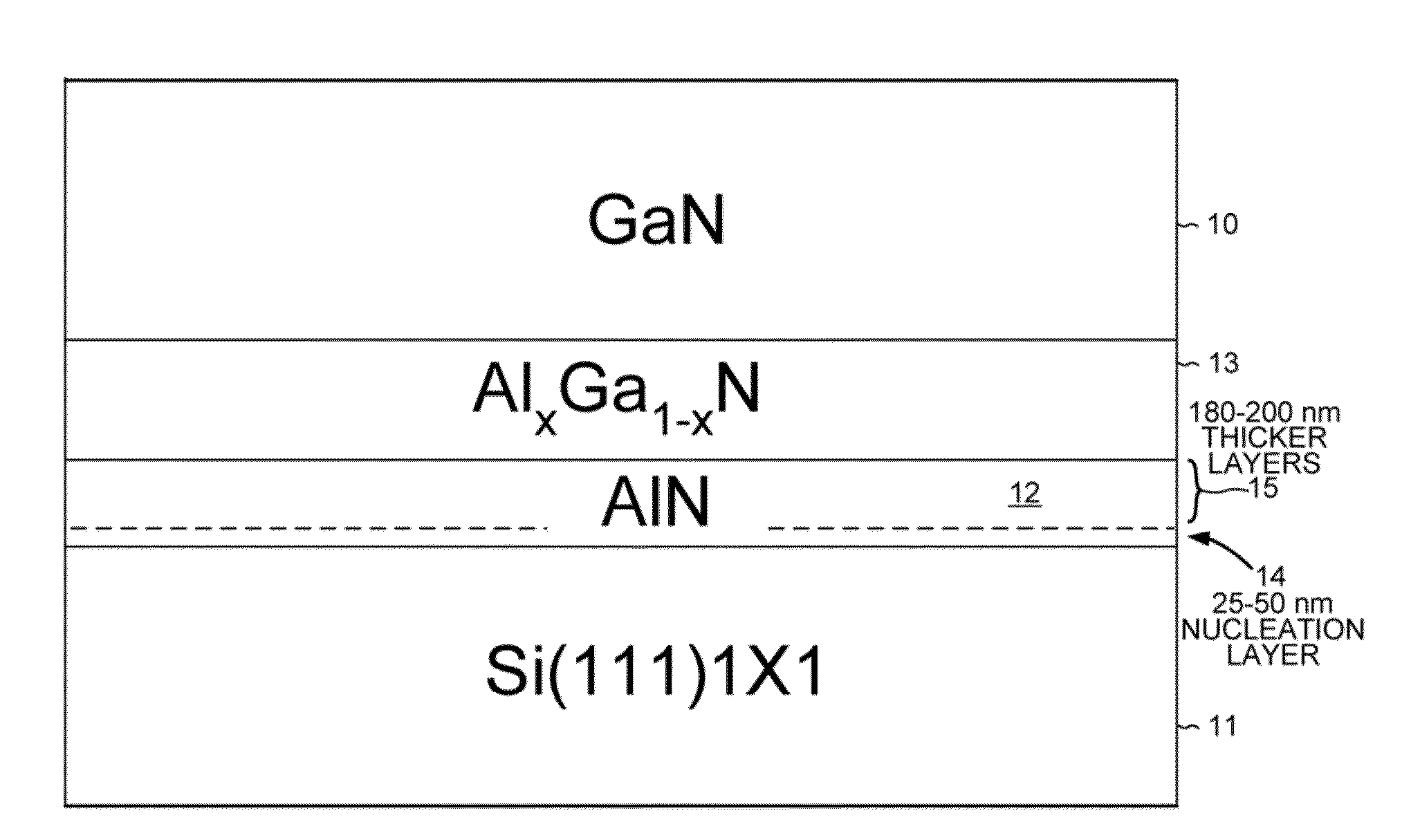

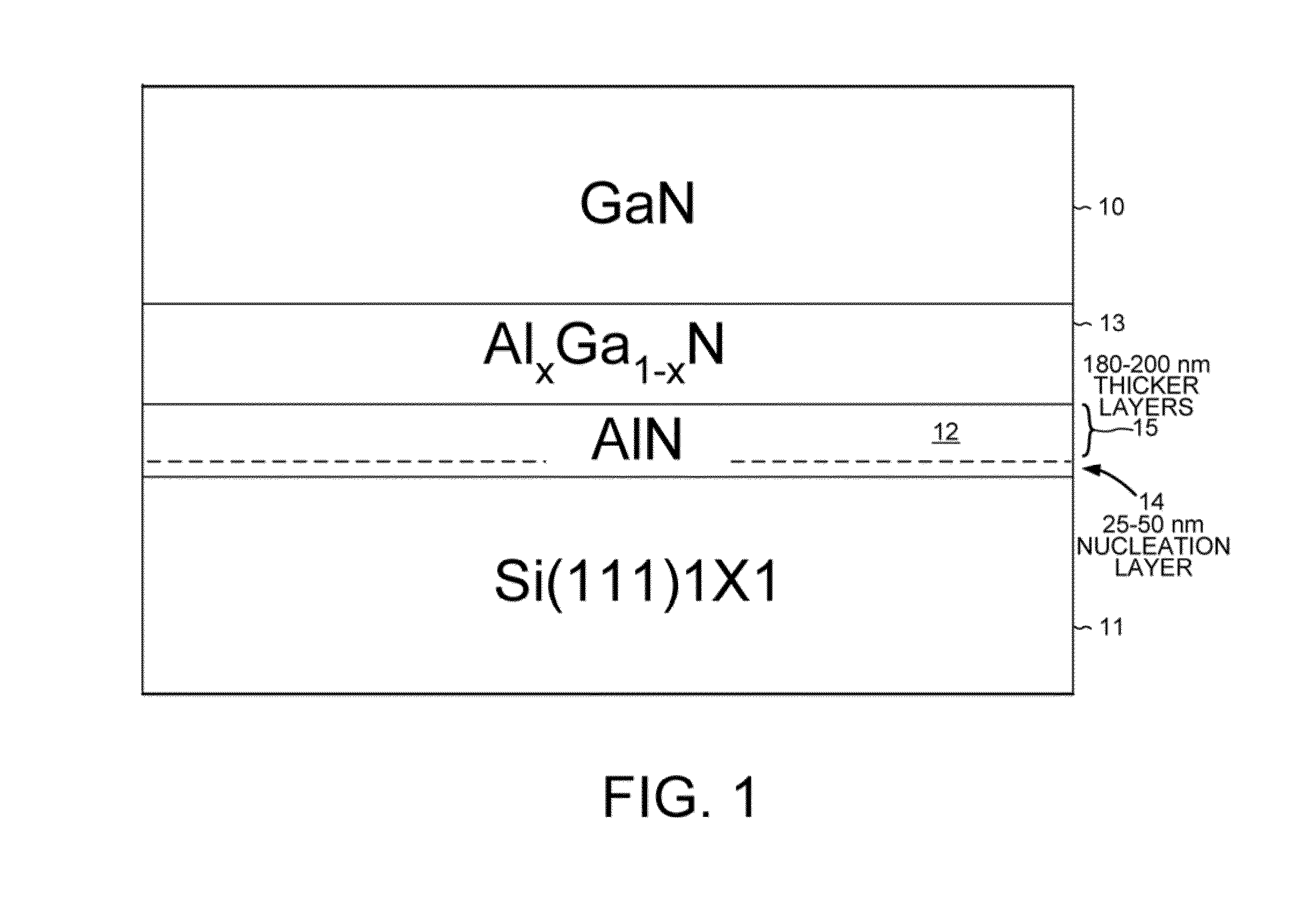

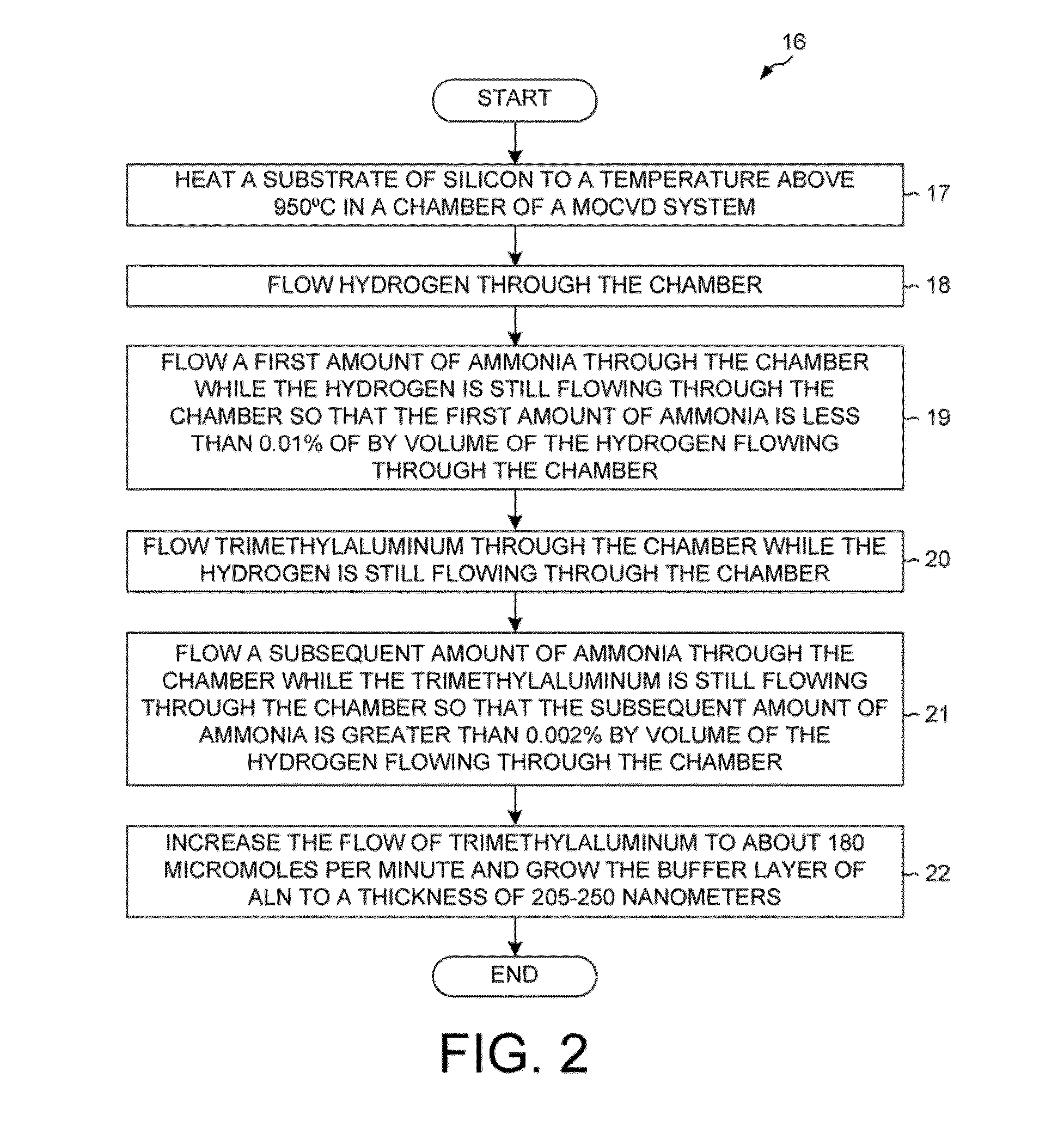

[0025]FIG. 1 is a schematic diagram showing the growth of a single crystal GaN film 10 on buffer layers over a silicon substrate 11. A buffer layer of aluminum nitride (AlN) 12 is first grown on the silicon substrate 11. Then higher buffer of layers of aluminum gallium nitride (AlxGa1-xN) 13 are grown over the AlN layer 12. Finally, the GaN layer 10 is grown over the top layer of aluminum gallium nitride 13. In some embodiments, the GaN layer includes several sublayers. The buffer layer of AlN 12 is made up of a lower initial nucleation layer 14 and thicker upper layers 15.

[0026]There are several reasons for first growing buffer layers on a silicon substrate before the gallium nitride (GaN) layer 10 is grown. First, meltback etching of the silicon substrate 11 by gallium occurs if the gallium is allowed to react directly with the silicon sub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com