Q550 D high-quality structural iron medium and heavy plate and production method thereof

A production method and technology for structural steel, applied in the field of steel manufacturing, can solve the problems of shortening the production process, production energy consumption, low production efficiency, complex process, etc., and achieve the effect of shortening the production process, simplifying the production process, and reducing the production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

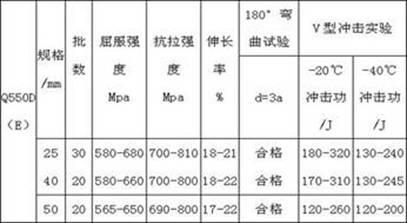

Embodiment 1

[0029] The Q550D high-quality structural steel plate is manufactured with a width of 3800mm and a thickness of 50mm, and is manufactured using the following chemical components in mass percentages: C: 0.03wt%, Si: 0.20wt%, Mn: 1.30wt%, P: 0.010wt%, S: 0.005 wt%, Nb or / and V or / and Ti: 0.05 wt%, Mo: 0.10 wt%, B: 0.05 wt%, Als 0.050 wt%, and the rest is Fe. Carbon equivalent [Ceq=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15]=0.43. Its production method is carried out according to the following steps:

[0030] 1) Perform KR pretreatment on the high-quality molten iron smelted in the open hearth furnace: when the molten iron arrives at the station, the slag before and after the slag must be removed. Lowering 20°C, the desulfurized molten iron contains 0.005 wt% S in mass percentage.

[0031] 2) Converter smelting: the pretreated molten iron is introduced into a 100 / 120 ton top-bottom double-blown converter. It must be ensured that the S content in the molten iron entering the furnace is 0.00...

Embodiment 2

[0039] The Q550D high-quality structural steel plate is manufactured with a width of 3800mm and a thickness of 40mm, and is manufactured using the following chemical components in mass percentages: C: 0.06wt%, Si: 0.30wt%, Mn: 1.50wt%, P: 0.007wt%, S: 0.003wt%, Nb or / and V or / and Ti: 0.13wt%, Mo: 0.15wt%, B: 0.10wt%, Als: 0.030wt%, the rest is Fe. Carbon equivalent [Ceq=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15]: 0.40.

[0040] The production method is basically the same as that in Example 1, the only difference being that in step 1), the thickness of the slag layer on the molten iron surface is 15mm, the desulfurization cycle is 18min, the desulfurization temperature drop is 18°C, and the molten iron after desulfurization contains S 0.004 wt%; in step 2), the S content in the molten iron entering the furnace is 0.004 wt%, the P content is 0.070 wt%, the temperature of the molten iron is 1300°C, and the slagging basicity R control value is 3.0. The carbon content in the molten steel from...

Embodiment 3

[0042] The Q550D high-quality structural steel plate is manufactured with a width of 3800mm and a thickness of 25mm, and is manufactured using the following chemical components in mass percentages: C: 0.09wt%, Si: 0.40wt%, Mn: 1.65wt%, P: 0.005wt%, S: 0.002wt%, Nb or / and V or / and Ti: 0.20wt%, Mo: 0.20wt%, B: 0.15wt%, Als: ≤0.010wt%, the rest is Fe. Carbon equivalent [Ceq=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15]: 0.38.

[0043] The production method is basically the same as that in Example 1, the only difference being that in step 1), the thickness of the slag layer on the molten iron surface is 12mm, the desulfurization cycle is 16min, the desulfurization temperature drop is 14°C, and the molten iron after desulfurization contains S 0.002 wt%; in step 2), the S content in the molten iron entering the furnace is 0.003 wt%, the P content is 0.060 wt%, the temperature of the molten iron is 1360°C, and the slagging basicity R control value is 4.0. The molten steel contains 0.04 wt% of carb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com