Method for preparing iron-based prealloy powder

A technology of pre-alloyed powder and pre-alloyed powder, which is applied in the field of preparation of iron-based pre-alloyed powder, can solve problems such as difficult control of sintering temperature, poor cold-press forming ability, complicated sintering process, etc., and achieve easy control and cold-press forming ability Good, simple sintering process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, a kind of preparation method of iron-based pre-alloyed powder, its steps are:

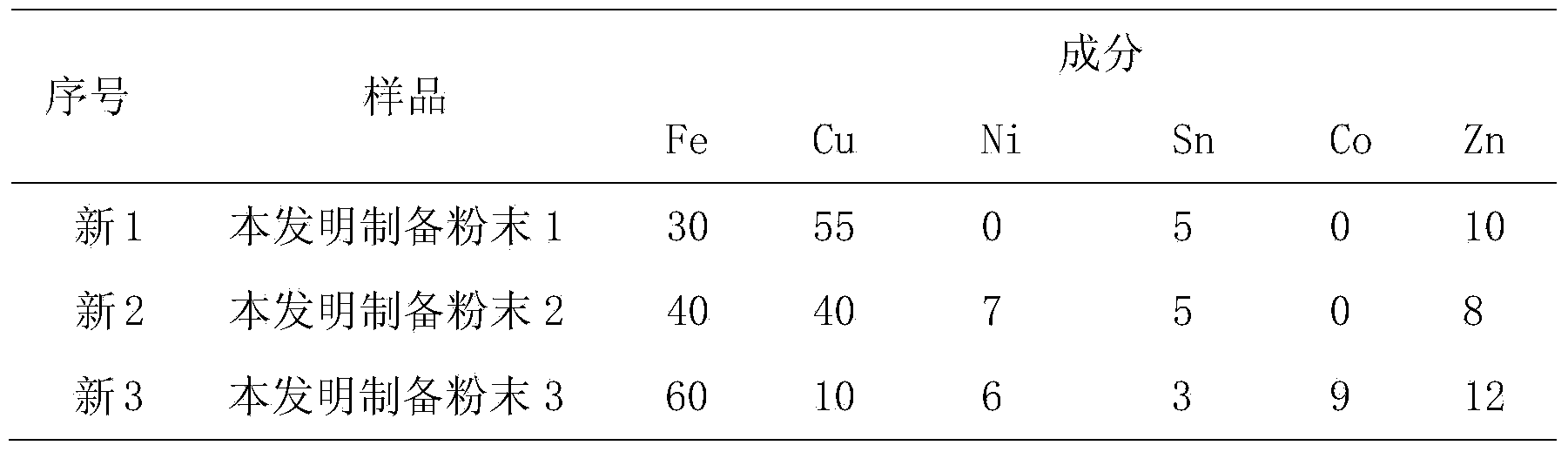

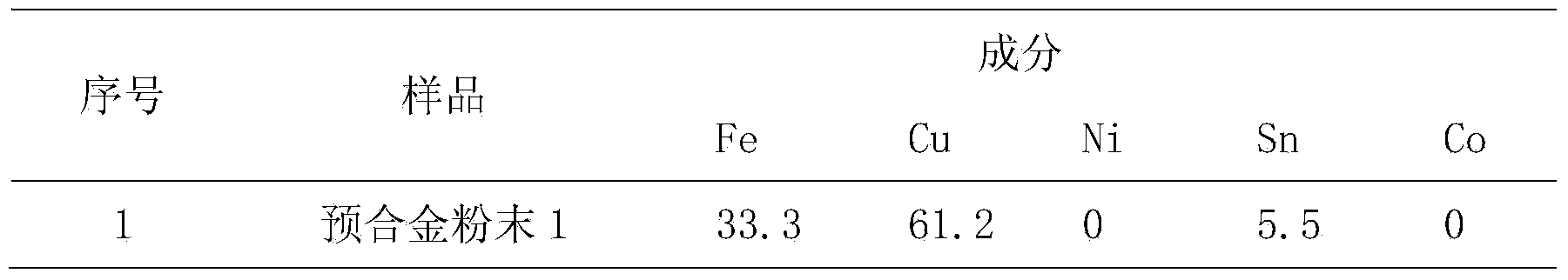

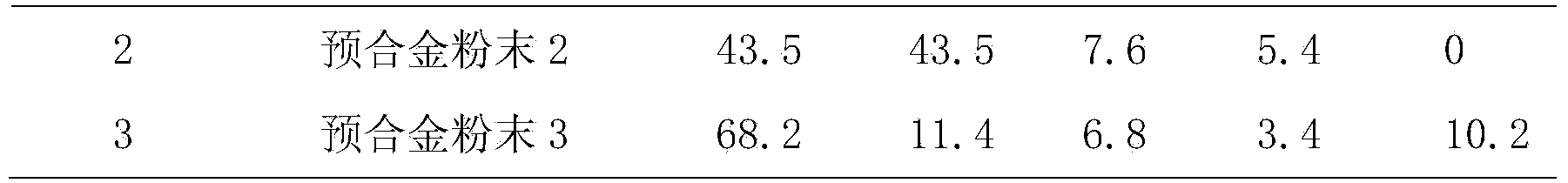

[0030] 1) Pre-alloyed powder prepared by water atomization, element content in alloy powder: Fe mass percentage content is 30% or 40% or 60% or 90%, Cu mass percentage content is 10% or 40% or 55% or 70% %, the rest can be added with Co, Ni, Sn metal elements arbitrarily, and 100-200kg can be prepared, and the melting point does not exceed 1800°C. The iron-based pre-alloyed powder is prepared by using the water atomization complete set of equipment produced by Handan Lande Atomization Powder Manufacturing Equipment Co., Ltd. ;

[0031] 2) Use the SZG series double-cone rotary vacuum dryer to dry the pre-alloyed powder, and the drying temperature is

[0032] 150°C or 180°C or 200°C, drying time is 2h or 3h or 4h;

[0033] 3) The low melting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com