Preparation method of low-oxygen molybdenum alloy and application thereof

A technology of molybdenum alloy and molybdenum powder, which is applied in the direction of metal processing equipment, manufacturing tools, X-ray tube parts, etc., can solve the problem of high oxygen content in molybdenum alloy, achieve high recrystallization temperature, strong toughness at room temperature, and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

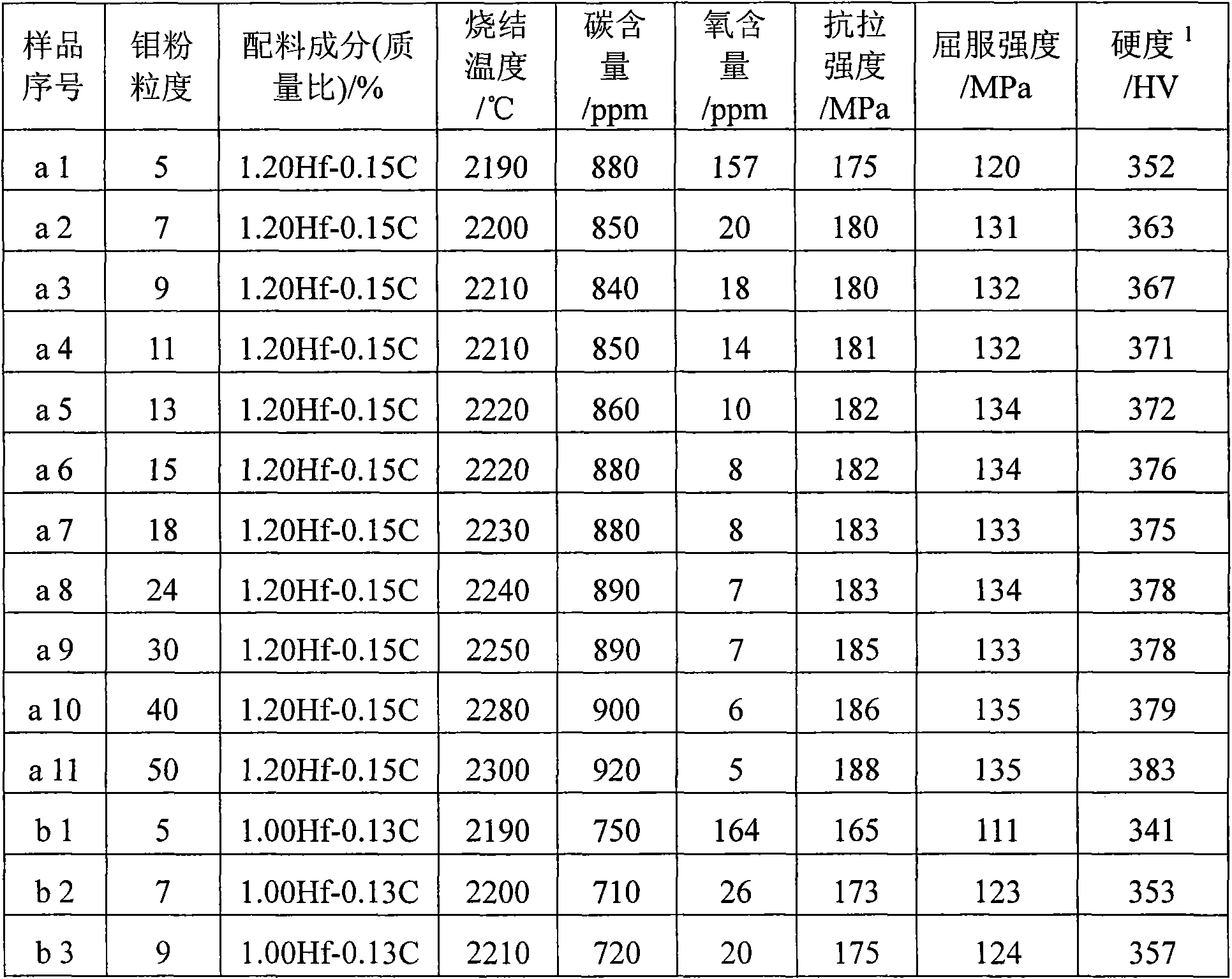

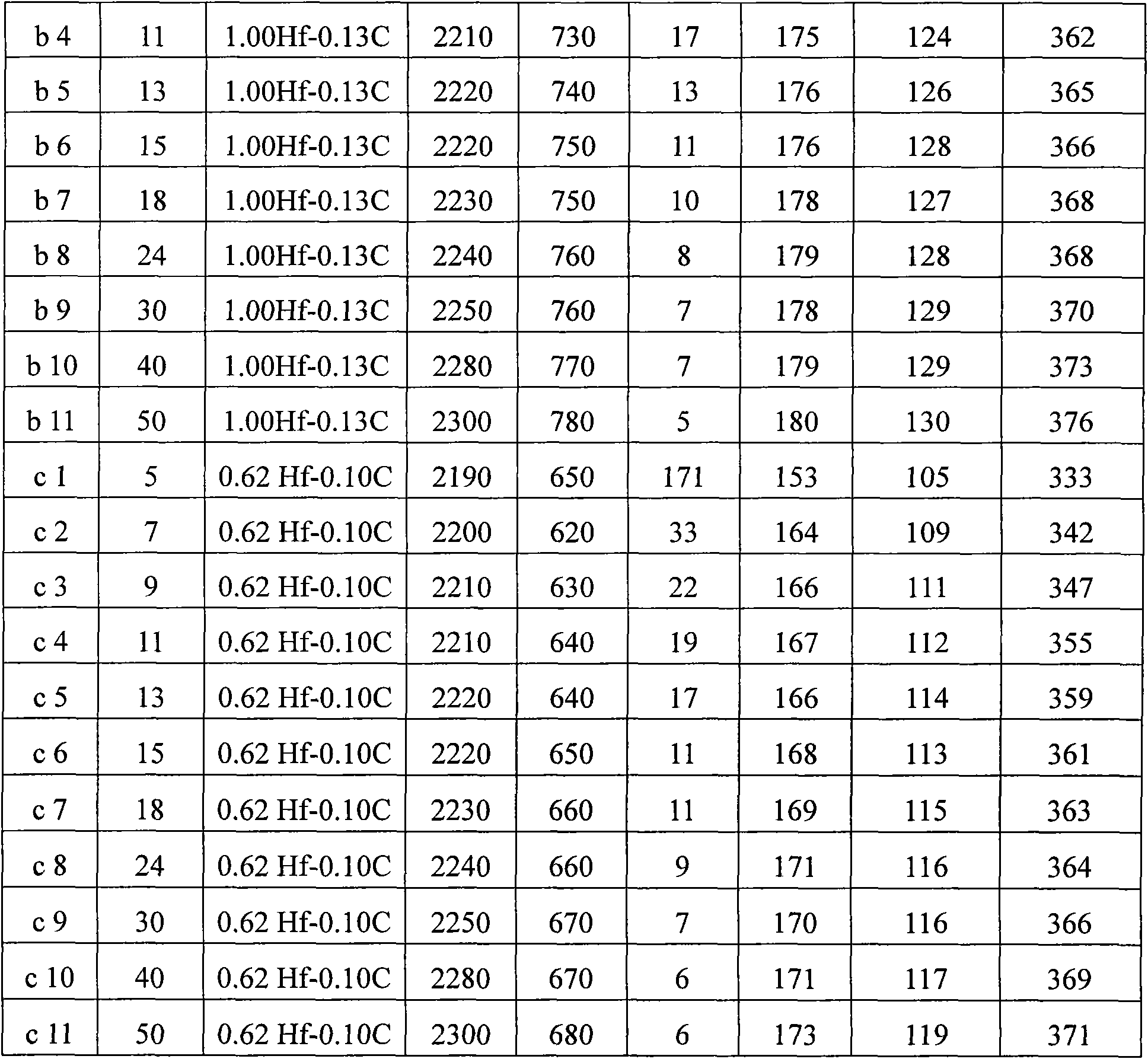

[0027] Comparative test a:

[0028] 1) Take the industrial molybdenum powder with the Fischer particle size of 5 μm, 7 μm, 9 μm, 11 μm, 13 μm, 15 μm, 18 μm, 24 μm, 30 μm, 40 μm, and 50 μm, and the hafnium hydride powder with the Fischer particle size of 3 μm to 10 μm, and the Fischer particle size 0.1 μm ~ 3 μm carbon black. The added mass of hafnium hydride powder is 1.20%, the added mass of carbon black powder is 0.15%, and the rest is molybdenum powder. Mix the selected molybdenum powder, hafnium hydride powder and carbon black powder evenly.

[0029] 2) Raw material forming

[0030] The raw materials uniformly mixed in the step 1) are subjected to static pressure molding under a pressure of 220 MPa to 300 MPa to obtain a blank, and the size of the blank is Φ120mm×130mm.

[0031] 3) Raw material sintering

[0032] Sinter the shaped billet in a hydrogen protective atmosphere. The sintering temperature is shown in the table below. The size of the billet after sintering is...

Embodiment 2

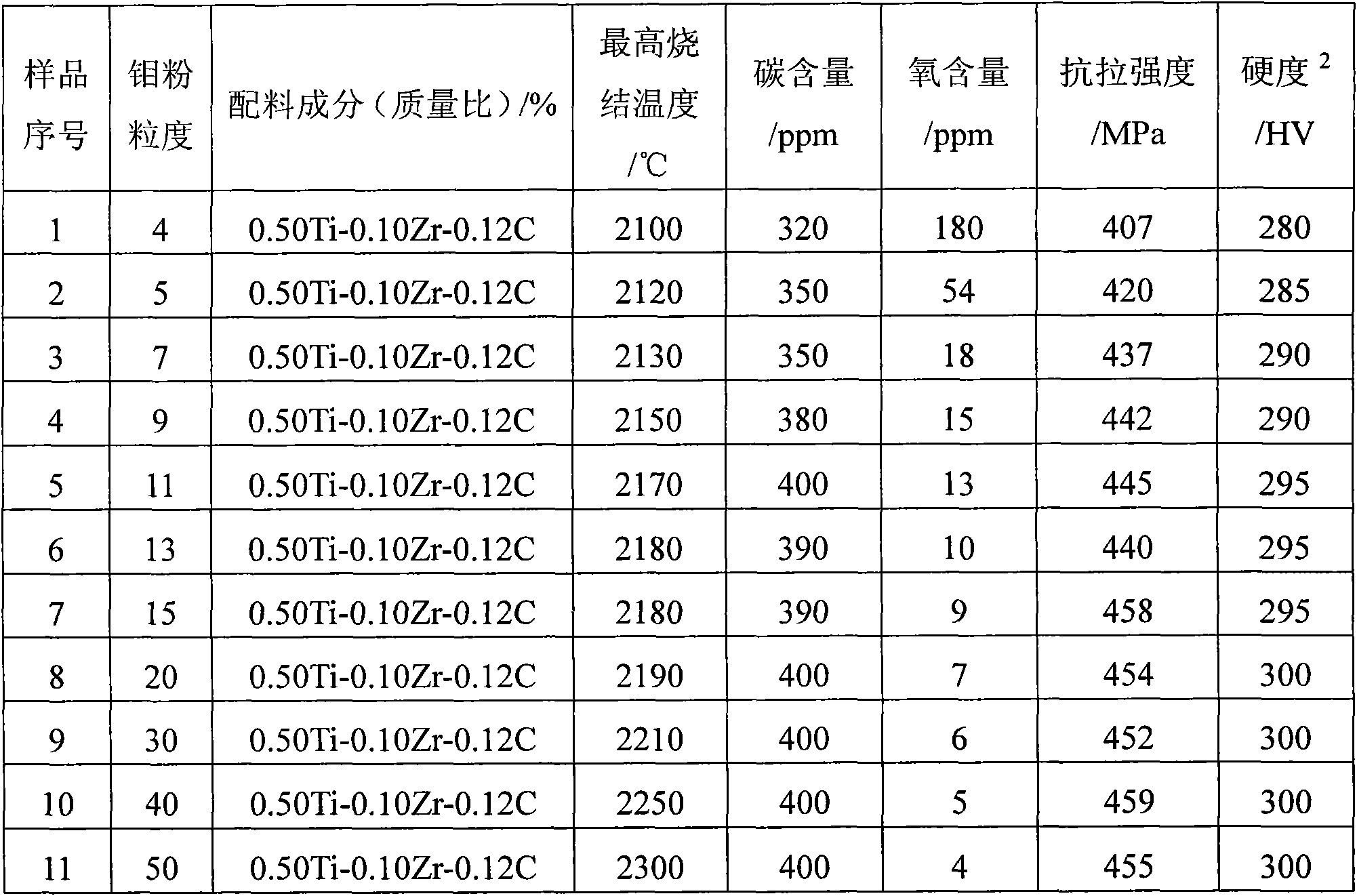

[0053] 1) Take industrial molybdenum powder with a Fisherby particle size of 4 μm, 5 μm, 7 μm, 9 μm, 11 μm, 13 μm, 15 μm, 20 μm, 30 μm, 40 μm, and 50 μm, titanium hydride powder with a Fisher’s particle size of 3 μm to 10 μm, and a Fisherley particle size of 3 μm ~10μm zirconium hydride powder, and carbon black with a Fischer particle size of 0.1μm~3μm. The added mass of titanium hydride powder is 0.50%, the added mass of zirconium hydride powder is 0.10%, the added mass of carbon black powder is 0.12%, and the rest is molybdenum powder. Mix the selected molybdenum powder, titanium hydride, zirconium hydride powder and carbon black powder evenly.

[0054] 2) Raw material forming

[0055] The raw materials uniformly mixed in step 1) are subjected to static pressure molding under a pressure of 200 MPa to obtain a billet, the size of which is Φ120mm×130mm.

[0056] 3) Raw material sintering

[0057] Sinter the shaped billet in a hydrogen protective atmosphere. The sintering te...

Embodiment 3

[0063] 1) Take industrial molybdenum powder with a Fischer particle size of 15 μm, select titanium hydride powder with a Fischer particle size of 3 μm to 10 μm and carbon black powder with a Fischer particle size of 0.1 μm to 3 μm according to the mass ratio of ingredients in the following table, and the rest is molybdenum powder. Mix the selected molybdenum powder, titanium hydride powder and carbon black powder evenly.

[0064] 2) Raw material forming

[0065] The raw materials uniformly mixed in step 1) are subjected to static pressure molding under a pressure of 200 MPa to obtain a billet, the size of which is Φ120mm×130mm.

[0066] 3) Raw material sintering

[0067] The molded blank was sintered in a hydrogen protective atmosphere, the highest sintering temperature was 2180°C, and the size of the blank after 7 sintering was Φ100mm×120mm.

[0068] 4) The sintered billet is forged, and the sample size after forging is Φ230mm×18mm.

[0069] The composition and properties ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com