A method to improve the hot working performance of mn18cr18n steel

A mn18cr18n, thermal processing technology, applied in the field of metallurgy, can solve problems such as easy cracks, achieve the effect of reducing content, reducing hot embrittlement, and eliminating segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A method for improving hot workability of Mn18Cr18N steel, comprising the following steps:

[0043] Step 1, Ingredients:

[0044] According to the mass ratio, electroslag remelting pre-melting slag: rare earth oxide = 4:1, mix evenly, prepare electroslag remelting rare earth slag, dry; rare earth oxide is Ce 2 o 3 ; The drying process is: at 650 ° C, heat preservation for 8 hours, and slowly cool down with the furnace;

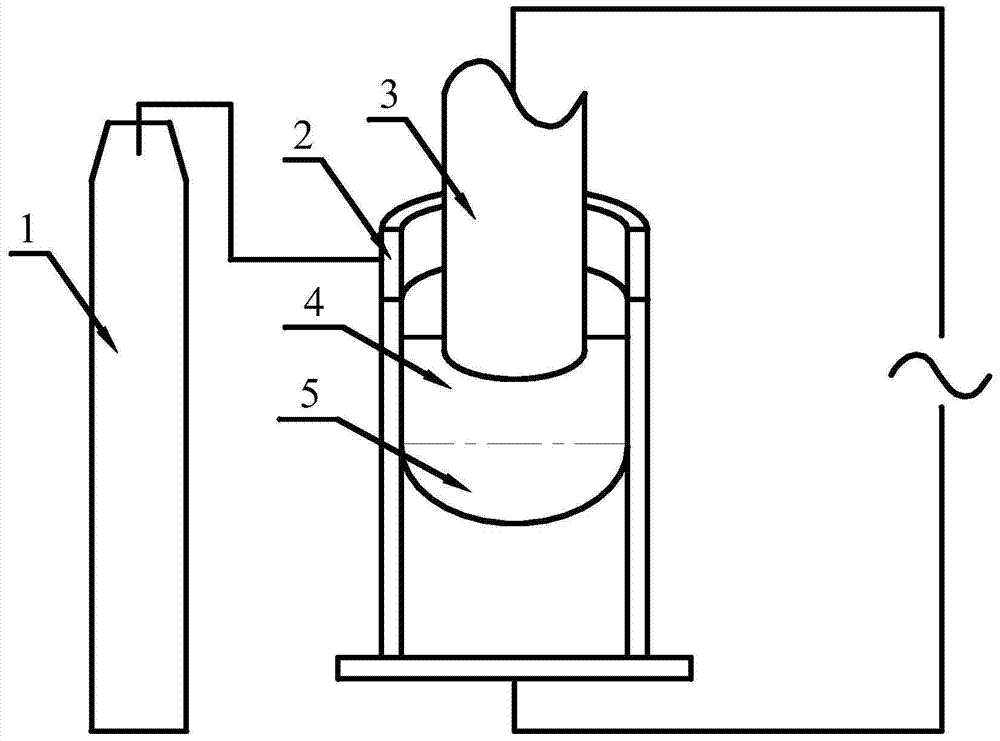

[0045] Step 2, preparation stage for electroslag remelting:

[0046] (1) In the electroslag furnace, place the consumable electrode, crystallizer and arc ignition agent; wherein, the material of the consumable electrode is Mn18Cr18N steel;

[0047] (2) adopt nitrogen protective device, feed in the crystallizer, remove the air in the crystallizer, wherein, the flow rate of nitrogen is 15L / min;

[0048] (3) The quality of electroslag remelting rare earth slag is weighed to be 8kg, and it is configured according to empirical formula (I):

[0049] (4) ...

Embodiment 2

[0056] A method for improving hot workability of Mn18Cr18N steel, comprising the following steps:

[0057] Step 1, Ingredients:

[0058] According to the mass ratio, electroslag remelting pre-melting slag: rare earth oxide = 4:1, mix evenly, prepare electroslag remelting rare earth slag, dry; rare earth oxide is Ce 2 o 3 ; The drying process is: at 750 ° C, heat preservation for 3 hours, and slowly cool down with the furnace;

[0059] Step 2, preparation stage for electroslag remelting:

[0060] (1) In the electroslag furnace, place the consumable electrode, crystallizer and arc ignition agent; wherein, the material of the consumable electrode is Mn18Cr18N steel;

[0061] (2) adopt nitrogen protective device, feed in the crystallizer, remove the air in the crystallizer, wherein, the flow rate of nitrogen is 10L / min;

[0062] (3) The quality of electroslag remelting rare earth slag is weighed to be 8kg, and it is configured according to empirical formula (I):

[0063] (4) ...

Embodiment 3

[0070] A method for improving hot workability of Mn18Cr18N steel, comprising the following steps:

[0071] Step 1, Ingredients:

[0072] According to the mass ratio, electroslag remelting pre-melting slag: rare earth oxide = 3:1, mix evenly, prepare 8kg of electroslag remelting rare earth slag, and dry; the rare earth oxide is La 2 o 3 ; The drying process is: at 700 ° C, keep warm for 4 hours, and slowly cool with the furnace;

[0073] Step 2, preparation stage for electroslag remelting:

[0074] (1) In the electroslag furnace, place the consumable electrode, crystallizer and arc ignition agent; wherein, the material of the consumable electrode is Mn18Cr18N steel;

[0075] (2) adopt nitrogen protective device, feed in the crystallizer, remove the air in the crystallizer, wherein, the flow rate of nitrogen is 10L / min;

[0076] (3) The quality of electroslag remelting rare earth slag is weighed to be 6kg, and it is configured according to empirical formula (I):

[0077] (4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com