Integrated metal-graphite composite bipolar plate fuel cell light electric stack and manufacturing method thereof

A fuel cell and bipolar plate technology, which is applied to fuel cells, fuel cell grouping, battery electrodes, etc., can solve the problems of affecting anode gas diffusion, insufficient stack strength, and damage to membrane electrode materials, so as to improve the overall output performance, The effect of uniform gas diffusion and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

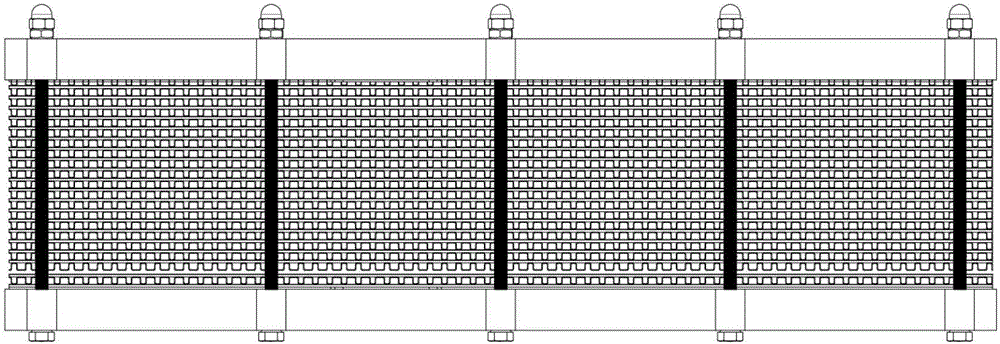

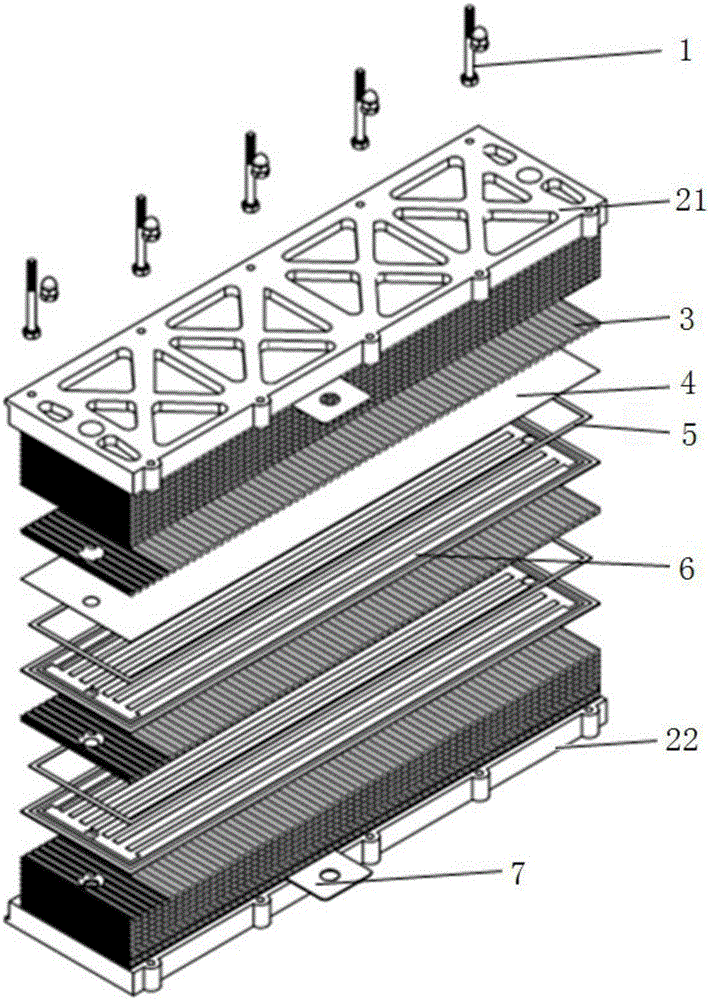

[0037] figure 1 Shown is an integrated metal-graphite composite bipolar plate fuel cell light stack provided in this embodiment, which mainly includes an integrated metal-graphite composite bipolar plate 11, a membrane electrode 4, a gasket 5, and a fuel gas supply pipeline (not shown in the figure), mining plate 7, upper end plate 21, lower end plate 22 and screw rod 1 for fastening.

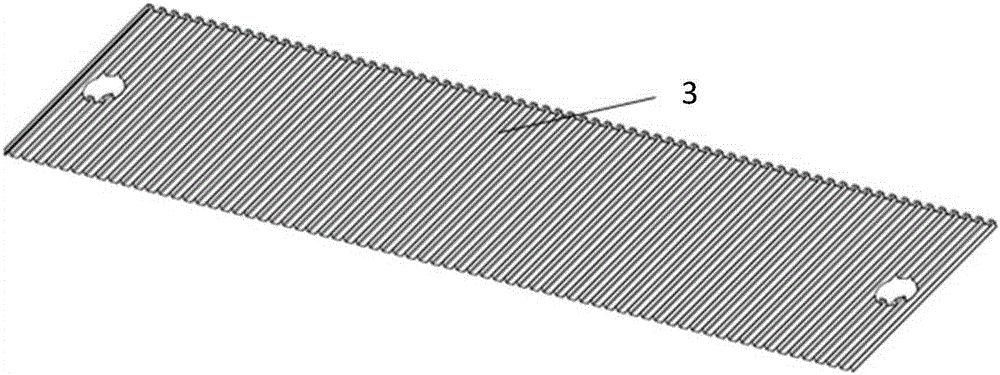

[0038] Such as Image 6 As shown, the integrated metal-graphite composite bipolar plate 12 is composed of a metal corrugated plate 3 and a graphite plate 6 . The metal corrugated plate 3 is the cathode plate, and its structural schematic diagram is as image 3 As shown, the corrugated metal plate 3 is obtained by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com