Smelting method of chromium-molybdenum steel

A smelting method, the technology of chrome-molybdenum steel, applied in the field of smelting, can solve the problems of poor welding performance and cold bending performance, low plasticity and impact toughness, low oxidation resistance and corrosion resistance of chrome-molybdenum steel, so as to improve plasticity and impact toughness, improve surface quality, reduce porosity and porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

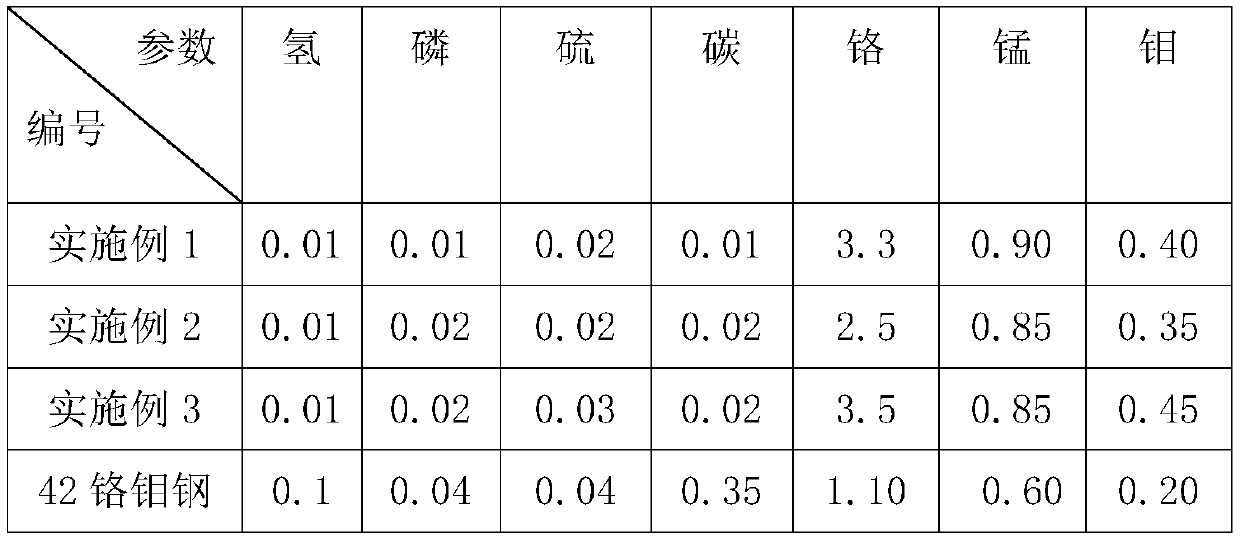

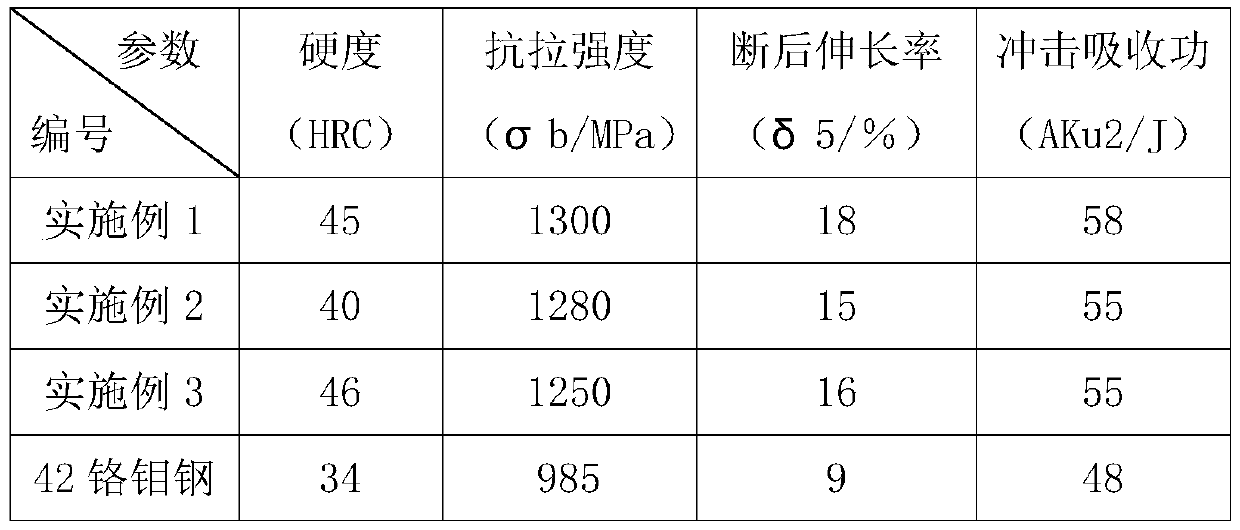

Embodiment 1

[0029] A method for smelting chromium-molybdenum steel, characterized in that it comprises the following steps:

[0030] Step 1, dephosphorization, adding decarburization furnace slag into the molten steel and stirring, then adding an active agent and stirring, blowing the molten steel obtained after stirring for 3-4 minutes;

[0031] Step 2, desulfurization, adding a desulfurizing agent to the molten steel after blowing, the desulfurizing agent component is a strong basic calcium oxide, raising the temperature of the molten steel to 1500 ° C and stirring for 40 minutes;

[0032] Step 3, dehydrogenation, blowing argon in molten steel for 10 minutes after desulfurization, the amount of argon blowing is controlled at 0.5-0.6m 3 / min and stir for 15min, then remove the slag;

[0033] Step 4: Converter boiling tapping, heating up, controlling the final tapping temperature to be 1680±5°C, adjusting the carbon content during tapping to 0.05 parts by weight and the oxygen activity t...

Embodiment 2

[0040] A method for smelting chromium-molybdenum steel, characterized in that it comprises the following steps:

[0041] Step 1, dephosphorization, adding decarburization furnace slag into the molten steel and stirring, then adding an active agent and stirring, blowing the molten steel obtained after stirring for 3-4 minutes;

[0042] Step 2, desulfurization, adding a desulfurizing agent to the molten steel after blowing, the desulfurizing agent component is a strong basic calcium oxide, raising the temperature of the molten steel to 1500 ° C and stirring for 40 minutes;

[0043] Step 3, dehydrogenation, blowing argon in molten steel for 10 minutes after desulfurization, the amount of argon blowing is controlled at 0.5-0.6m 3 / min and stir for 15min, then remove the slag;

[0044] Step 4: Converter boiling tapping, heating up, controlling the final tapping temperature to be 1680±5°C, adjusting the carbon content during tapping to 0.05 parts by weight and the oxygen activity t...

Embodiment 3

[0050] A method for smelting chromium-molybdenum steel, characterized in that it comprises the following steps:

[0051] Step 1, dephosphorization, adding decarburization furnace slag into the molten steel and stirring, then adding an active agent and stirring, blowing the molten steel obtained after stirring for 3-4 minutes;

[0052] Step 2, desulfurization, adding a desulfurizing agent to the molten steel after blowing, the desulfurizing agent component is a strong basic calcium oxide, raising the temperature of the molten steel to 1500 ° C and stirring for 40 minutes;

[0053] Step 3, dehydrogenation, blowing argon in molten steel for 10 minutes after desulfurization, the amount of argon blowing is controlled at 0.5-0.6m 3 / min and stir for 15min, then remove the slag;

[0054] Step 4: Converter boiling tapping, heating up, controlling the final tapping temperature to be 1680±5°C, adjusting the carbon content during tapping to 0.05 parts by weight and the oxygen activity t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com